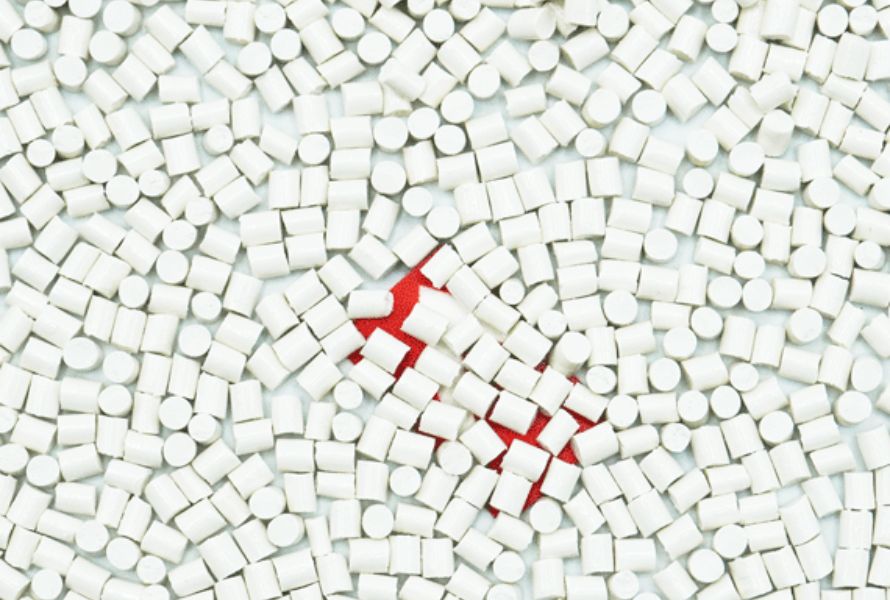

Acrylonitrile Butadiene Styrene (ABS) resin is a high-performance thermoplastic polymer that combines strength, toughness, and aesthetic versatility. Its popularity stems from its ability to balance rigidity and impact resistance with ease of processing, making it a go-to material in various industries. This article explores the top industries that rely heavily on ABS resin, illustrating why it's such a crucial component of modern manufacturing.

Read more: ABS plastic - Everything you need to know

This article explores the top industries that rely heavily on ABS resin

1. Automotive industry

In the automotive sector, ABS resin has become indispensable thanks to its ability to withstand physical impacts while maintaining structural integrity. Automakers use ABS in dashboards, door panels, seat backs, pillar trim, center consoles, and exterior body parts such as mirror housings and grilles.

Its light weight helps reduce the overall mass of vehicles, thereby enhancing fuel efficiency and enabling compliance with increasingly stringent environmental standards. ABS’s excellent surface finish and paintability allow for both functional and decorative applications, meeting the dual needs of performance and consumer aesthetics.

Leading brands like Ford and Toyota incorporate ABS into interior and under-the-hood components, especially where vibration damping, thermal resistance, and visual appeal are critical.

2. Consumer electronics

ABS resin’s combination of insulating properties, dimensional stability, and design flexibility has made it the preferred material for electronics housings. Devices such as televisions, laptops, remote controls, mobile phones, and smart home devices often use ABS to protect internal components from impact and thermal stress.

The resin’s smooth surface and high gloss levels support branding and custom textures. Its flame retardant capabilities (when formulated accordingly) make ABS particularly suitable for electronic devices requiring compliance with safety regulations. Tech giants like Samsung and HP have long favored ABS in casing production due to these attributes.

3. Home appliances

From kitchen gadgets to large white goods, ABS resin is a fixture in home appliance design. Its chemical resistance makes it ideal for applications exposed to cleaning agents, moisture, and fluctuating temperatures.

Washing machine panels, vacuum cleaner housings, refrigerator liners, and air conditioner parts are frequently molded from ABS. The resin enables the creation of robust yet sleek components that stand up to daily wear while maintaining an attractive appearance. Brands such as LG and Bosch rely on ABS to balance aesthetics with long-lasting functionality.

4. Toys and recreation

Toys are among the most recognizable products made from ABS resin. The material’s toughness and safety make it ideal for toys that are handled roughly or thrown around. Lego bricks, perhaps the most iconic ABS product, showcase the material’s dimensional precision, color vibrancy, and impact resistance.

Beyond building blocks, ABS is used in action figures, educational tools, and even sports equipment components. The resin can be safely colored, molded into complex shapes, and complies with safety regulations in most global markets—making it a staple of the toy industry.

Toys are among the most recognizable products made from ABS resin.

5. Construction and piping systems

Although not always visible, ABS plays a vital role in construction. In piping systems, ABS is preferred over other plastics for venting, drainage, and waste systems, particularly in colder environments where its low-temperature impact resistance excels.

ABS piping resists corrosion and scale buildup, making it ideal for long-term installations. Contractors appreciate its ease of installation—lightweight yet rigid, easy to cut and solvent weld. Builders also use ABS sheets and profiles for wall panels, trim, and light-duty structural components in both commercial and residential applications.

6. Medical devices

In the medical sector, ABS resin is employed for non-invasive instruments, device housings, and disposable components that demand sterility, biocompatibility, and reliable mechanical properties. ABS is used in inhalers, infusion pumps, diagnostic kits, and sample transport containers.

Medical-grade ABS ensures dimensional accuracy and the ability to withstand chemical exposure from disinfectants. It can be gamma sterilized or treated with ethylene oxide depending on application needs, and its cost-effectiveness makes it viable for high-volume production.

7. Luggage and travel gear

The demand for lightweight yet impact-resistant travel solutions has made ABS a favorite in the luggage industry. Hard-shell suitcases and protective gear cases made from ABS offer durability without sacrificing portability.

ABS’s rigidity protects contents from physical stress during travel, and it can be textured or colored to meet consumer design preferences. It’s also more affordable than polycarbonate while offering sufficient performance for most travel needs. Many budget and mid-range luggage brands use ABS as a standard material for their product lines.

8. 3D printing and prototyping

In rapid prototyping and low-volume production, ABS resin is widely used in Fused Deposition Modeling (FDM) 3D printing. Engineers, designers, and hobbyists favor ABS for its balance of strength, machinability, and post-processing potential.

It supports sanding, painting, and gluing, which makes it suitable for mock-ups, functional prototypes, and even end-use parts. Though it requires a heated bed and enclosed build environment due to warping risks, ABS remains one of the most accessible and versatile filaments in the 3D printing landscape.

9. Conclusion

Across industries—from automotive to electronics, toys to tools—ABS resin has proven to be one of the most versatile and reliable polymers in manufacturing. Its adaptability, visual quality, and mechanical performance make it an ideal candidate for both technical and aesthetic applications.

As industries look toward sustainable design and recyclable thermoplastics, ABS continues to evolve with improved formulations and performance properties tailored to modern demands.

ABS resin has proven to be one of the most versatile and reliable polymers in manufacturing.

10. About EuroPlas ABS compound

EuroPlas, one of the world’s leading masterbatch and compound manufacturers, offers high-performance ABS compound solutions that cater to diverse industrial needs. With advanced formulation expertise, EuroPlas delivers ABS compounds that enhance impact resistance, dimensional stability, and surface finish—ideal for automotive interiors, appliance housings, consumer electronics, and more.

Produced in state-of-the-art facilities across Vietnam and Egypt, EuroPlas ABS compounds meet strict global standards while enabling cost-effective, reliable production for customers in over 95 countries. Currently, EuroPlas offers 3 ABS compounds:

Explore more about ABS compound offerings at europlas.com.vn.