When it comes to selecting the right material for your project, strength plays a crucial role. In this article, we will compare two popular thermoplastics, polystyrene vs polypropylene, to determine which one offers superior strength. By understanding their unique properties and applications, you can make an informed decision for your specific requirements.

1. Basic understanding about Polystyrene

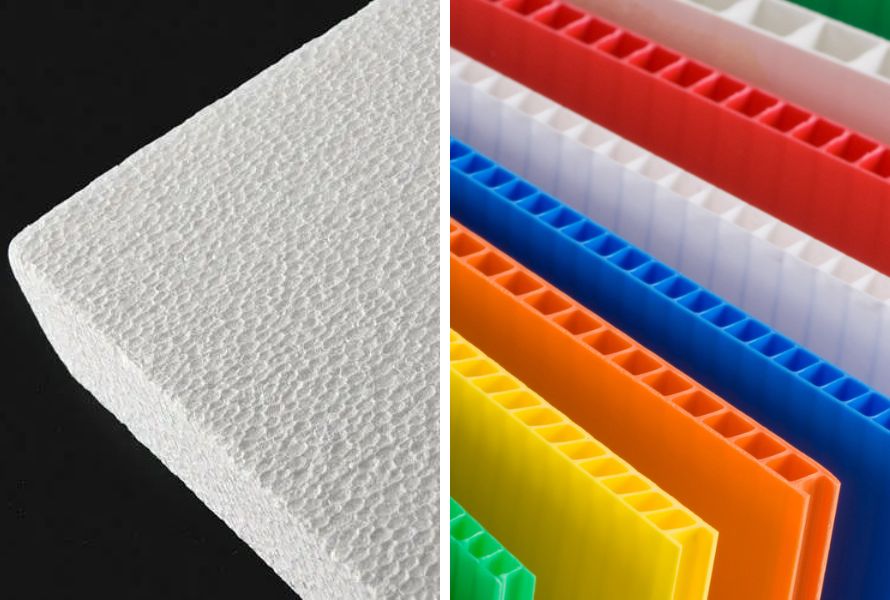

Polystyrene is a synthetic polymer made from the monomer styrene. It is a flexible and extensively utilized plastic material that is renowned for being transparent and stiff. Polystyrene is commonly used in various applications, including packaging materials, disposable food containers, insulation, and consumer products.

Read more: Everything you need to know about polystyrene

A synthetic polymer called polystyrene is created from the styrene monomer

2. Basic understanding about polypropylene

The thermoplastic polymer polypropylene (PP) is a member of the polyolefin family. It is a versatile and widely used plastic material known for its excellent combination of properties. polypropylene is produced through the polymerization of propylene monomers.

Read more: PP Plastic: Everything you need to know

A thermoplastic polymer from the polyolefin family, polypropylene (PP) is used in many products.

3. Comparison of Polystyrene vs polypropylene

Here is a short comparing table Polystyrene vs polypropylene:

| Properties |

Polystyrene |

Polypropylene |

| Density |

Low to Moderate |

Low to Moderate |

Transparency

|

Transparent or Translucent |

Translucent or Opaque |

| Melting Point |

240-260°C (464-500°F) |

160-170°C (320-338°F)

|

| Tensile Strength |

Low to Moderate |

High

|

| Flexural Strength |

Moderate |

High

|

Impact Strength

|

Low to Moderate |

High |

Compressive Strength

|

Moderate |

High |

Stiffness

|

Low to Moderate |

High |

| Heat Resistance |

Low |

High |

| Chemical Resistance |

Moderate

|

High |

| Moisture Resistance |

Moderate

|

High |

| Electrical Insulation |

Good

|

Excellent |

Recyclability

|

Some types are recyclable |

Highly Recyclable

|

3.1. Polystyrene vs polypropylene: Density

- Polystyrene (PS) is a plastic material that commonly exhibits a low to moderate density. The density of Polystyrene ranges from around 1.04 to 1.07 g/cm³. This means that Polystyrene is relatively lightweight for its volume. The low density of Polystyrene contributes to its advantageous properties such as good buoyancy and insulation capabilities.

- On the other hand, polypropylene (PP) is a plastic material that also has a low to moderate density. The density of polypropylene generally ranges from around 0.89 to 0.91 g/cm³. This makes polypropylene slightly lighter in weight compared to Polystyrene for the same volume. The lower density of polypropylene contributes to its desirable properties such as high strength-to-weight ratio and excellent impact resistance.

