With growing concerns over plastic pollution and climate change, the global search for greener materials has intensified. One of the more innovative developments in this space is sweet potato as bioplastic—a material derived from the starch-rich tuber with the potential to replace conventional plastics. But how sustainable is it really?

This article explores the viability of sweet potato as a bioplastic source, comparing its environmental impact, performance, and production potential.

Read more: Potato starch bioplastic pros and cons

1. What Is Sweet Potato Bioplastic?

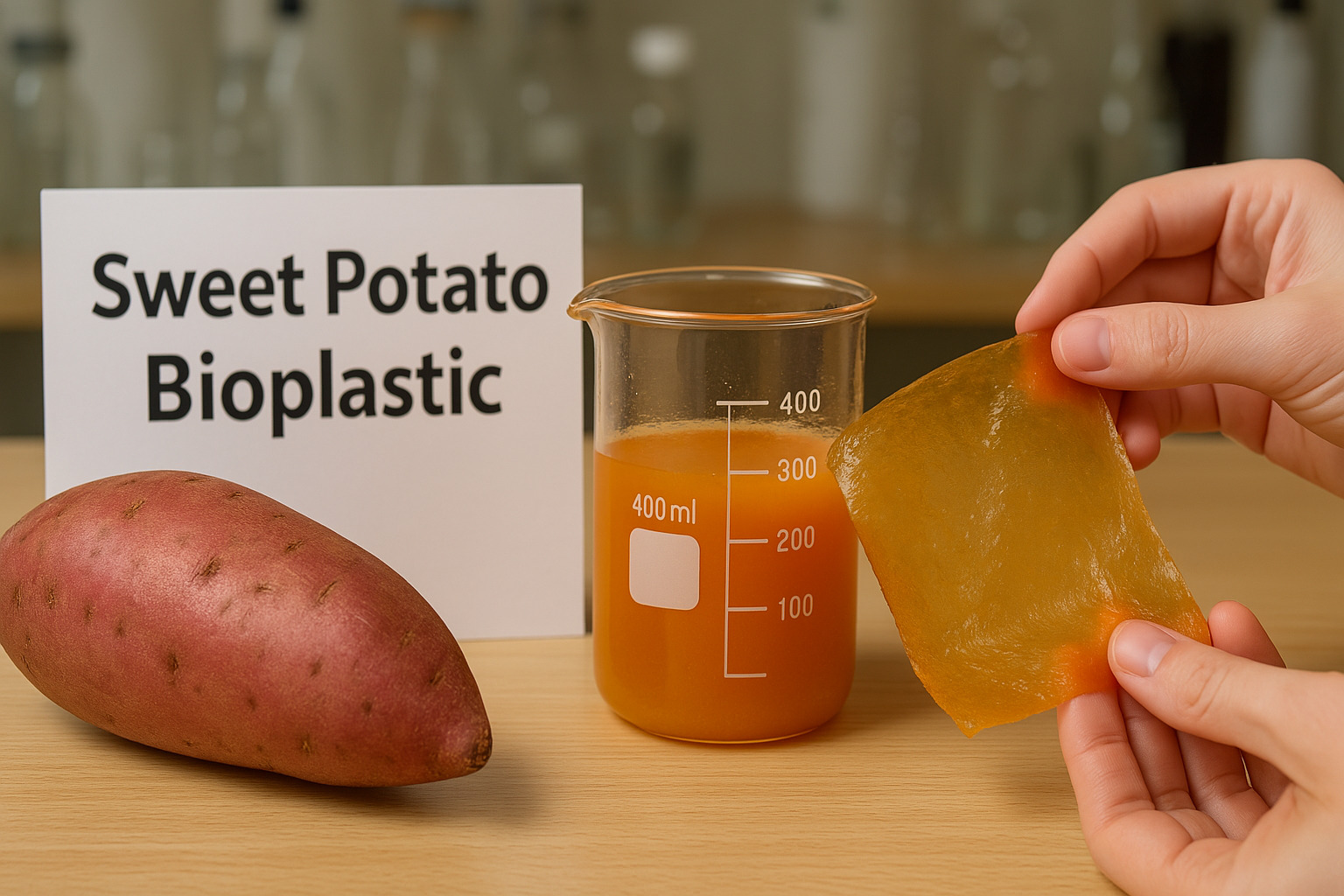

Bioplastics are plastics made from renewable biomass sources. In the case of sweet potato, its high starch content can be extracted, converted into glucose, and then fermented into lactic acid to produce PLA (polylactic acid), or processed directly into thermoplastic starch (TPS).

Sweet potato-based bioplastic can be molded into films, packaging materials, disposable utensils, and agricultural sheets.

What Is Sweet Potato Bioplastic?

2. Environmental Benefits

2.1. Renewable and Fast-Growing Source

Sweet potatoes grow quickly and thrive in diverse climates. Unlike crops such as corn, they require less water, fewer pesticides, and can grow in poor soil conditions.

