The polycarbonate filament has many outstanding features, making it suitable for different industries, especially in 3D printing. If you are looking for a material with high heat deflection and impact resistance, PC filament is an ideal option.

So, what is PC filament? Our article will explain the material in detail, how to use it in 3D printing, and introduce our best EuroPlas polycarbonate plastic compound. Scroll down for more!

1. What is Polycarbonate Filament?

The polycarbonate filament is a tough and high-performance material. It's transparent and lightweight yet strong and suitable for high-temperature use. Many industries apply this recyclable thermoplastic in a wide range of professional applications, such as optical applications, electrical and electronic equipment, lighting, and PC 3D printing.

Talking about 3D print polycarbonate, unlike PLA or PETG, two of the easiest polymers to print, the material, with its rigidity and toughness, proves itself a perfect candidate for complex 3D printing applications.

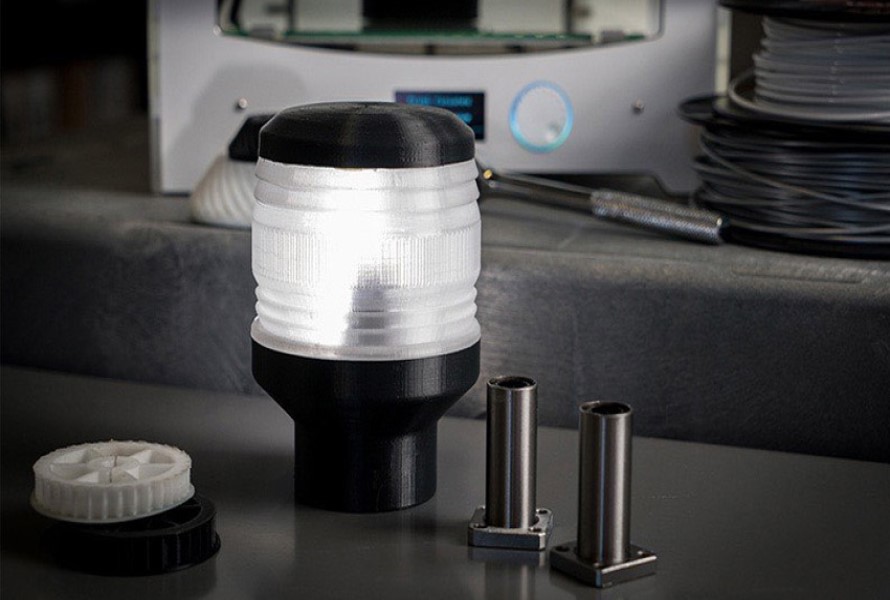

Polycarbonate filament

2. Outstanding Features of PC Filament

Polycarbonate is the result of the polycondensation of phosgene and bisphenol A (a chemical and an organic component). It obtains various valuable properties useful in different industries' applications. The plastic was patented in the 1950s by the German pharmaceutical and agrochemical company Bayer AG. Some of its outstanding features include:

Clear/ Transparent: The polycarbonate filament is naturally transparent and less dense than glass, making it suitable for lighting and optimal applications.

Strong/ Tough with impact-resistant ability: The material can be bent without breaking. Since it's bendable, it's an ideal option for applications requiring little flexibility.

High heat resistant and good flame retardant:

The PC filament temperature withstanding range is high. It has a high glass transition temperature (150°C), meaning its structure will not change until it reaches that temperature. Thus, it's a perfect material for high-temperature applications.

Plus, its Vicat softening point is up to 114°C, and it has a UL 94 rating of V2, showing its valuable heat-resistant and flame-retardant properties. That's why many brands use PC filament for their electrical and electronic products.

3. 3D Printing With Polycarbonate - What to Note?

3.1 . Extrusion Temperature

The suggested extrusion temperature for PC 3D printing is from 260° to 290° C (sometimes, some filaments can even reach 320°C).

3.2 . Bed Temperature

The heat bed or the heated build plate needs to reach a minimum temperature of at least 110°C. The ideal one is 135°C. The pre-drying process should be done with drying time from two to 12 hours so that the material can obtain a moisture content of not more than 0.02%.

The polycarbonate printing temperature can lead to the phenomenon of warping. Therefore, good adhesion to the plate is highly recommended. Plus, applying an extra solution on the tray is strongly advisable to make the first layer more adhesive.

3.3 Printing Speed

The PC 3D printing requires a printing speed of around 10-80 mm/s.

3.4 Heated Chamber

The polycarbonate filament temperature should be stable. It's necessary to have a closed chamber since the temperature fluctuation may lead to cracks or deformations of the products. A cool open-air environment is not allowed for the hot and dried material.

Polycarbonate 3D printer filament

3.5. Storing Condition

One important thing to remember in the polycarbonate 3D printer filament is the material is hygroscopic. It absorbs humidity easily; thus, you should store it in dry and resealable bags or containers to avoid moisture and contamination.

In case the bags are opened, ensure you can seal them again for further storage. Prolonged exposure to UV radiation is not acceptable.

The environment (of low to medium humidity and constant, normal room temperature) during and after printing should be controlled; otherwise, there will be print failures or defective final parts (with reduced properties).

3.6 3D Printer's Configuration

The 3D print polycarbonate materials can be different depending on the brands and strands of the PC. Therefore, the 3D printer's configuration and processing parameters may need to be changed. Operators need to always pay attention to the material manufacturer's recommended printing parameters.

4. Applications for Polycarbonate in 3D printing

In comparison with other thermoplastics on the market, PC filament has more complicated requirements for printing, such as polycarbonate printing temperature or storing conditions. However, many

plastic-addictive companies have high demands for the material, proving its popularity.

It's because its valuable properties are suitable for producing heat-resistant and high-tensile parts. This thermoplastic's resistance to heat, scratches, and shocks makes it perfect for some mechanical parts and molds, such as functional prototypes, hinges, pulley bearings, etc.

Besides, thanks to its inherent transparency, polycarbonate filament is useful and preferable in many applications of the optical sector.

A sample of polycarbonate 3D print

5. Introduction of EuroPlas Polycarbonate Plastic Compound

EuroPlas is an expert company in the masterbatch manufacturing field. We produce different types of engineering compounds with high quality. Our polycarbonate compound meets all the requirements of being lightweight, transparent, strong, durable, and heat resistant. Besides the excellent mechanical and thermal features, EuroPlas Polycarbonate Plastic Compound is made with halogen flame retardant, giving it the ability to resist high temperatures and flame.

It's very convenient to use our product for manufacturing as all functions are integrated into one single material, and you can process directly without any additional materials. It's tailor-made according to the requirements for end-products, giving end-products thermal ability, stiffness, and impact strength improvement.

Regarding safety standards, EuroPlas PC flame retardant compound includes variants with various UL94 standard fireproof levels, including 5VA, 5VB, V0, V1, and V2. That's why our product is a safe choice for high-safety featured applications, such as power sockets, mobile chargers, electronic components, earphones, and keyboards. The fireproof levels of our PC engineering plastic compound can be made according to your needs.

Conclusion

The polycarbonate filament has outstanding features of durability and rigidity, making it an ideal thermoplastic in heat-resistant prints, high-strength parts, optimal applications, and electronic equipment. If you have any questions about the PC compound, contact us right now for the best consultation.