PVA vs. PHA Plastic: What Are The Differences?

PVA and PHA plastic have gained significant attention from manufacturers due to their properties and biodegradation levels. However, there are differences between these two materials that businesses should know when pursuing affordable and eco-friendly manufacturing.

Let’s scroll down for more information!

Read more: What is PHA bioplastic? The pros and cons of PHA bioplastic

1. Overview of PHA Plastic

PHA plastic or Polyhydroxyalkanoate is created by microorganisms—often genetically modified—that synthesize plastic from organic sources. These microbes store PHA as carbon reserves, which they use to grow and reproduce.

PHA plastic or Polyhydroxyalkanoate is created by microorganisms—often genetically modified—that synthesize plastic from organic sources. These microbes store PHA as carbon reserves, which they use to grow and reproduce.

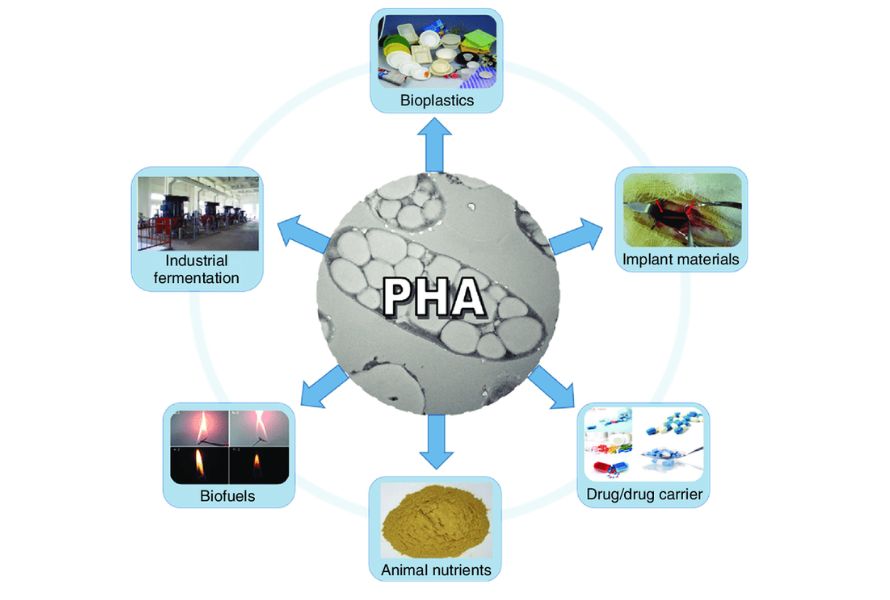

PHA plastic is used in medical applications such as sutures, slings, bone plates, and skin substitutes. Its chemical structure is comparable to that of conventional polymers. Another application of PHA in the commercial sector includes single-use food packaging.

2. What is PVA Plastic?

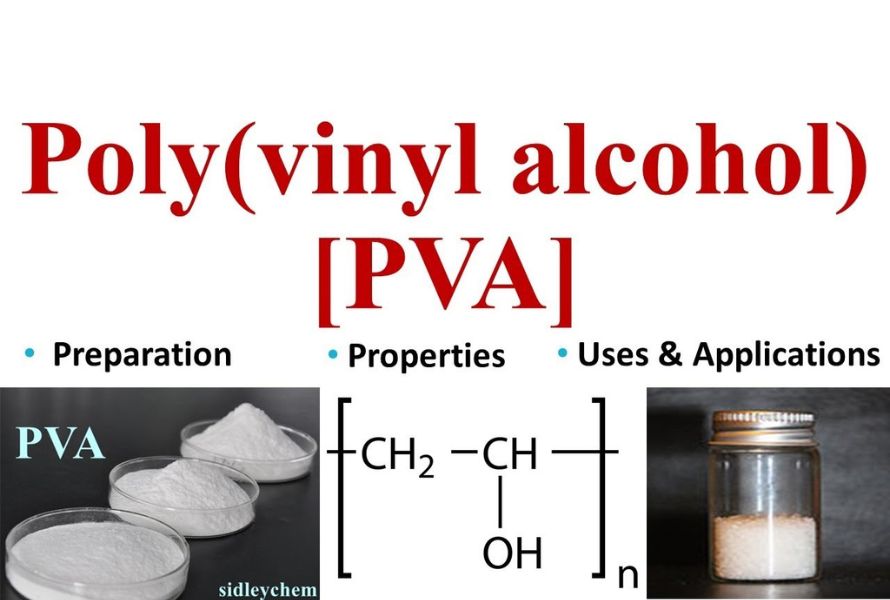

Polyvinyl alcohol (PVA) is a water-soluble synthetic polymer created when polyvinyl acetate partially hydrolyzes. It is odorless, colorless, and solid. PVA is a well-liked option for coatings and packaging films because of its outstanding film-forming qualities. Its wide range of application sectors includes packaging, paper, textiles, adhesives, and coatings.

