Transparent plastic is one of the most popular plastic materials today. Transparent plastic can be made from many types of plastic such as HDPE, Polycarbonate, Polyetherimide, Polypropylene. Therefore, transparent plastic is not only diverse in design but can also inherit many characteristics from other plastic platforms. In this article, EuroPlas will introduce the Top popular transparent plastic materials.

1. Overview of the definition of transparent plastic

In particular, transparent plastics are classified into two main categories: thermoplastics and thermosetting plastics. The recognizable characteristics of this type of plastic are that it is transparent, colorless, odorless and receives light easily.

Transparent plastic is understood exactly as the properties of other plastic substrates. They are made through an injection molding process with necessary plastic additives. Almost any type of plastic substrate can be produced into transparent plastic such as: HDPE Plastic, Acrylic Plastic, PETG Plastic,...

Besides, transparent plastic also inherits the physical and mechanical characteristics of those plastic substrates. Therefore, transparent plastic possesses full heat resistance, stable impact resistance, high durability as well as can easily be cut or bent into molds to shape.

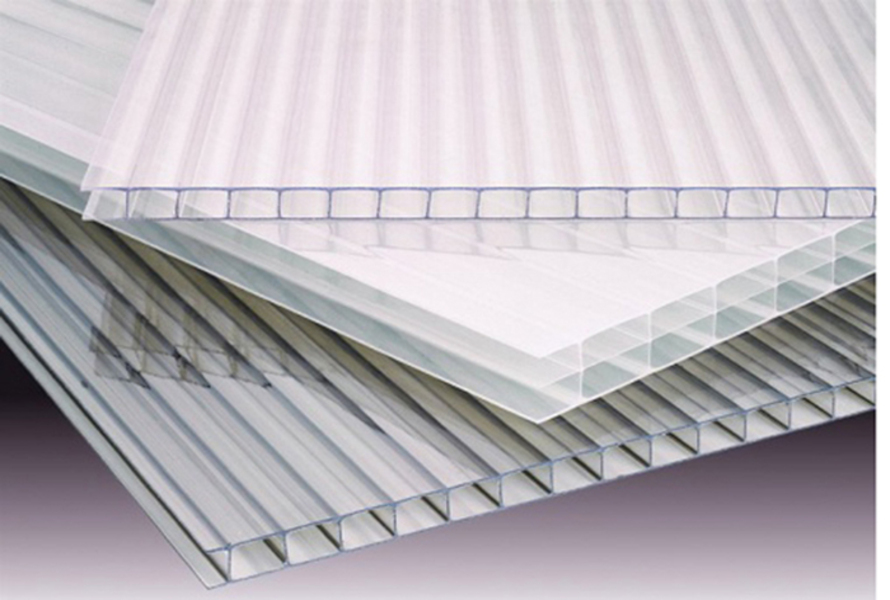

PVC transparent plastic sheet

2. Top popular transparent plastic materials

Transparent plastic is produced from a variety of plastic substrates with many different characteristics. Currently, there are 5-6 types of plastic materials that can be produced into transparent plastic. Let's consult EuroPlas now

2.1 Transparent plastic from Acrylic plastic

Acrylic plastic is produced mainly from the compound Acrylic Acid. Currently, Polymethyl methacrylate is the most popular Acrylic plastic on the market.

Acrylic plastic belongs to group 7 of the recyclable plastics because it is a material that is not easily recycled. Most of them will be used to create other useful items, so objects made from acrylic plastic will not crack or have any defects.

Acrylic plastic also possesses outstanding characteristics compared to other product lines:

- Acrylic plastic surface is considered flat and shiny. Therefore, Acrylic plastic easily combines with other colors and allows light to pass through easily

- The ability to resist water and mold is also an advantage of Acrylic plastic. Therefore, Acrylic plastic is commonly used in the furniture industry.

- Acrylic plastic is widely used in industries because of its high heat resistance and ease of shaping. Temperatures range from minus 30 degrees Fahrenheit to nearly 200 degrees Fahrenheit.