2.2. Lower Carbon Footprint

Producing sweet potato as bioplastic generates significantly fewer greenhouse gases compared to petroleum-based plastics. The crop absorbs CO2 during its growth, offsetting emissions during processing.

2.3. Biodegradability

Depending on formulation, sweet potato bioplastics can biodegrade in soil or composting environments faster than traditional plastics, reducing landfill burden.

3. Comparison with Other Bioplastic Sources

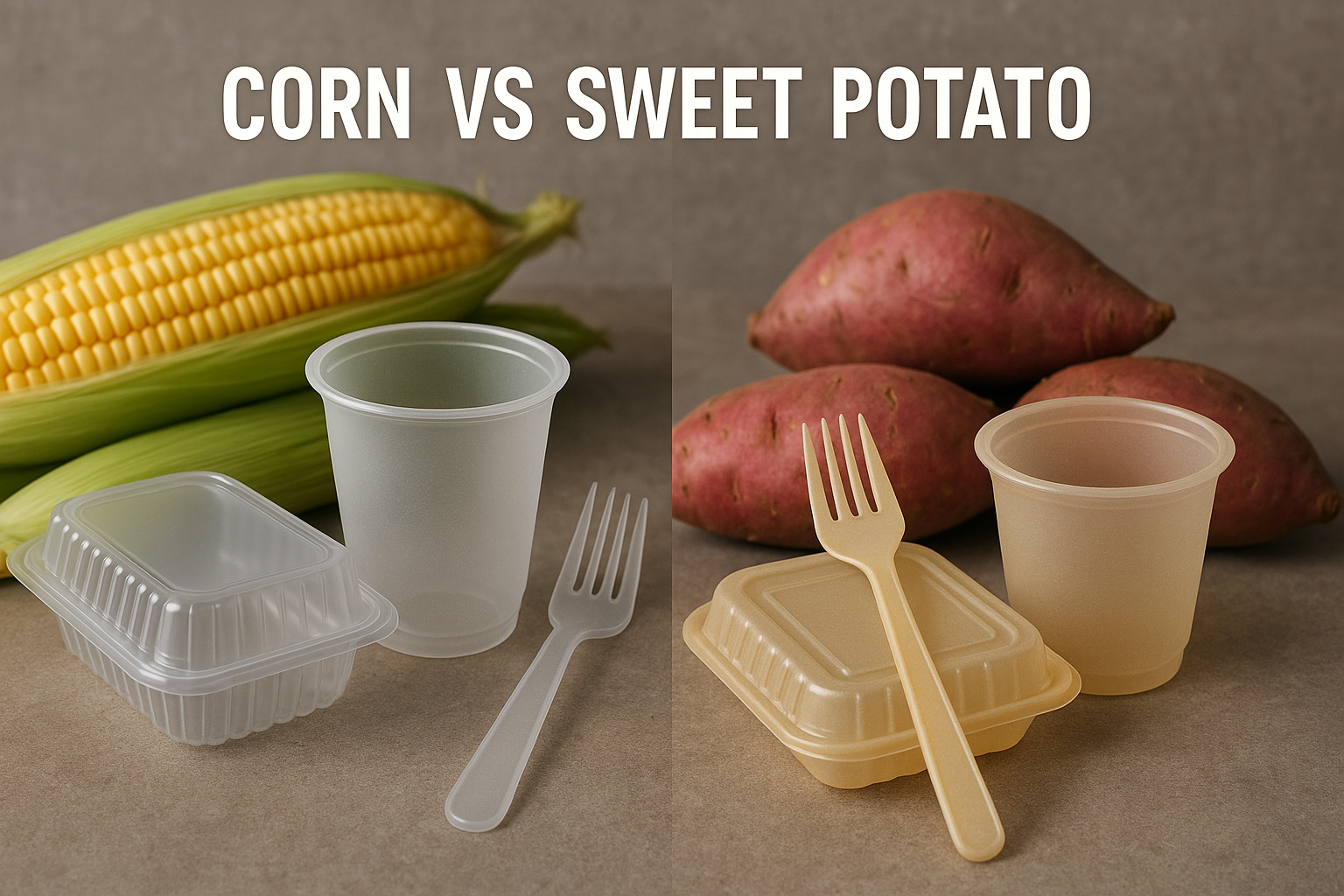

3.1. Corn vs. Sweet Potato

While corn-based PLA dominates the bioplastic market, it requires intensive farming and may compete with food resources. Sweet potato, especially non-edible or surplus varieties, offers a less food-competitive alternative.

Corn vs. Sweet Potato as Bioplastic

3.2. Sugarcane vs. Sweet Potato

Sugarcane also produces bioethanol and bioplastics, but its cultivation is water- and labor-intensive. Sweet potatoes offer a shorter growth cycle and less environmental impact.

Sugarcane also produces bioethanol and bioplastics, but its cultivation is water- and labor-intensive.

