When it comes to engineering materials, polyimide vs polyamide are two commonly used polymers with distinct characteristics and applications. While both belong to the family of polymers, they possess unique properties that make them suitable for different purposes.

In this article, we will delve into the comparison of polyimide vs polyamide, exploring their composition, physical properties, and applications in various industries. By understanding the differences between these materials, you can make informed decisions when choosing the right polymer for your specific project or application. So, let's dive in and explore the unique qualities and applications of polyimide and polyamide materials.

Table of Contents

- What is polyamide?

- What is polyimide?

- What are the differences between polyimide and polyamide?

- Polyimide vs polyamide: When to use each?

- About EuroPlas polyamide (PA) engineering plastic compound

1. What is polyamide?

Polyamide

Polyamide is a versatile synthetic polymer that belongs to the family of polymers known as polyamides. It is commonly referred to as nylon, a term often used interchangeably with polyamide.

Polyamides are categorized as a type of condensation polymer. They are formed through a chemical process called polymerization, where monomers are combined to create long chains of repeating units.

Polyamide production involves the reaction of two main components: a diamine and a dicarboxylic acid. The diamine and the dicarboxylic acid molecules react with each other, resulting in the formation of amide linkages that connect the repeating units together. This polymerization process creates long chains of polyamide.

Polyamide was first synthesized in the late 1930s by Wallace Carothers, a chemist at DuPont. The first polyamide, known as Nylon 6-6, was successfully produced by Carothers. Since then, numerous variations of polyamide have been developed, each with its own unique properties and applications.

Polyamide exhibits a range of desirable properties, including high strength, durability, and resistance to wear and tear. It has excellent tensile strength, allowing it to withstand heavy loads and forces without breaking. Polyamide also possesses good heat resistance and chemical resistance, making it suitable for various demanding environments.

Polyamide finds wide applications across multiple industries. It is commonly used in the textile industry for the production of fabrics, fibers, clothing, and sportswear. Additionally, polyamide is utilized in the automotive sector for manufacturing engine components, gears, and bearings due to its mechanical strength and heat resistance. It is also used in the electrical industry for insulating materials such as cables, connectors, and electrical housings.

2. What is polyimide?

Polyimide

Polyimide is an advanced and versatile thermosetting polymer known for its exceptional thermal stability, mechanical strength, and electrical insulation properties.

Polyimide belongs to the class of polymers known as polyimides, which are classified as thermosetting polymers. They are formed through a chemical process called condensation polymerization. This process involves the reaction of a dianhydride with a diamine to produce a polyamic acid, which is then converted into a polyimide through a process called imidization.

Polyimide production involves a two-step process. First, a dianhydride and a diamine react to form a polyamic acid. This polyamic acid can be processed into various forms such as films or coatings. In the second step, the polyamic acid undergoes imidization, where the acid groups combine to form imide linkages, resulting in a highly stable, crosslinked polyimide structure.

Polyimides were first synthesized and developed in the mid-20th century. The American chemist Paul J. Flory played a significant role in the discovery and advancement of polyimides in the 1950s. Since then, polyimides have been extensively researched and refined to enhance their properties and expand their applications.

Polyimide exhibits exceptional thermal stability, allowing it to maintain its structural integrity even at high temperatures. It also possesses excellent mechanical strength, chemical resistance, and electrical insulation properties. Polyimide films and coatings have low outgassing characteristics, making them suitable for applications in space and vacuum environments.

Polyimide finds widespread use in various industries and applications. In the electronics industry, it is utilized for flexible printed circuit boards (PCBs), wire insulation, and as a protective coating for electronic components due to its excellent electrical insulation properties. Polyimide's high-temperature stability makes it valuable in aerospace applications, such as thermal insulation materials for spacecraft and aircraft components. It is also employed in the automotive sector for engine components and as a protective coating for sensors.

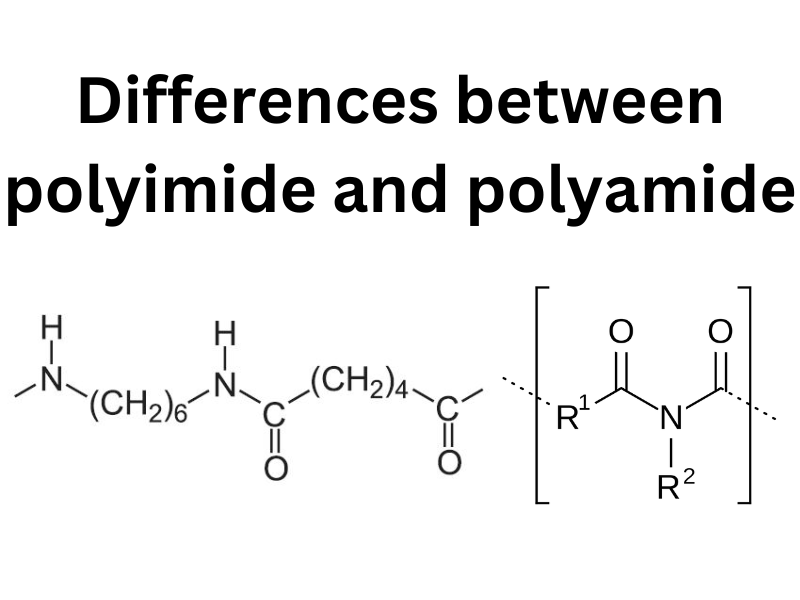

3. What are the differences between polyimide and polyamide?

Differences between polyimide and polyamide

Polyimide vs polyamide are two distinct synthetic polymers that exhibit different properties and find applications in various industries. Understanding the differences between polyimide and polyamide is essential for selecting the appropriate material for specific requirements. Let's compare them in several key aspects:

3.1. Chemical Structure:

The primary difference between polyimide vs polyamide lies in their chemical structures. Polyimide consists of imide linkages (-CONH-) in its backbone, while polyamide contains amide linkages (-CO-NH-) in its chain structure. This structural dissimilarity results in variations in their properties and behaviors.