3.2. Polystyrene vs polypropylene: Transparency

- Polystyrene (PS) can be a plastic material that varies in strength. Depending on the grade and formulation, Polystyrene can range from transparent to translucent in appearance. Transparent Polystyrene allows light to pass through with minimal distortion, making it suitable for applications where clarity is desired.

- Contrarily, polypropylene (PP) has an opaque or translucent appearance. Comparatively to Polystyrene, polypropylene appears milky or hazy, making it less transparent. While some grades of polypropylene may have improved transparency, in general, it is not as optically clear as Polystyrene. polypropylene's translucent or opaque nature makes it suitable for applications where light transmission is not a primary requirement.

3.3. Polystyrene vs polypropylene: Melting Point

- Polystyrene is a thermoplastic polymer with a relatively low melting point. The melting point of polystyrene normally ranges from around 240 to 260 degrees Celsius (464 to 500 degrees Fahrenheit). This temperature range is relatively low compared to other thermoplastics.

- Polypropylene is also a thermoplastic polymer but has a lower melting point compared to polystyrene. The melting point of polypropylene is usually between 130 and 171 degrees Celsius (266 and 340 degrees Fahrenheit). It has a broader range due to the different molecular structures and variations in the manufacturing process.

While polypropylene and polystyrene are both thermoplastic polymers, polypropylene has a lower melting point

3.4. Polystyrene vs polypropylene: Tensile Strength

- Polystyrene (PS) typically exhibits a lower tensile strength compared to polypropylene. Polystyrene is a relatively brittle material, meaning it has limited resistance to deformation under tension. While it can withstand moderate loads, Polystyrene is more susceptible to breaking or fracturing when subjected to high stress or strain. Therefore, its tensile strength may not be as high as that of other materials.

- Plypropylene (PP) generally has a higher tensile strength in comparison to Polystyrene. polypropylene is known for its excellent tensile strength, which refers to its ability to resist deformation or breaking under tension. It can withstand higher loads and exhibits better toughness and resilience compared to Polystyrene.

3.5. Polystyrene vs polypropylene: Flexural Strength

- Polystyrene generally has lower flexural strength compared to polypropylene. The flexural strength of polystyrene can vary depending on factors such as molecular weight, processing conditions, and the presence of additives. Typically, the flexural strength of polystyrene ranges from around 50 to 80 MPa (megapascals).

- On the other hand, polypropylene is well recognized for its strong flexural strength. It has a stronger flexural strength than polystyrene. polypropylene's flexural strength normally varies from 50 to 100 MPa, however it can be greater depending on the grade and manufacturing process.

3.6. Polystyrene vs polypropylene: Impact Strength

- Polystyrene has relatively lower impact strength compared to polypropylene. It is a brittle material, meaning it is more prone to fracture or break under sudden impact or stress. The impact strength of polystyrene frequently ranges from around 0.6 to 1.5 kJ/m^2 (kilojoules per square meter).

- However, the impact strength can be improved by adding impact modifiers or reinforcing agents.

polypropylene exhibits higher impact strength compared to polystyrene. It is a tough and resilient material, capable of withstanding impacts without breaking easily. The impact strength of polypropylene regularly ranges from around 3 to 25 kJ/m^2, depending on the specific grade and formulation.

The impact strength of polystyrene is comparatively lower than that of polypropylene

3.7. Polystyrene vs polypropylene: Compressive Strength

- Comparatively to polypropylene, polystyrene typically has a lesser compressive strength. Polystyrene has a decreased resistance to compression and a comparatively low density. Polystyrene generally has a compressive strength between 0.7 and 1.4 MPa (megapascals).

- Polypropylene has a stronger compressive strength than polystyrene. It is a more stiff and long-lasting material that can handle larger compression loads. polypropylene compressive strength mostly ranges between 20 and 50 MPa, depending on the grade and formulation.

3.8. Polypropylene vs Polystyrene: Stiffness

- Polypropylene (PP) is known for its relatively high stiffness. It has a rigid and firm nature, allowing it to resist bending and deformation under applied loads. This stiffness gives polypropylene structural integrity, making it suitable for applications where rigidity and dimensional stability are important factors.

- Polystyrene (PS) generally has a lower stiffness compared to polypropylene. It is a more flexible and less rigid material, allowing for some bending and deformation under applied loads. Polystyrene's lower stiffness can be advantageous in applications where some flexibility or impact resistance is desired.

3.9. Polypropylene vs Polystyrene: Heat Resistance

- Polypropylene (PP) exhibits good heat resistance properties. It has a relatively high melting point. polypropylene can withstand elevated temperatures without significant deformation or loss of mechanical properties. It retains its shape and strength even when exposed to higher temperatures, making it suitable for applications that require heat resistance, such as automotive components, electrical enclosures, and food containers.