Polyvinyl alcohol (PVA) is a water-soluble synthetic polymer created when polyvinyl acetate partially hydrolyzes. It is odorless, colorless, and solid. PVA is a well-liked option for coatings and packaging films because of its outstanding film-forming qualities. Its wide range of application sectors includes packaging, paper, textiles, adhesives, and coatings.

3. Are PVA And PHA The Same? What Are The Differences?

PVA and PHA plastic are not the same since they feature distinct chemical structures, properties and applications.

Polyvinyl alcohol (PVA) is a linear polymer formed from vinyl acetate, while PHA plastic is bio-polyester generated by microorganisms with a more complex structure incorporating hydroxy alkanoate groups.

Water-soluble PVA can biodegrade. However, the study shows that certain conditioners are required for full biodegradation. It requires the presence of particular bacteria and enzymes and a certain amount of time in the effluent water treatment plant. Thus, properly managed recycling and controlled disposal are needed to reduce the impact of PVA on the environment.

Meanwhile, PHA plastic can limit the buildup of plastic trash and its detrimental impact on ecosystems because it’s biodegradable in various environments, including soil, sea, and compost settings.

PVA is a relatively inexpensive raw material for manufacturing that comes in a variety of forms, including sheets, films, fibers, and powders. It facilitates simple equipment cleaning and maintenance, lowers waste output, opens new manufacturing processes, and saves time, resources, and energy. All of these factors contribute to increased manufacturing efficiency for businesses.

PVA material has high gas barrier qualities, is resistant to UV rays and chemical exposure, and is as durable as other materials. It is beneficial in packing due to its tensile strength and elongation at break.

PHA plastic has a number of advantages for the environment and economy, such as biodegradability, renewable resource availability, and a lower carbon footprint. The material is a sustainable substitute for plastics derived from petroleum since they can decompose in a variety of settings. It also has strong barrier qualities and thermal stability.

PHA plastic can be made from various feedstocks, including waste products and agricultural byproducts, which lowers manufacturing costs and improves economic feasibility. It can also be processed using standard plastic manufacturing equipment, making it easier to integrate the material into current production lines without requiring major changes.

Thanks to its special qualities and versatility, PVA material is an excellent choice for various sectors. Common applications include packaging films, coatings, adhesives, and textiles. Its 3D printing process allows designers to create intricate designs, while its textile industry uses it for fibers and films. Its water solubility offers new uses in ecologically friendly packaging, and its anti-static qualities make it appropriate for the manufacture of semiconductors and electronics.

Meanwhile, PHA plastic is adaptable and can be used in various applications, including consumer goods, packaging (bags, containers, and food packaging), and agricultural films. It’s safe for use in medical applications like wound dressings and sutures. Due to its non-toxic properties, it’s perfect for applications on the human body, such as catheters, syringes, surgical instruments, etc.

4. Conclusion

Though boasting different chemical structures and levels of biodegradability, PVA and PHA plastic are two useful materials in various industries. Understanding their differences will help businesses decide what material is more suitable for their products and encourage ecologically conscious methods in product development.

5. About EuroPlas

As a professional in the masterbatch industry, EuroPlas understands the demand for biodegradable plastic for sustainable development and the environment. Therefore, we've developed Bioplastic Compounds and Bio Fillers.

- BioNEXT is a bio compound that can be decomposable within a year after use. Our products are environment-friendly and possess many outstanding features. We've made it through strict quality control management to meet all the requirements.

- Bio Filler from EuroPlas is a cost-effective material solution for bioplastic products. It's a biodegradable material that improves several properties of end-products, such as stiffness, gloss, etc. It can act as an anti-block and slipping agent in blown film.