White masterbatch is a common example of masterbatch additives, which are used to give plastic polymers additional colors and characteristics. The additive is essential in giving plastic goods these qualities since it is simple to use, provides high-quality final products, has great dispersion, and performs exceptionally well in terms of color. Moreover, it is safe for use in food packaging. Thanks to its outstanding features, white color masterbatch is widely used in diverse industries. Let’s dive into the details to know more about this material!

1. Brief definition of white masterbatch

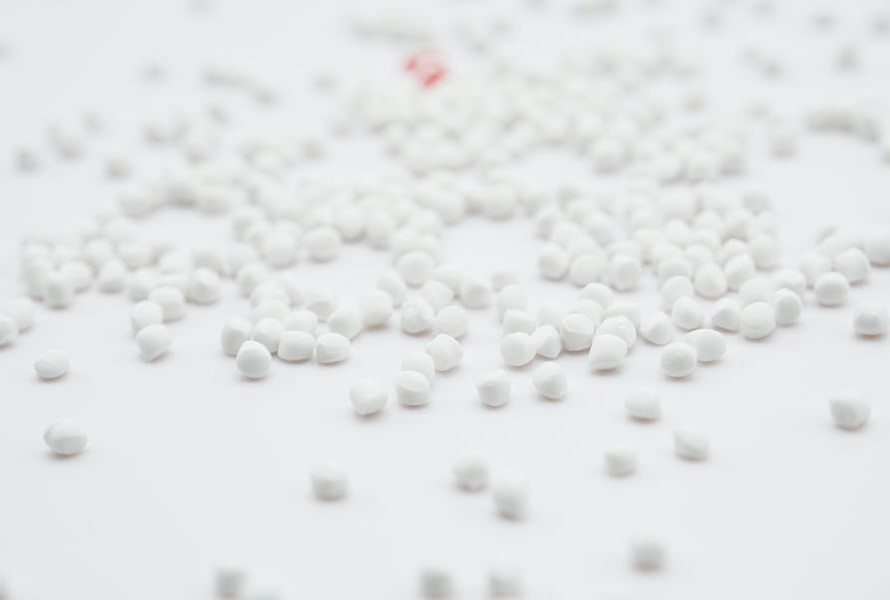

White masterbatch is a type of plastic additive that gives plastic items a vivid white hue. During the production process, a carrier resin and a mixture of titanium dioxide are added to the basic polymer. Since the light is scattered by the TiO2 particles, it provides the material with a white appearance and improved opacity. White color masterbatch is inexpensive and adaptable and is used in pipes, sheets, films, and packaging materials. It is an essential tool in the plastics sector because it can be tailored to satisfy specific requirements for brightness, opacity, and other qualities.

2. Advantages of White Masterbatch

2.1. Enhances opacity and brightness

The capacity of white masterbatch to give plastic goods outstanding opacity and whiteness is one of its main advantages. White color masterbatch gives the base polymer a uniform and constant white hue by adding premium titanium dioxide (TiO2) and other additives. Applications like packaging materials and consumer goods, where a pure, dazzling white look is sought, would particularly benefit from this.

2.2. Improves color consistency in final products

The uniform color distribution is important to all plastic products. By precisely dosing and dispersing white masterbatch in the base polymer, manufacturers can easily remove the possibility of color changes during the manufacturing process.

2.3. Cost-effective coloring solution

Using white masterbatch is a cost-effective method for achieving white color in plastics. Manufacturers can cut expenses and wasteful inventory by employing masterbatches instead of keeping different white pigments in their stores.

2.4. Facilitates customization and versatility

One of the reasons making white color masterbatch popular across industries is its versatility. It can be customized to meet different requirements of the final products. For example, the material can be formulated with the UV protection attribute to protect the plastic items from UV rays. Since the underlying plastic is protected from damaging UV rays by the titanium dioxide particles in the masterbatch, which both scatter and absorb UV energy, white masterbatch is an ideal option for outdoor applications where UV degradation can cause color fading and shorten the life of the product.

3. Applications Across Industries

3.1. Plastic Manufacturing

It’s not difficult to see white plastic items everywhere around us, ranging from small toys to huge plastic sheets. Let’s take the toy sector for example. Many building blacks, action figures, and dolls have a cheery and eye-catching appearance, thanks to the contribution of white masterbatch.

3.2. Packaging Industry

Plastic bags, containers, films, and other packaging materials are good examples of white color masterbatch in the packaging sector. It is used to provide a white color, giving the package a tidy and appealing appearance.

3.3. Textile Industry

The production of fiber and non-woven materials requires a complex process that calls for certain raw ingredients with a high dispersion quality. The grades of the white masterbatch are specifically designed with regard to heat stabilization, TiO2, and carrier resin for specific uses.

3.4. Construction Sector

You can find white color masterbatch in a variety of building and construction sector’s products, such as roofing sheets, pipes, and fittings. The material helps provide these products with a consistent and appealing look.

4. Conclusion

In short, white masterbatch offers several benefits, including easy to use, maintaining chemical stability, environmentally friendly, and suitable for food items. Its high quality allows for efficient application in blow molding and injection, producing well-finished final products with improved whiteness and glossy features. It also offers excellent pigmentation and efficient final products, making it a valuable choice for various industries.

5. An introduction of white masterbatch from EuroPlas

If you are looking for an authentic and reliable white masterbatch supplier, go for EuroPlas. As a world leader in the masterbatch field, we have the high-quality material to meet all your needs.

Our white color masterbatch is a concentrated color granule made from Titanium Oxide (TiO2), carrier resins, and additives. It provides a perfect white color and excellent dispersion, heat resistance, and thermal stability. TiO2 effectively scatters light, improving lightness and brightness. It also absorbs UV light, enhancing durability during weather conditions. Our masterbatch has excellent mechanical properties, allowing it to withstand impacts and tear resistance. The material is available in various types, including PP, PE, PS, ABS, and polyester, and is widely used in various fields like blow molding, injection molding, and high-end rotational molding.

Don’t hesitate to contact EuroPlas right now for the best product deals!