3.2. Thermal Stability:

Polyimide is renowned for its exceptional thermal stability. It exhibits remarkable resistance to high temperatures, making it suitable for applications that require heat resistance, such as aerospace components and electronic devices. In contrast, while polyamide offers good heat resistance, it generally has lower thermal stability compared to polyimide.

3.3. Mechanical Strength:

Polyimide typically possesses higher mechanical strength than polyamide. Its robust nature enables it to withstand heavy loads and forces, making it suitable for structural applications where strength and durability are essential. Polyamide also exhibits good mechanical properties but generally has lower strength compared to polyimide.

3.4. Electrical Insulation:

Both polyimide vs polyamide exhibit excellent electrical insulation properties. However, due to its unique chemical structure and high-temperature stability, polyimide often surpasses polyamide in terms of electrical insulation performance. Polyimide is commonly used as an insulating material in high-temperature electrical applications, such as wires, cables, and electronic components.

3.5. Applications:

Polyimide vs polyamide find applications in different industries due to their distinct properties. Polyimide is commonly employed in aerospace, electronics, automotive, and semiconductor industries due to its exceptional thermal stability, mechanical strength, and electrical insulation properties. It is used for applications such as insulation films, flexible printed circuit boards, and engine components. Polyamide, on the other hand, is widely used in the textile industry for fabrics, clothing, and sportswear, as well as in automotive components, electrical insulation, and engineering materials.

4. Polyimide vs polyamide: When to use each?

When to use polyimide vs polyamide?

4.1. Temperature Resistance:

Polyimide is the preferred choice when high-temperature resistance is required. It can withstand extreme temperatures without significant degradation, making it suitable for applications in aerospace, electronics, and automotive industries, where exposure to heat is a concern. On the other hand, polyamide offers good heat resistance but may not perform as well as polyimide at very high temperatures.

4.2. Mechanical Strength:

When it comes to mechanical strength, polyimide tends to outperform polyamide. Polyimide exhibits excellent tensile strength and durability, making it ideal for structural applications that require high-strength materials. Polyamide also possesses good mechanical properties, but it may not be as robust as polyimide in demanding load-bearing applications.

4.3. Electrical Insulation:

Both polyimide and polyamide offer excellent electrical insulation properties. However, if high-temperature electrical insulation is required, polyimide is often the preferred choice due to its exceptional thermal stability. Polyimide is commonly used in applications such as wires, cables, and electronic components where reliable insulation at elevated temperatures is crucial. Polyamide, on the other hand, is suitable for electrical insulation in less demanding temperature environments.

4.4. Chemical Resistance:

Polyimide generally exhibits better chemical resistance compared to polyamide. It can withstand exposure to various chemicals without significant degradation, making it suitable for applications in harsh chemical environments. Polyamide, while offering reasonable chemical resistance, may be susceptible to certain chemicals and solvents. Therefore, polyimide is recommended when superior chemical resistance is required.

4.5. Cost Considerations:

Polyimide is generally more expensive compared to polyamide due to its advanced properties and specialized manufacturing processes. Polyamide, being more cost-effective, is often chosen for applications where a balance between performance and cost is essential.

In conclusion, choosing between polyimide vs polyamide depends on the specific requirements of the application. Polyimide excels in high-temperature resistance, mechanical strength, electrical insulation at elevated temperatures, and chemical resistance, making it suitable for demanding applications. Polyamide, on the other hand, offers good heat resistance, mechanical properties, and electrical insulation at lower temperatures, making it a cost-effective choice for various industries. Assessing the temperature range, mechanical demands, electrical properties, chemical exposure, and budgetary constraints will help determine whether polyimide or polyamide is the optimal choice for a particular application.

Polyamide (PA) engineering plastic compound

At EuroPlas, we take great pride in being a leading masterbatch manufacturer in Vietnam, specializing in the production of high-quality polyamide (PA) engineering plastic compounds. With our unwavering commitment to excellence, we have established ourselves as a trusted partner for industries seeking reliable plastic solutions.

As experts in the field, we focus on the production of top-notch PA engineering plastic compounds that meet and exceed industry standards. Our advanced manufacturing facilities, combined with stringent quality control measures, ensure the consistent delivery of exceptional products.

EuroPlas' PA engineering plastic compounds are carefully crafted using cutting-edge production techniques. Our dedicated team of professionals follows strict protocols throughout the manufacturing process to ensure optimal quality and reliability. We understand the importance of dependable materials in the production cycle, and that's why we prioritize precision and consistency in every batch.

Our customer-centric approach sets us apart. We strive to build long-term partnerships based on trust, reliability, and outstanding customer service. Our team of experts is always ready to provide technical support, guidance, and customized solutions to meet your specific requirements.

Contact EuroPlas today to learn more about our high-quality polyamide (PA) engineering plastic compounds. Experience the difference of partnering with a trusted industry leader.