The demand for conductive plastics has significantly increased in modern industries, especially in electronics, automotive, and industrial applications. Conductive plastics provide lightweight, corrosion-resistant, and cost-effective alternatives to metals, making them highly valuable across various sectors. Among the key additives used to achieve electrical conductivity in plastics, carbon black is one of the most effective and widely utilized materials. This article will explore the importance of conductivity in plastics, how carbon black enhances these properties, and its applications.

1. Importance of Conductivity in Plastics

Plastics are widely recognized for their versatility and durability, making them essential in many industries. However, traditional plastics lack electrical conductivity, which restricts their use in electronic applications. As technology continues to evolve, the demand for materials that combine the mechanical advantages of plastics with electrical conductivity has become more important.

- Enhancing Safety and Performance: Conductive plastics play a critical role in mitigating static electricity, which can cause significant damage to sensitive electronic components. By dissipating static charges, these materials enhance the safety and performance of electronic devices, making them indispensable in the manufacturing of electronic components and packaging.

- Applications in Modern Technology: Conductive plastics are used in a variety of applications, including anti-static packaging materials and electromagnetic interference (EMI) shielding. They are crucial in the automotive industry for sensors and switches, in consumer electronics for housings and enclosures, and in the medical field for devices that require reliable conductivity.

Conductive Plastics

Conductive Plastics

2. How Carbon Black Improves Conductivity

Carbon black is a fine, black powder primarily composed of elemental carbon, known for its excellent electrical conductivity and thermal stability. When added to plastic, it enhances the material’s electrical conductivity and provides other functional benefits. Here's how carbon black achieves this:

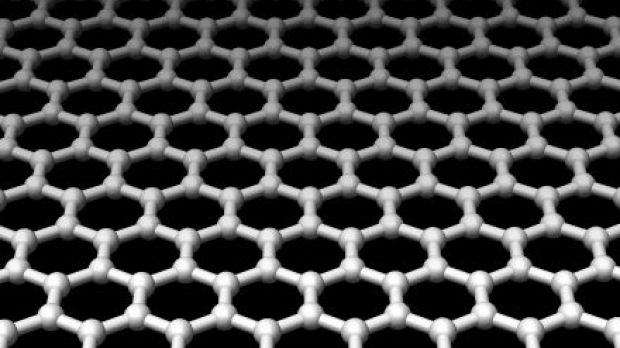

2.1. Formation of Conductive Networks

Carbon black particles are dispersed throughout the plastic matrix. At a certain concentration (known as the percolation threshold), the particles form a network of interconnected conductive pathways, enabling the flow of electrons through the material.

Carbon Black

2.2. Particle Properties

The effectiveness of carbon black in enhancing conductivity depends on several factors, including particle size, structure, and surface area. Smaller carbon black particles with a high surface area and a more interconnected structure are more effective at forming conductive networks. This means that optimizing these properties can significantly influence the overall conductivity of the material.

2.3. Electron Mobility

One of the key attributes of carbon black is its high density of free electrons. These free electrons allow carbon black to conduct electricity efficiently. When carbon black is embedded in a polymer, these free electrons transfer electrical charges across the material, facilitating conductivity. This property is particularly important in applications where efficient electrical conduction is required.

Electron Mobility

2.4. Adjusting Conductivity

Manufacturers have the ability to tailor the conductivity of plastics by controlling the concentration of carbon black. This flexibility allows for the creation of materials with varying levels of conductivity, ranging from antistatic materials to fully conductive plastics. By adjusting the amount of carbon black, manufacturers can meet the specific requirements of different applications.

2.5. Synergistic Effects

Improved Thermal Conductivity: Along with electrical conductivity, carbon black enhances thermal conductivity, helping dissipate heat in electronic components or other heat-sensitive applications.

Strength and Durability: The addition of carbon black improves the mechanical properties of plastic, including strength and resistance to wear and degradation.

3. Applications of Conductive Plastics with Carbon Black

- Electronics and Semiconductors: Used in components like housings and connectors to prevent static buildup or as shielding against electromagnetic interference (EMI).

- Automotive Industry: Found in fuel system components and sensors requiring static dissipation or conductivity.

- Energy Storage: Used in battery casings and components of lithium-ion batteries.

Packaging: Conductive plastic packaging protects sensitive electronic equipment during storage or transport by preventing static charge accumulation.

Using Carbon Black in Conductive Plastics

4. Conclusion

Carbon black plays a crucial role in enhancing the electrical properties of conductive plastics, making them essential across various industries. By forming a conductive network within the polymer matrix, carbon black transforms standard plastics into materials that can effectively dissipate electrostatic charges, shield against electromagnetic interference (EMI), and improve thermal conductivity. Its cost-effectiveness, durability, and versatility make it a preferred choice for manufacturers seeking to develop high-performance conductive solutions. As industries increasingly demand lightweight, corrosion-resistant, and electrically conductive materials, the use of carbon black in conductive plastics will continue to be a key factor in driving innovation and efficiency.

5. About EuroPlas

EuroPlas stands as a prominent global leader in the field of plastic masterbatch manufacturing. Renowned for its unwavering commitment to innovation, quality, and sustainability, EuroPlas provides an extensive array of high-performance masterbatch solutions including: bioplastic compounds, color masterbatch, plastic additives, engineering plastic compounds, filler masterbatch and bio filler. Each product is designed to improve the durability, flexibility, and functionality of plastic products, catering to a wide range of industries such as packaging, automotive, construction, and consumer goods.

EuroPlas’s masterbatch

Utilizing cutting-edge manufacturing technologies and stringent quality control processes, EuroPlas ensures that its solutions meet global industry standards.

By prioritizing customer needs and fostering long-term partnerships, the company has established itself as a trusted supplier worldwide. EuroPlas continues to drive innovation in the plastics industry, offering sustainable and cost-effective solutions tailored to meet the evolving demands of manufacturers.

For more information and samples, please contact us HERE!