When it comes to comparing polyolefin vs polyethylene, understanding their similarities and differences is crucial. Polyolefin is a broad term encompassing various polymers derived from olefins, while polyethylene specifically refers to polymers derived from ethylene. Both materials share similarities such as excellent chemical resistance, versatility, and environmental sustainability.

However, they also have distinct characteristics that set them apart, including composition, density variations, mechanical strength, and specific applications. By delving deeper into the comparison of polyolefin vs polyethylene, we can gain valuable insights into their properties and make informed decisions when selecting the most suitable material for specific applications.

Table of Contents

- What is polyolefin?

- What is polyethylene?

- Polyolefin vs polyethylene: Similarities and differences

- EuroPlas masterbatch for polyolefin plastic products

1. What is polyolefin?

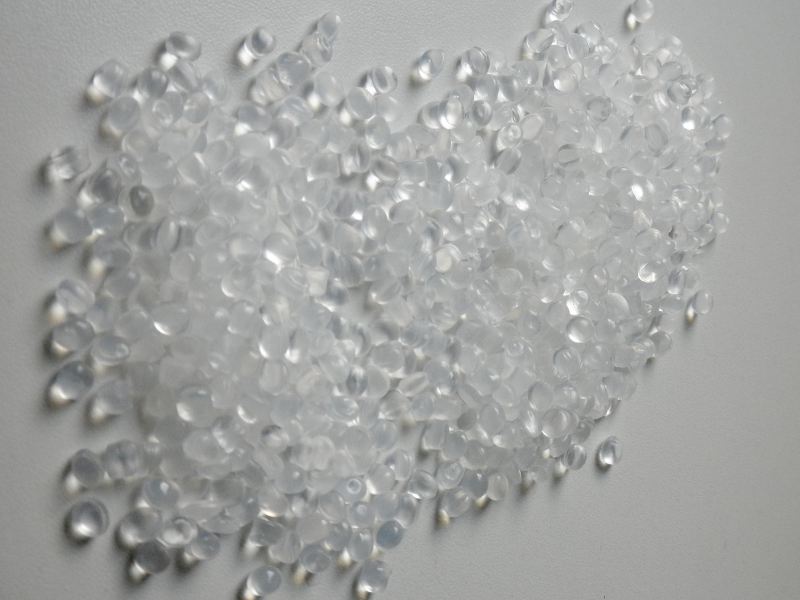

Polyolefin

Polyolefin is a term that refers to a class of polymers made from olefins, which are hydrocarbons with a double bond between two carbon atoms. Polyolefins are versatile and widely used in various industries due to their excellent physical and chemical properties. They are known for their durability, flexibility, and resistance to chemicals, moisture, and UV radiation.

Polyolefins are typically classified into two main types: homopolymers and copolymers. Homopolymers are composed of a single type of olefin, such as polypropylene (PP) or polyethylene (PE), while copolymers are made up of two or more different olefins. The most common copolymers include ethylene-propylene (EP) and ethylene-vinyl acetate (EVA).

Polyolefins have a wide range of applications across various industries, including packaging, automotive, construction, textiles, and medical. They are used to make a variety of products such as plastic films, containers, pipes, automotive parts, and even surgical implants. Due to their versatility, polyolefins are often compared to another popular polymer called polyethylene.

2. What is polyethylene?

Polyethylene

Polyethylene (PE) is a type of polyolefin and one of the most commonly used plastics worldwide. It is derived from ethylene, which is a colorless gas obtained from petroleum or natural gas. Polyethylene is known for its excellent strength, toughness, and chemical resistance.

PE is classified into several different types based on its density and molecular structure. The two main categories are high-density polyethylene (HDPE) and low-density polyethylene (LDPE). HDPE has a higher density and stronger intermolecular forces, making it more rigid and suitable for applications requiring stiffness and strength. LDPE, on the other hand, has a lower density and is more flexible and pliable, making it ideal for applications where flexibility is important.

Polyethylene is widely used in packaging, particularly for plastic bags, bottles, and containers. It is also used in various other industries, including agriculture, construction, electrical, and healthcare. Its versatility, affordability, and excellent chemical resistance make it a popular choice for a wide range of applications.

In the next sections of this blog, we will delve deeper into the similarities and differences between polyolefin vs polyethylene, highlighting their unique characteristics, properties, and applications. By understanding the distinctions between these two polymers, we can gain valuable insights into their optimal use in various industries.

3. Polyolefin vs polyethylene: Similarities and differences

3.1. Similarities between polyolefin vs polyethylene

Polyolefin and polyethylene share several similarities due to their classification and chemical composition:

1. Polymer Classification:

Both polyolefin and polyethylene belong to the class of polymers known as olefins, making them part of the broader category of polyolefins. Olefins are hydrocarbons with a double bond between two carbon atoms. This common classification is the foundation for many of their shared properties. When comparing polyolefin vs polyethylene, it's important to recognize that polyethylene is a specific type of polyolefin, focusing solely on ethylene-based polymers.

2. Chemical Resistance:

One of the notable similarities between polyolefin and polyethylene in the context of polyolefin vs polyethylene is their excellent resistance to chemicals. They both exhibit inherent resistance to acids, bases, solvents, and various other chemicals, making them suitable for applications where contact with corrosive substances is expected. This chemical resistance contributes to their durability and longevity in demanding environments, a quality that is essential when considering the use of polyolefin vs polyethylene in various industries.

3. Versatility:

Both polyolefin and polyethylene are highly versatile polymers in the comparison of polyolefin vs polyethylene, finding applications across numerous industries. Their adaptability stems from their ability to be easily molded, extruded, and formed into different shapes and sizes. Polyolefins and polyethylenes can be processed using various techniques, such as injection molding, blow molding, and film extrusion, allowing for a wide range of applications. This versatility in both polyolefin and polyethylene makes them suitable choices for various industries, including packaging, automotive components, construction materials, and medical devices.