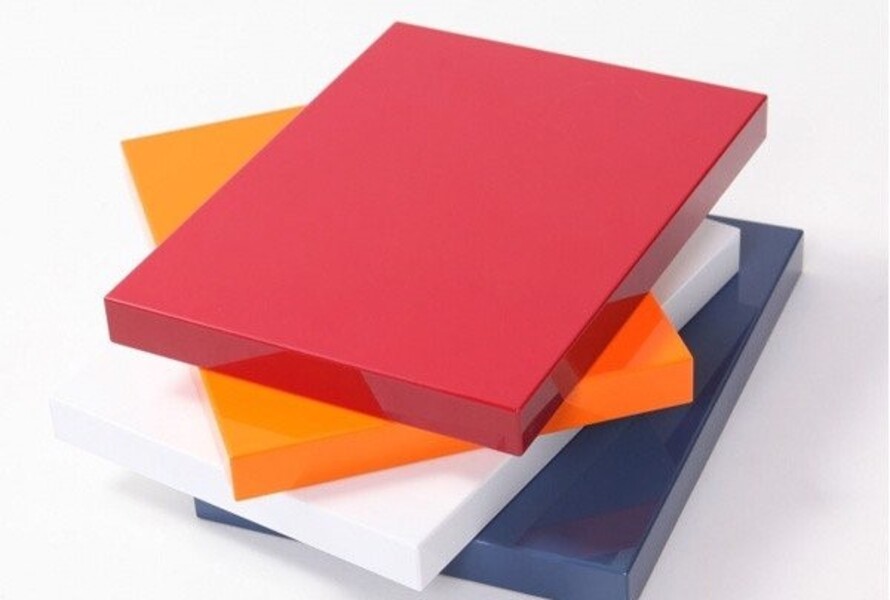

Acrylic plastic panels can be easily combined with color additives

2.2 Transparent plastic from HDPE plastic base

HDPE is classified as a thermoplastic resin refined from petroleum. The molecular density in the chemical structure of HDPE plastic is quite thick and forms a strong bond. Therefore, the surface of HDPE plastic is highly durable and able to withstand strong impacts.

HDPE plastic is considered the most popular material in the manufacturing industry. Besides, HDPE plastic also possesses abrasion resistance and resistance to strong chemicals. The main reason is because the molecular structure of HDPE plastic contains Ethylene linked together into long chains.

With the above properties, HDPE is used in many industries such as packaging, manufacturing plastic products, plastic corrugated iron, plastic pallets, water pipes, drainage systems, toys, packaging, tanks, exhaust pipes. ,...

In particular, HDPE plastic is very easy to mold and melt during the production process as well as shape the product. 142 degrees Celsius is the melting point of HDPE plastic, while 300 degrees Celsius is the decomposition temperature.

The light weight of HDPE plastics ranges from 0.93 to 0.97g/cm3, which allows their linear structure to have less branching and provide stronger intermolecular forces. Therefore, the tensile strength of HDPE plastic is also very impressive.

The positive environmental impact strengths of HDPE plastic are also highly appreciated by experts. The material is not too difficult to recycle and does not produce toxins that affect consumer health. This contributes to reducing up to 50% of plastic output discharged into the environment every year.

HDPE plastic is used in many industries

2.3 Transparent plastic from Polycarbonate plastic base

The chemical structure of Polycarbonate plastic is quite special because of the repeating carbonate group. These carbonate groups are derived from the reaction between bisphenol A (BPA) and phosgene. This synthesis results in the formation of a strong and durable polymer, called polycarbonate.

The basic properties of Polycarbonate plastic are formed from their density. The average density of Polycarbonate plastic ranges from 1.2g to 1.4 grams per cubic centimeter. They are classified as medium density plastics.

The melting point of Polycarbonate plastic fluctuates between 220 and 250 degrees Celsius. For Polycarbonate plastic to change from a hard state to a flexible state, the average temperature will be from 140 - 150 degrees Celsius. This is the appropriate temperature level for injection molding or shaping process.

In particular, the similarity between transparent plastic and Polycarbonate plastic is that polycarbonate plastic is a thermoplastic material derived from the chemical reaction between bisphenol A and phosgene. Both involve the compound Bisphenol A

The repetition of strong carbon bonds makes Polycarbonate plastic resistant to chemicals and minimizes surface abrasion.