4. Challenges to Adoption

Despite its promising environmental benefits, the adoption of sweet potato as bioplastic still faces several key obstacles. One of the primary barriers is the lack of industrial-scale infrastructure for processing sweet potato into bioplastic. In contrast to corn PLA, which benefits from an established global supply chain, the production of sweet potato-based bioplastic remains in its infancy, requiring substantial investment and technical development.

Another challenge lies in the regional availability of sweet potato. Although it is widely grown in parts of Asia and Africa, sweet potatoes are not yet cultivated at the industrial level across all regions, which limits the scalability of production. Ensuring a reliable and consistent supply of raw material is essential for widespread adoption.

In terms of performance, sweet potato bioplastics—especially in the form of thermoplastic starch—face challenges such as lower moisture resistance and mechanical strength compared to conventional plastics. These limitations must be addressed through material engineering, such as polymer blending and additive incorporation, to meet the demands of various industrial applications.

5. Use Cases and Applications

Sweet potato bioplastic has the potential to serve diverse industries, particularly in the context of reducing single-use plastics. In packaging, it can be used to produce compostable films and wraps that offer an environmentally friendly alternative to conventional plastic packaging. These products are particularly well-suited for food packaging where biodegradability is valued.

In the consumer goods sector, sweet potato-based bioplastics can be molded into disposable items such as plates, straws, and cutlery. These applications not only support waste reduction but also align with increasing regulations on plastic bans worldwide.

The agricultural sector also benefits from sweet potato bioplastics, which can be used in mulch films and seedling trays. These products naturally decompose after use, eliminating the need for collection and disposal. Furthermore, emerging research is exploring the potential for using sweet potato PLA in 3D printing, presenting new opportunities for sustainable innovation.

6. Research and Development

Ongoing research and development efforts are critical to enhancing the performance and viability of sweet potato as bioplastic. Countries like Japan, Vietnam, and China are investing in scientific studies that seek to optimize the processing of sweet potato starch into more durable and versatile plastic materials.

These studies are addressing key performance issues, including tensile strength, moisture resistance, and flexibility. Researchers are also working on improving the efficiency of fermentation and polymerization processes. Collaborative initiatives between universities, research institutions, and green technology startups are accelerating the development of commercial solutions.

Such innovation is essential for overcoming the technical challenges currently limiting the widespread use of sweet potato bioplastic and for positioning it as a viable alternative in the bioplastics market.

Ongoing research and development efforts are critical to enhancing the performance and viability of sweet potato as bioplastic.

7. Future Outlook

Looking ahead, sweet potato as bioplastic holds immense potential, especially in regions with strong agricultural bases and favorable climate conditions. With adequate support, it could become a regionally sourced material that reduces dependency on fossil fuels and addresses plastic waste issues at the local level.

To unlock its full potential, however, governments and industries must collaborate to build necessary infrastructure, standardize quality controls, and provide financial incentives. Policy support—such as subsidies for sustainable materials or regulations on conventional plastics—could play a decisive role in promoting adoption.

As consumer demand for eco-friendly products continues to grow, and technological advancements drive down production costs, sweet potato bioplastics may transition from an experimental material to a mainstream component of the circular economy.

These applications align with global goals of reducing single-use plastics and promoting circular economy practices:

- Packaging Films: Compostable wraps and bags

- Disposable Items: Plates, cutlery, straws

- Agriculture: Mulch films and seedling trays

- 3D Printing: Emerging use of sweet potato PLA filaments

8. Conclusion

Sweet potato as bioplastic holds significant potential to become a truly sustainable material. It offers renewable sourcing, faster biodegradability, and lower environmental impact compared to fossil-based plastics and some current bioplastics.

However, to move from lab innovation to mainstream adoption, it requires infrastructure development, continued research, and industry investment. With proper support, sweet potato could help lead the future of bioplastics—rooted in sustainability.

9. About EuroPlas

EuroPlas is a trusted global plastic manufacturer with 7 factories located in Vietnam and Egypt. With a total annual capacity of 0.8 million tons, EuroPlas delivers high-quality plastic solutions to customers in more than 95 countries worldwide. The company’s portfolio includes 6 key product lines: filler masterbatch, color masterbatch, plastic additives, engineering plastic compounds, bioplastics, and biofillers.

In the bioplastics field, EuroPlas proudly introduces its BiONext series—an advanced bioplastic product line developed to support sustainability goals. BiONext bioplastic (shortened of biodegradable plastic) compounds are made from renewable sources such as polylactic acid (PLA) and Polyhydroxyalkanoate (PHA), plants (corn, palm oil, potatoes) or fossil fuels such as aliphatic-aromatic co-polyester (PBAT). With outstanding advantages, BiONext bioplastic compound is widely used in various fields. Common applications of bioplastic are making bioplastic packaging, blowing food wrap, biodegradable shopping bags, agricultural mulch films, lamination, food containers, disposable bowls, chopsticks, cups, spoons, forks,...

If you wish to learn more about BiONext, contact us for more information: https://europlas.com.vn