PBAT plastic is one of the popular bioplastics on the market. Currently, PBAT plastic contributes benefits in most areas related to the life and health of consumers. Learning about the in-depth effects of PBAT plastic helps us find the development direction of the bioplastic industry. In this article, EuroPlas will analyze in detail the application potential of PBAT plastic in life.

1. Overview of PBAT plastic

PBAT or Polybutylene Adipate Terephthalate is classified by manufacturers as a thermoplastic polymer. They have become the perfect replacement for traditional plastic materials made from petroleum. In essence, the origin of PBAT plastic is mostly from natural and highly renewable raw materials, typically: Corn, cassava, tapioca starch or sugarcane starch. In terms of chemical structure, PBAT plastic is synthesized from polymers of 1,4-butanediol and adipic acid and polymers of dimethyl terephthalate (DMT) with 1,4-butanediol. Adipic acid and 1,4-butanediol are polymerized to form their polyester (plus water). DMT and 1,4-butanediol also react to form their polyester (plus methanol).

The most outstanding feature of PBAT plastic is to minimize the impact on the surrounding environment due to its sustainable biodegradability over time. It is simply understood that microorganisms in the natural environment will easily impact and decompose the components and structures of PBAT plastic after a long time of use. Therefore, while the decomposition time of traditional plastic materials can be up to hundreds of years, PBAT plastic only takes a few years to completely disappear in nature.

-m%E1%BA%B7c-d%C3%B9-nh%E1%BB%B1a-sinh-h%E1%BB%8Dc-n%C3%B3i-chung-v%C3%A0-v%E1%BA%ADt-li%E1%BB%87u-pbat-n%C3%B3i-ri%C3%AAng-v%E1%BA%ABn-c%C3%B2n-kh%C3%A1-m%E1%BB%9Bi-m%E1%BA%BB-t%E1%BA%A1i-th%E1%BB%8B-tr%C6%B0%E1%BB%9Dng-vi%E1%BB%87t-nam,-c%C3%A1c-t%E1%BA%ADp-%C4%91o%C3%A0n-c%E1%BB%A7a-ch%C3%BAng-ta-%C4%91%C3%A3-v%C3%A0-%C4%91ang-th%E1%BB%B1c-hi%E1%BB%87n-c%C3%A1c-chi%E1%BA%BFn-l%C6%B0%E1%BB%A3c-ph%C3%A1t-tri%E1%BB%83n-lo.jpg)

In addition, PBAT plastic is highly appreciated by manufacturers because of its adaptability. The mechanical properties of this type of plastic can be significantly improved by reinforcements such as plastic additives, biodegradable polymers or they can still be combined with traditional plastic lines to improve the cost and quality of the product.

Moreover, PBAT plastic completely meets the processing steps using conventional plastic processing techniques. Therefore, we can basically understand why PBAT plastic is widely used in fields directly related to the life and health of consumers such as: Fast-moving consumer goods, food packaging, household goods, healthcare, electronics or automobiles.

In the next section, EuroPlas will discuss in detail the useful effects of PBAT plastic in human life. Check it out now!

2. Effects of PBAT plastic

Although bioplastics in general and PBAT materials in particular are still quite new in the Vietnamese market, our corporations have been implementing strategies to develop this type of plastic. Therefore, they are also present in a number of important fields, specifically as follows:

-

Agriculture: This is the main field of PBAT plastic. Key products such as humus film, greenhouse film and silage film. The two core properties for PBAT plastic to be suitable in the agricultural sector are moisture resistance and toughness because the hardness & elastic modulus of PBAT plastic are quite low. In particular, the nature of PBAT plastic is from natural ingredients, so it will not affect the quality of crops.

-

Fast-moving consumer goods (FMCG) industry: According to the Communist Magazine report in 2022, the amount of plastic waste in Vietnam accounts for 8 - 12% and is mostly from fast-moving consumer goods. Therefore, bioplastics in general and PBAT plastics in particular are gradually replacing traditional plastics, becoming fuel for the production of products such as: Shampoo bottles, soap boxes and toothbrushes.

-h%E1%BA%A1t-nh%E1%BB%B1a-pbat-%C4%91%C6%B0%E1%BB%A3c-%E1%BB%A9ng-d%E1%BB%A5ng-trong-l%C4%A9nh-v%E1%BB%B1c-nh%C3%A0-h%C3%A0ng-kh%C3%A1ch-s%E1%BA%A1n.jpg)

-

Food industry: PBAT plastics have quite good barrier and antibacterial properties, they can separate liquids and gases to minimize the impact of the environment on the product. Therefore, PBAT plastics are the perfect choice in the food industry and are produced into main finished products such as: Fruit and vegetable bags, fast food packaging, cereal boxes. The barrier created by PBAT plastics will prevent air from carrying bacteria into the food, thereby preserving it longer and not affecting the health of consumers.

-

Medical field: PBAT plastics are not only flexible, stable and self-degradable, but also antibacterial and easily combined with other natural compounds. They ensure health issues and fuel cleanliness, so PABT is produced into basic medical products such as: absorbable sutures, wound dressings, clamps and other tools. In general, practicality and environmental friendliness help PBAT plastic become an input fuel source in many important fields. In the current context, this will be one of the suitable choices to gradually replace traditional plastics according to the green development orientation of countries around the world.