4. Environmental Impact:

Both polyolefin and polyethylene can have positive environmental attributes when considering polyolefin vs polyethylene. For instance, certain types of polyethylene, such as high-density polyethylene (HDPE), are recyclable and can be used to produce new plastic products. Similarly, specific polyolefins can be recycled or manufactured from renewable resources, reducing the reliance on fossil fuels. The ability to recycle and use sustainable feedstocks contributes to the environmental sustainability of both polyolefin and polyethylene, making them favorable choices in the context of polyolefin vs polyethylene comparisons.

3.2. Differences between polyolefin vs polyethylene

While polyolefin and polyethylene share similarities, they also have distinct characteristics that set them apart:

1. Composition:

Polyolefin is a broader term that encompasses various types of polymers derived from different olefins, whereas polyethylene specifically refers to polymers derived from ethylene. When comparing polyolefin vs polyethylene, it's important to note that polyethylene is a specific type of polyolefin, focusing solely on ethylene-based polymers. This distinction emphasizes the specific composition of polyethylene compared to the broader range of polymers that fall under the category of polyolefin.

2. Density:

Polyethylene exhibits different densities based on its molecular structure. In the context of polyolefin vs polyethylene, it is crucial to note that high-density polyethylene (HDPE) has a higher density and stronger intermolecular forces, resulting in a more rigid material. In contrast, low-density polyethylene (LDPE) has a lower density and is more flexible and pliable. This difference in density affects the mechanical properties and applications of the respective polyethylene types, making them suitable for different purposes.

3. Mechanical Strength:

The mechanical strength of polyolefin and polyethylene can vary. While both materials offer good strength, polyethylene, particularly HDPE, tends to have higher tensile strength and stiffness compared to other polyolefins. In the comparison of polyolefin vs polyethylene, it's important to recognize that this higher tensile strength and stiffness make HDPE more suitable for applications requiring structural integrity and load-bearing capacity. On the other hand, polyolefins like polypropylene may exhibit higher impact resistance and flexibility, making them ideal for applications where toughness and flexibility are critical.

4. Applications:

Although both polyolefin and polyethylene have broad application ranges, there are specific areas where they excel in the context of polyolefin vs polyethylene comparisons.

Polyethylene, with its various densities and flexibility, is commonly used in packaging materials, plastic bags, films, and containers. Its ability to be easily processed and its good barrier properties make it a preferred choice for packaging applications.

Polypropylene, a type of polyolefin, finds applications in automotive parts, textiles, medical devices, and more. Its mechanical properties, chemical resistance, and heat resistance make it suitable for various demanding applications.

Understanding the similarities and differences between polyolefin and polyethylene in the context of polyolefin vs polyethylene enables us to make informed decisions regarding their selection and utilization in various industries.

4. EuroPlas masterbatch for polyolefin plastic products

At EuroPlas, we take pride in being a leading masterbatch manufacturer in Vietnam, specializing in providing high-quality solutions for polyolefin plastic products. With our state-of-the-art facilities and expertise in the field, we are committed to delivering exceptional masterbatch formulations that enhance the performance and aesthetics of your plastic products.

EuroPlas offers high-quality filler masterbatch solutions for polyolefin plastic products. Our filler masterbatches are specifically designed to improve the mechanical properties of polyolefins such as polyethylene (PE) and polypropylene (PP). By incorporating carefully selected fillers into the polyolefin matrix, our masterbatches enhance stiffness, impact resistance, and dimensional stability.

With EuroPlas filler masterbatch, you can optimize the cost-effectiveness of your plastic products without compromising on performance. Our masterbatch ensures excellent processability and allows for efficient production.

We prioritize quality in every step of our manufacturing process, from sourcing premium fillers to conducting thorough quality control checks. EuroPlas filler masterbatch provides consistent and reliable results, ensuring that your polyolefin plastic products meet the highest standards.

EuroPlas is your trusted partner for high-quality color masterbatch solutions for polyolefin plastic products. Our color masterbatches are designed to provide vibrant and consistent colors, enhancing the visual appeal of your polyolefin-based items.

Using advanced manufacturing techniques, we ensure superior dispersion and color accuracy in our masterbatches. EuroPlas color masterbatches are available in a wide range of standard colors, and we can also create custom colors to meet your specific requirements.

With our color masterbatch, you can achieve the desired shade and tone for your polyolefin plastic products, maintaining brand identity and product aesthetics. EuroPlas color masterbatches are developed with a focus on quality, enabling you to create eye-catching and visually appealing items that stand out in the market.

EuroPlas offers a comprehensive range of high-quality plastic additives for polyolefin plastic products. Our additives are carefully formulated to enhance various performance aspects of polyolefins, including UV resistance, flame retardancy, antistatic properties, and more.

We understand the importance of tailored solutions, and our team of experts can help you choose the right additives to meet your specific requirements. EuroPlas plastic additives are designed to improve the durability, safety, and functionality of your polyolefin-based items.

With our commitment to quality, you can trust that our plastic additives undergo rigorous testing and meet industry standards. EuroPlas provides reliable and effective solutions that enhance the performance and value of your polyolefin plastic products.

If you're looking for high-quality masterbatch for your polyolefin plastic products, EuroPlas is here to assist you. Reach out to our knowledgeable team today to discuss your requirements, explore our range of masterbatch options, and discover how EuroPlas can elevate the performance and aesthetics of your plastic products. So what are you waiting for? Contact us now to start a fruitful collaboration for your next projects!