- Meanwhile, Polystyrene (PS) has lower heat resistance compared to polypropylene. Polystyrene can soften and deform at relatively lower temperatures compared to polypropylene. As a result, it is less suitable for applications that require prolonged exposure to high temperatures.

Polypropylene (PP) is more heat resistant than Polystyrene (PS)

3.10. Polypropylene vs Polystyrene: Chemical Resistance

- Polypropylene is extremely chemically resistant. It is extremely resistant to a variety of substances, including acids, bases, solvents, and oils. polypropylene is well-known for its resistance to chemical assault and degradation, making it ideal for applications involving harsh chemicals.

- Polystyrene has more limited chemical resistance compared to polypropylene. While it is generally resistant to water and aqueous solutions, polystyrene can be susceptible to attack by some organic solvents, strong acids, and bases. It is important to consider the specific chemical environment when using polystyrene, as it may not be suitable for applications involving aggressive chemicals.

3.11. Polypropylene vs Polystyrene: Moisture Resistance

- Polypropylene has good moisture resistance. It is generally resistant to water absorption and does not easily degrade or experience significant dimensional changes when exposed to moisture or humid environments. This makes polypropylene suitable for applications where moisture resistance is important, such as in outdoor or wet environments.

- Polystyrene has limited moisture resistance compared to polypropylene. It can absorb moisture over time, which may lead to dimensional changes, warping, or degradation of its properties. Polystyrene is more susceptible to the effects of moisture, and prolonged exposure to high humidity or water can impact its performance.

3.12. Polypropylene vs Polystyrene: Electrical Insulation

- Polypropylene is an excellent electrical insulator. It has high resistivity and low dielectric constant, making it suitable for electrical insulation applications. polypropylene is commonly used as an insulating material in capacitors, electrical cables, and other electrical components. It exhibits good electrical insulation performance even at high temperatures.

- Polystyrene is also a good electrical insulator. It has high resistivity and low dielectric constant, similar to polypropylene. Polystyrene is often used as an insulating material in electronic devices, insulation boards, and packaging for sensitive electronic components. It provides reliable electrical insulation and can withstand moderate voltage levels.

3.13. Polypropylene vs Polystyrene: Environmental Sustainability

- Polypropylene is considered to have relatively better environmental sustainability compared to polystyrene. It is a thermoplastic material that can be easily recycled, and many recycling facilities accept polypropylene for processing. Recycled polypropylene can be used to produce new products, reducing the demand for virgin plastic. Additionally, polypropylene has a lower carbon footprint compared to polystyrene during its production process.

- Compared to polypropylene, polystyrene is often thought to be less ecologically friendly. Due to its low recycling rates and a small market for recycled polystyrene, traditional polystyrene, also known as expanded polystyrene (EPS) or Styrofoam, is not often accepted for recycling. It contributes to plastic pollution since it takes a long time to biodegrade in the environment. Through specialized recycling facilities, there are initiatives to recycle and reuse polystyrene trash.

3.14. Polypropylene vs Polystyrene: Recyclability

- Polypropylene is generally more recyclable compared to polystyrene. It is a thermoplastic material that can be melted and reprocessed multiple times without significant degradation in its properties. Many recycling facilities accept polypropylene for recycling, and there are established markets for recycled polypropylene. It can be recycled into various products, including packaging materials, automotive components, and household items.

- Polystyrene recycling is more challenging compared to polypropylene. Traditional polystyrene, especially expanded polystyrene (EPS) or foam, faces lower recycling rates due to factors such as collection challenges, low market demand for recycled polystyrene, and the need for specialized recycling facilities. However, there are specialized recycling processes available for polystyrene, such as mechanical recycling and chemical recycling, that can convert polystyrene waste into new products or raw materials.

In general, polypropylene is more recyclable than polystyrene

4. Conclusion

In summary, while polystyrene vs polypropylene have their strengths, polypropylene offers superior overall strength and durability. By understanding their properties and evaluating your application requirements, you can make an informed choice that ensures optimal performance and longevity.

Are you looking for a variety of PP plastic products? EuroPlas and its experienced professional staff are committed to providing customers with high quality products and services. Please visit here to learn more: PP Search - EuroPlas - The world's No1 filler masterbatch manufacturer.

Thank you for considering EuroPlas as your plastic solutions partner of choice. Our professional team is ready to offer experienced guidance and support to meet your specific needs. If you have any questions about our goods, require customized solutions, or want to work on sustainable initiatives, please contact us right away!