Understanding the various types of plastic is essential, particularly those that pose significant recycling challenges. This article explores the hard-to-recycle types of plastic and delves into the complexities that hinder their reprocessing. By examining these issues, we can foster a deeper awareness of the recycling landscape and its impact on ecological preservation.

1. Overview Of Hard-to-recycle Types Of Plastic

When discussing the types of plastic that cannot be recycled, it's essential to understand the underlying chemistry and structural properties that dictate their recyclability. Generally, plastics are categorized by their resin codes, with lower numbers indicating a higher likelihood of being recyclable.

This disparity in recyclability stems from the chemical composition of the plastics; thermoset plastics, for instance, are characterized by polymers that form irreversible chemical bonds, making them impossible to recycle. In contrast, thermoplastics can be re-melted and reshaped, presenting a more sustainable option.

When plastic is not recycled, it typically ends up in landfills, exacerbating the waste crisis. However, plastic waste can often be repurposed or reused, temporarily diverting it from landfills; for example, plastic bags can be used multiple times before disposal.

It's essential to explore alternatives to landfill disposal, viewing plastic waste as a valuable resource rather than worthless material. By promoting a culture of reuse and repurposing, we can reduce the environmental impact of plastic waste and move toward a more sustainable, circular economy.

2. Types Of Plastic That Is Hard To Recycle

Not all plastics are easy to recycle. Some types present significant challenges due to their chemical composition and properties. Here are the most common hard-to-recycle plastics:

2.1. Polyvinyl chloride (PVC)

Polyvinyl chloride (PVC) is the third most widely produced synthetic polymer globally, following polyethylene and polypropylene. Its rigid form is extensively utilized in construction for applications such as piping, doors, and windows, as well as in the production of bottles, non-food packaging, and various types of cards, including bank and magnetic cards.

PVC contains hazardous chemical additives, including phthalates, lead, cadmium, and organotins, which can pose health risks. These toxic additives may leach out or volatilize into the air over time, creating potential dangers, particularly for children. PVC is nearly impossible to recycle, which underscores the necessity to limit its use as much as possible. By recognizing the environmental implications of PVC and advocating for alternatives, we can contribute to a more sustainable future.

Read more: What is PVC Plastic? All Information About PVC Plastic

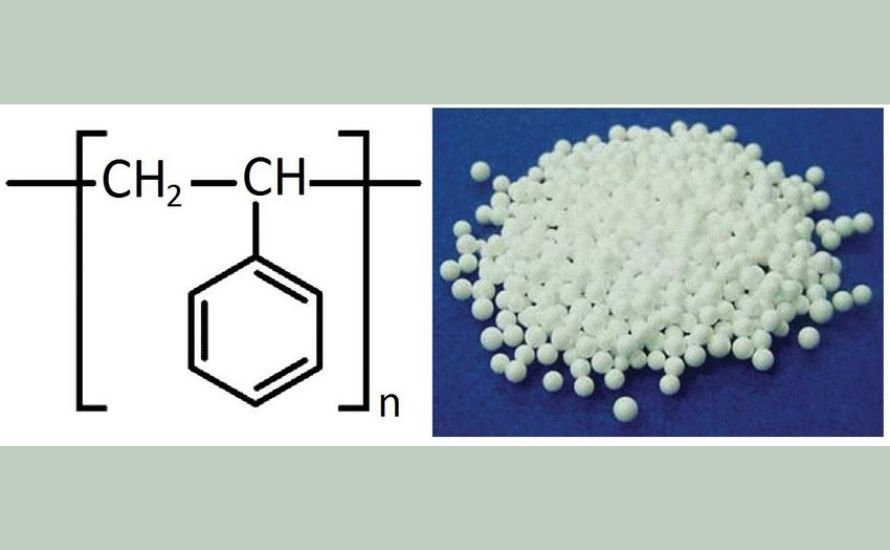

2.2. Polystyrene (PS)

Polystyrene (PS) is composed of numerous styrene units, which the International Agency for Research on Cancer classifies as a carcinogen. Exposure to styrene can irritate the skin, eyes, respiratory system, and gastrointestinal tract. Chronic exposure may lead to severe effects, including depression, headaches, fatigue, weakness, hearing loss, and impaired kidney function.

The production of polystyrene involves the use of hydrocarbons such as styrene and benzene. These substances are released into the atmosphere and react with nitrogen dioxide (NO₂) to form ground-level ozone, also known as tropospheric ozone or "bad" ozone, which is a dangerous air pollutant. Ground-level ozone can impair lung function and contribute to respiratory diseases.

PS is nearly impossible to recycle due to challenges in collection and high recycling costs. It does not biodegrade and is often incinerated for disposal. However, burning polystyrene releases styrene into the air and produces a mixture of toxic substances that can harm the nervous system. Therefore, minimizing the use of polystyrene is essential for environmental health.

Read more: Everything you need to know about polystyrene

2.3. Unsorted plastic (group 7)

Type 7 plastic, often referred to as "other" plastics, encompasses a variety of materials that do not fit into the standard categories of plastic. This type is commonly found in large water containers, jugs, baby bottles, and is notably used in industrial applications such as eyewear, phone casings, and DVDs.

However, Type 7 is considered the most hazardous among the various types of plastic due to its potential to leach bisphenol-A (BPA), a chemical linked to cancer and infertility, posing significant health risks. Consequently, it is crucial to avoid recycling or reusing this type of plastic. By raising awareness about the dangers associated with Type 7 plastic, we can encourage safer alternatives and promote better practices in plastic consumption.

Read more: Different Plastic Types: What You Need to Know

3. Conclusion

In summary, the challenges associated with hard-to-recycle plastics like PVC, polystyrene, and Type 7 plastics underscore the urgent need for sustainable alternatives. These types of plastic pose significant health and environmental risks, highlighting the importance of responsible consumption and awareness. By promoting recycling and encouraging the use of safer materials, we can mitigate the negative impacts of plastic waste. Transitioning to a circular economy will be essential for protecting our planet and ensuring a healthier future.

4. About EuroPlas’ BiONext Products

At EuroPlas, we proudly introduce BiONext, a biodegradable bioplastic compound made from renewable sources such as polylactic acid (PLA) and polyhydroxyalkanoate (PHA). Products made from BiONext can completely decompose within 12 months, producing CO2, water, and biomass, which can be used as agricultural fertilizer, contributing to a sustainable life cycle.

The greatest advantage of BiONext is its biodegradability, making it a perfect solution for reducing plastic waste. In addition to being environmentally friendly, BiONext biodegradable plastic granules possess outstanding mechanical properties, including high hardness, excellent impact strength (ideal for injection molding and extrusion), and good elongation (suitable for blown film products).

With a glossy and attractive surface, BiONext meets both functional and aesthetic requirements for a wide range of finished products. BiONext is widely used in various applications, including bioplastic packaging, biodegradable shopping bags, food wrap, agricultural mulch films, food containers, disposable bowls, chopsticks, cups, spoons, and forks.

Choose BiONext to join hands with EuroPlas in building a greener world! For more information and specific inquiries, please contact us through the Contact Us page on our website.