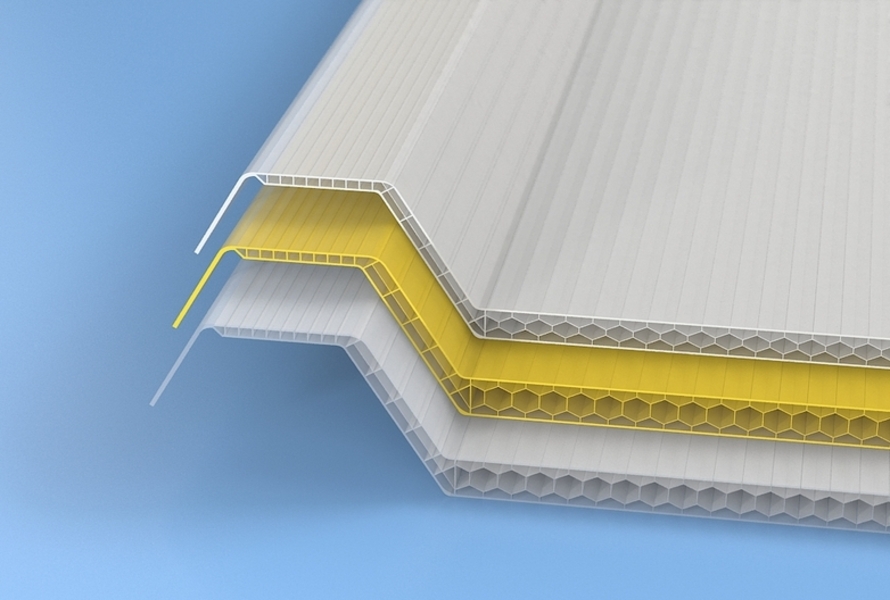

Polycarbonate plastic has high flexibility

Therefore, they are applied in the production of automobile components, medical equipment or electronic technology products.

Besides, Polycarbonate plastic is chosen to produce transparent plastic because it has high elasticity. The elastic modulus value of Polycarbonate plastic ranges from 2,000 to 2,400 megapascals (MPa).

This is the appropriate parameter level to help Polycarbonate Plastic have the ability to resist deformation when exposed to strong impacts.

2.4 Transparent plastic from Polyetherimide resin base

Polyetherimide plastic material is shaped in solid form. Polyetherimide resin possesses amber color and is transparent. Besides, when this type of plastic is not combined with any plastic additives, it is already fire resistant and stable.

The Oxygen density ratio of Polyetherimide resin is about 47%. Besides, the fire resistance level of the material meets UL94 - V - 0 standard. Ensinger's Polyetherimide resin production process in sheet and tree form uses Ultem® raw materials.

Polyetherimide plastic's ability to insulate and protect against UV radiation is comparable to other materials. They are also commonly used in the electronics technology industry.

In addition, Polyetherimide plastics are used in heavy industry because their heat resistance level is about 170 degrees Celsius for long periods of time. Like other plastics, Polyetherimide plastic also offers resistance to chemicals and strong acids. Therefore, anti-wear properties and reduced hydrolysis are also optimized.

Besides, its lightweight, durability, heat and chemical resistance make this material the preferred choice for various consumer products. It is used in home appliances, sports equipment, consumer electronics and other products where reliability and performance are important.

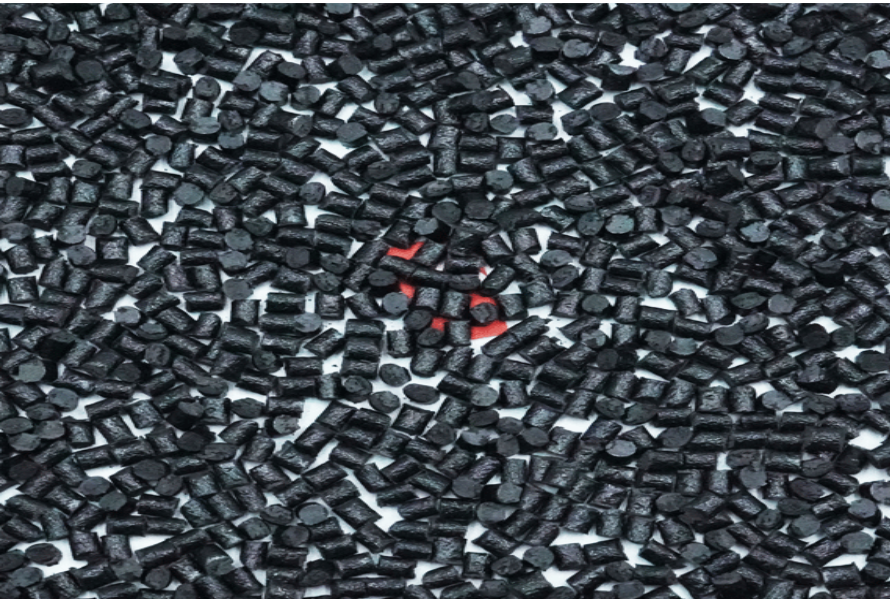

Polyetherimide plastic beads

3. Basic characteristics of transparent plastic

- High transparency: this is the most basic and easily identifiable characteristic of this type of plastic. This allows transparent plastic to be easily exposed to light without changing color. They are used to produce products with high transparency.

