What are antioxidant plastic additives and their applications in the plastic industry?

Most polymers are commonly subject to oxidation, leading to the degradation of end-products. In order for strengthening end-products’ quality, antioxidant plastic additives have been introduced to the plastic manufacturing process. In this article, let’s discover how this powerful substance works and its impacts on our plastic industry.

Plastic products, while durable and flexible, are always put at risk of degradation due to a large number of environmental factors (such as oxygen, UV light, high temperature,...) throughout their lifecycle. That’s why the use of plastic additives plays an indispensable part in plastic manufacturing, in which antioxidant plastic additives may be the most familiar name.

Read more: What are plastic additives? 8 most common plastic additives in plastic industry

1. Antioxidants and their application in the plastic industry

Antioxidant plastic additives are commonly used to prevent the negative impacts of oxidation on plastic products. As we all know, oxidation is a common phenomenon taking place when free radicals react to a material’s molecules, thus activating a chemical chain reaction. This eventually ends up in the degradation of the products themselves.

In the plastic industry, oxidation is even more harmful as it occurs in both stages of a plastic product: first during the manufacturing process and then throughout its lifecycle.

In the first stage, this phenomenon takes place when oxygen is introduced into the molecular structure of the polymer, resulting in chemical chain reactions and a permanent change within the plastic, most typically in molecular weight reduction. This process speeds up in thermoforming (blown film, film casting, blown molding,...) and injection molding, which leads to severe consequences such as mechanical properties degradation on final products. In order to minimize these negative impacts, antioxidant plastic additives must be added during the manufacturing process and act as a process stabilizer to prevent oxidation from transforming plastic components.

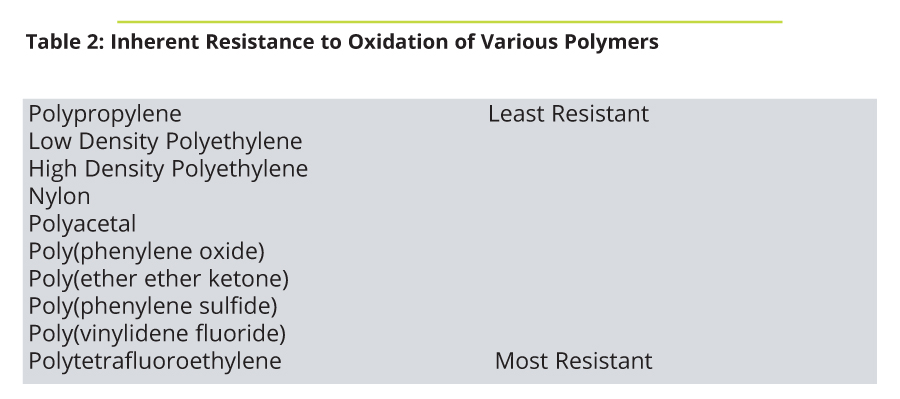

When it comes to the other stage, which is also the longer one, antioxidant plastic additives are introduced to protect end-products from harmful environmental factors as well as enhance their durability over their lives. Besides, certain products are more vulnerable to oxidation than others, which can be mainly explained by their plastic resins. The resistance ability to oxidation of various resins is illustrated in the table below:

The resistance ability to oxidation of various resins Normally, plastic products that are likely to contain antioxidant plastic additives include:

The resistance ability to oxidation of various resins Normally, plastic products that are likely to contain antioxidant plastic additives include:

- Pipes and fittings in the building & construction industry: As most of these are used outdoors, they have to be exposed to external environmental factors for a long period, which tends to lead to the presence of oxidation. Thereby, the application of antioxidants to these is very vital. - Polyethylene (PE) films (for construction or food industry): Though PE films are not the most severely affected by oxidation over their lifecycle, they are the most impacted during manufacturing. Oxidation is the main element causing mechanical degradation for PE films. Polypropylene (PP) products: Similarly, PP products also contain antioxidant plastic additives to protect products from the negative effects of oxidation.2. Common types of antioxidant plastic additives

As mentioned above, oxidation takes place in both stages of a plastic product, which means the use of antioxidant plastic additives is also corresponding to this. Basically, this substance is divided into 3 main categories in order to serve specific functions.

- Primary: This type is mainly used for end-products during their service lives to protect themself from oxidation and other harmful environmental factors. Normally, the antioxidant plastic additives of this group are phenolic-based.

- Secondary: Secondary antioxidant plastic additives act as a processing stabilizer to protect the polymer from being degraded by oxidation during the manufacturing process, especially when the polymer undergoes multiple thermal methods (blown film, injection molding,...). Typical chemistries employed include phosphites or thioesters.

Without antioxidant plastic additives, plastic surface is easily oxidized

Without antioxidant plastic additives, plastic surface is easily oxidized

Primary & Secondary combination: Not only are primary and secondary antioxidants used separately but they are also used with each other to optimize the benefits gained. In this way, plastic products are protected both during the processing step and throughout their lifecycle. That means plastic manufacturers can reap lots of benefits as they are provided with high-quality outputs, while end-users are also satisfied with better long-lasting end-products. Depending on the characteristics of end-products and their uses, plastic manufacturers can choose appropriate types of antioxidant plastic additives. For example, packaging products should use antioxidants during the manufacturing process as their oxidation mainly takes place during this process. Whereas, outdoor plastic products should take primary and secondary antioxidants as it occurs in both the manufacturing process and service life.3. How to use antioxidant plastic additives correctly?

As a large number of plastic products go to food-contact applications, concern regarding customers’ health safety has been arising. According to scientific research, the migration of plastic additives from polymer packaging into food actually happened, which more or less poses a health threat to consumers. Therefore, the determination of additives content in polymers is an important component of the safety assessment of food packaging materials, the quantification and specific migration levels (SMLs) of these additives are also very important for the quality control of food. As such, when it comes to the amount of antioxidant plastic additives used, plastic manufacturers should take it very seriously to ensure the outputs are completely harmless to human beings.

Besides, the technical requirements and uses of end-products should also be taken into consideration to figure out the most suitable components for your products.

4. EuroPlas additives

15+ years of development, EuP has expanded its business to not only filler masterbatch manufacturing, but also additives production. We bring customers a wide range of additives to fully meet their requirements, which include: anti-UV additives, anti-aging additives, processing aids, and brightening agent,...

EuroPlas plastic additives

EuroPlas plastic additives

With the highest quality components, state-of-the-art technology, and qualified staff, EuroPlas additives have been provided for customers in various industries such as packaging film, injection molding products, and extrusion,... We proudly bring our customers timely support to ensure that you are able to choose the most appropriate plastic additives that exactly meet your end-products characteristics, thus enhancing your products’ competitiveness. Besides, the consultation service is also introduced to customers regarding loading rate, components, and manufacturing method to optimize the using effectiveness, as well as minimize the unexpected that may arise during the manufacturing process.

For more information and consultation, contact us!