Besides the 4 key applications above, PABT plastic also has 3 disadvantages that need to be noted. They will be analyzed in detail in the next section.

3. Disadvantages of PBAT plastic

Bioplastics in general and PBAT plastic in particular require a professional production process with many modern equipment and a high-quality workforce. Therefore, the cost of producing PBAT plastic will also be higher than traditional plastics.

Although PBAT is a bioplastic with good biodegradability and is environmentally friendly, its popularity is not too widespread because the cost of raw materials is quite high.

In addition, PBAT also has weaknesses that cannot be compared with traditional plastics. Their popularity is affected because their heat resistance and UV resistance are lower than traditional plastics. This has directly affected the availability and practicality of this material. Therefore, PBAT plastic has certain limitations in certain industrial fields.

Finally, bioplastics in general have the potential to affect the quality of the environment if the decomposition process is not carried out according to standard procedures. The composting process also requires specific conditions to decompose the material effectively. Therefore, manufacturers must pay close attention to each stage during the processing of PBAT plastic materials.

4. About EuroPlas's bioplastics and biofillers.

The disadvantages of PBAT plastic are not too significant and can be improved over time. In the context of climate change and environmental issues that are increasingly concerned, biomaterials such as PBAT plastic are focused on investment and become suitable choices in the fields of human health & life.

Because this is a bioplastic, they have very high requirements in selecting input materials, so choosing a reliable supplier is important. In this regard, EuroPlas is the leading masterbatch manufacturer in Vietnam, providing a variety of biological preparations to meet the needs of different industries. EuroPlas provides two biological preparations, BiONext biocompound and BiOMates biofiller.

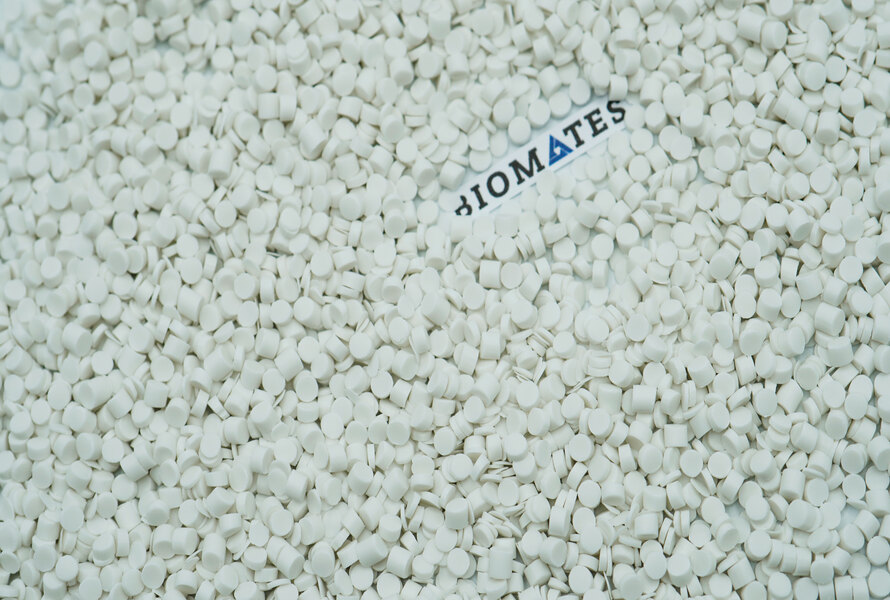

4.1 BiOMates biological filler

The main ingredient that makes up EuroPlas's BioMates biological filler is a mixture of bioplastics and modified ingredients, such as CaCO3, BaSO4, talc powder, along with dispersing additives. EurP's BiOMates biological filler is biodegradable and is an environmentally friendly choice. In addition, the good compatibility with other additives and plastic materials of BiOMates at EuroPlas helps manufacturers save a lot of costs.

Therefore, EuroPlas's BiOMates bio-filler is applied to many products such as: biodegradable films, toothpicks and dental floss, straws, thermoforming trays, disposables, shopping bags, food packaging films, roll films and coating films.

4.2 BiONext Bioplastics

EuroPlas has combined bioplastics and other ingredients such as reinforced CaCO3 powder, modified starch powder, specialized plasticizers, talc powder and specialized additives to create the most perfect BiONext material.

Therefore, the properties of BiONext bioplastics are highly appreciated by manufacturers. They are capable of safely decomposing within 12 months. In addition, BiONext also possesses high hardness, low melt flow index, high impact resistance and is easy to process. In particular, EuroPlas's BiONext has become the leading material in the food packaging industry due to its ability to retain surface moisture for a long time.

In general, these are two materials that combine well with PBAT resin and will complement each other's properties to expand their applications in many different fields. In particular, EuroPlas' biological products always ensure environmental friendliness and safety for consumers' health.

5. Conclusion

EuroPlas has introduced in detail the diverse applications of PBAT resin in human life. We also mentioned the advantages and disadvantages of this material. In particular, the EuroPlas team is also very proud of its biological products. Please continue to follow EuroPlas to update the news about plastic materials as soon as possible!