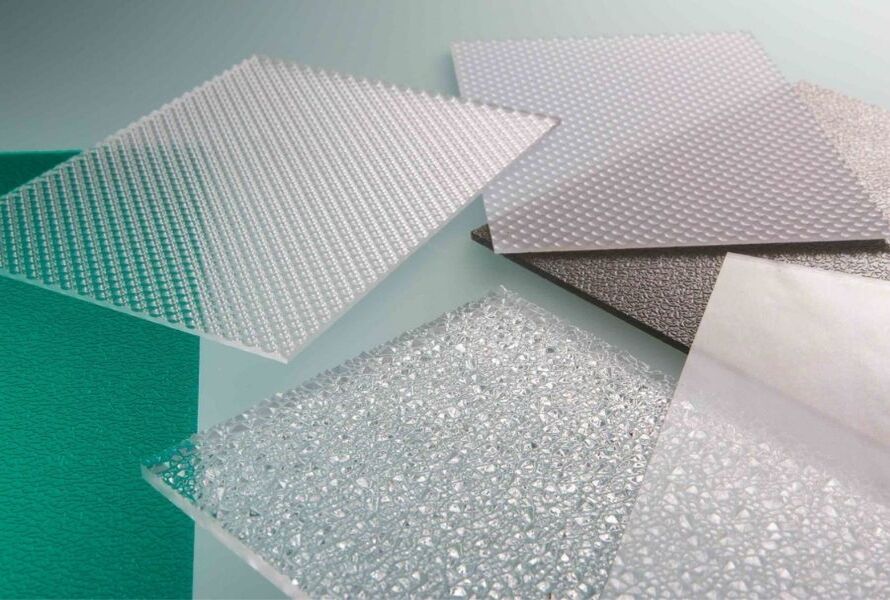

- UV resistance: Thanks to the surface's durable chemical structure and transparent properties, the plastic can resist UV rays for a long time without changing shape.

Transparent plastic has good durability

- Stable mechanical strength: The base resins that make up transparent plastic have quite high durability. They are capable of withstanding strong impacts for long periods of time with minimal damage or cracking. Therefore, the material is used in the production of protective glass, heavy industrial machinery covers,...

- Easy to mold: The flexibility of transparent plastic is very good. Besides, they can also be combined with many other additives or other materials during the production process to optimize performance.

- Safe for consumers' health: Transparent plastic is produced mainly from type 5 plastic. This is a plastic line that is safe for health, highly heat resistant and has no odor. Therefore, transparent plastic is also very environmentally friendly. Besides, you can also easily clean transparent plastic because they have a smooth and glossy surface.

Transparent plastic resists UV rays and allows light to pass through easily

Next, in terms of durability, if it comes to bearing capacity, transparent hard plastic panels will be the winning material, but if both are installed in an ideal environment, their durability is equal. lasts up to 20 to 30 years.

4. Introducing EuroPlas Polycarbonate technical plastic composite product

PC Flame Retardant and PC Glass Fiber compounds are one of the popular plastic material product lines at EuroPlas.

4.1 PC Flame Retardant Compound products

Based on customer and market needs, EuroPlas provides a variety of PC Flame Retardant products that meet international standards with UL94 fire resistance levels as follows: 5VA, 5VB, V0, V1, V2.

Safety standards during the production process and finished products delivered to consumers are carefully checked by the EuroPlas team through many stages. Halogen flame retardant will be mixed with Polycarbonate resin base.

PC Flame Retardant

EuroPlas is a company with rich experience in providing various engineering plastic compounds with excellent mechanical and thermal properties. In particular, EuroPlas' PC Compound Flame Retardant (PC -FR) adapts well to plastic additives and other materials, which improves work performance and increases product quality.

Our PC - FR material is used in many products such as: electrical sockets, electronic devices, device chargers,...

4.2 PC Glass Fiber Compound

EuroPlas is confident that the PC Glass Fiber Compound product line is one of the brand's products with the best durability, impact resistance and heat resistance.

Besides, EuroPlas' PC-GF product line can maintain stable size as well as demonstrate quite high optical clarity. Therefore, they are commonly used in many different industries.

PC Glass Fiber Compound

As we all know, fiberglass composition is the best plastic additive to improve the hardness of the structure to the surface of the material. Nearly all mechanical properties are significantly improved, but they still ensure the material's flexibility when exposed to temperature during injection molding.

The product line also fully meets the standards of censorship and serves the needs of the market and customers well. The above characteristics have helped PC - GF plastic become a popular material in the production of: cameras, printer ink, household electrical appliances (vacuum cleaners, electronic stoves, rice cookers), electronic devices (keyboard, power outlet, headphones,...)

The above article has provided you with the Top 4 popular transparent plastic materials. Please continue to follow EuroPlas Blog to update the latest news!