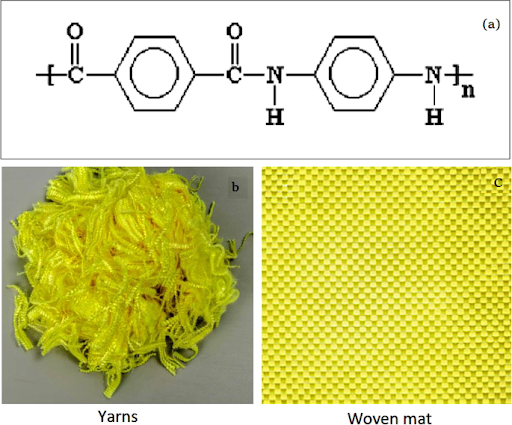

Aramid fiber formula

In engineering composites, synthetic fibers are one of the most common applications. Some types of synthetic fibers can be named as aramid fiber, carbon fiber, glass fiber, etc. Among them, aramid fiber can be considered one of the outstanding materials with diverse applications. When talking about aramid fiber, people often think of one of the leading materials in the world of synthetic fibers. In terms of properties, aramid fiber is a fiber with high heat resistance and tensile strength many times higher than other materials. To better visualize aramid fiber, this is an important material for producing bulletproof vests, firefighter uniforms, body armor or protective vests for cyclists thanks to the above properties. Scroll down below to update more useful information about this material!

1. What is Aramid Fiber?

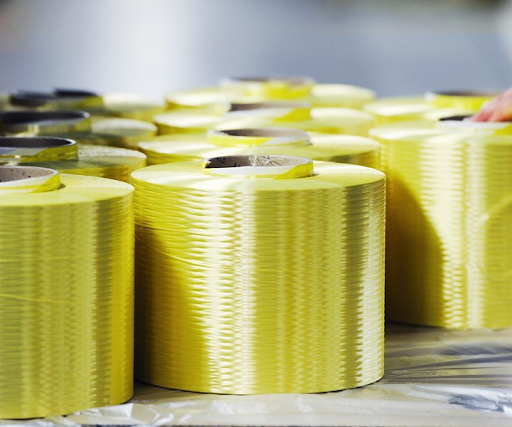

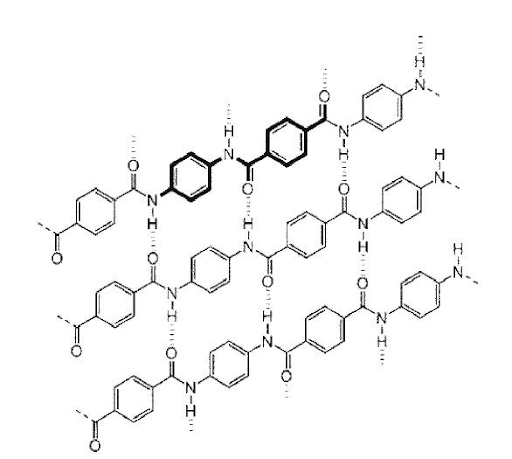

Aramid fiber rolls

Aramid fiber belongs to the group of synthetic fibers whose full name is "aromatic polyamide". They have a similar chemical formula to nylon but instead they have aromatic carbon chains that make the properties of aramid silk fibers significantly different. A long-chain synthetic polyamide fiber serves as a filament forming agent in the production of aramid fiber, in which at least 85% of the amide bonds, (−CO−NH−) are directly attached to two aromatic rings. Thanks to the orientation of the molecular chains along the axis, the chemical bond of aramid fibers is much higher than that of other materials. The strength of aramid fiber is 5 to 6 times higher than steel wire but the weight is only 1/5 of steel wire. The melting temperature of aramid fiber is quite high, up to more than 500 degrees Celsius, which can be considered to have very good heat resistance performance. The application of aramid fiber is an optical milestone in the military, aerospace and transportation materials industry.

Aramid fiber stands out with many advantages

Aramid fiber stands out among a series of other fibers with the advantages just mentioned. Many manufacturers prefer aramid because of its good chemical resistance, high elongation, and excellent impact and abrasion resistance that provide extremely high product performance for investors. Producing products using aramid fiber not only improves durability but also saves weight, helping the engine consume less energy, which means bringing more economic benefits.

2. What types of Aramid Fiber?

Aramid fibers are divided into two main types as follows:

2.1 Meta-aramid

Meta-aramid has a high thermal stability

Meta-Aramid is an aromatic polyamide and has a zig-zag chemical bond configuration. This type has advantages such as high thermal stability, good resistance to chemicals and ultraviolet rays. Currently, the price of meta-aramid is lower than the other types because of differences in some properties. However, this type has better heat resistance and is used as a fireproof textile material for firefighters.

2.2 Para-aramid

Para-aramid has an outstanding abrasion resistance

Unlike meta-aramid, the chemical bond profiles of para-aramid fibers are more aligned in the long direction of the fiber. This type has a higher price thanks to its outstanding advantages such as higher durability, elasticity and outstanding abrasion resistance. Thanks to that, para-aramid fibers are widely used to make load-bearing panels, reinforcing fibers for technical structures or applications that require materials with high tensile strength.

In general, the designations meta and para are used to distinguish differences in their binding configurations. Meta has a zig-zag shape while para has a straighter line.

3. Characteristics of Aramid Fibers?

3.1 Chemical properties

Hydrophilic bonds in aramid fiber

The main chemical property of aramid is that most of them contain hydrophilic bonds. However, aramid products have different levels of moisture absorption. Besides, aramid fibers when exposed to UV rays at high frequencies and for too long a time can cause an oxidation reaction. This can cause them to change color.

3.2 Thermal properties

Aramid fibers have extremely good heat resistance

Aramid fibers have extremely good heat resistance. There are many studies showing that when heated in an environment of 300 degrees Celsius, this type of material still retains a fairly high durability of about 50 - 60%. Thanks to the special property of high crystallinity, when exposed to high temperatures, aramid fibers shrink insignificantly.

3.3 Mechanical properties

Aramid fiber has an index of up to about 3045 MPa

Aramid fiber has a breaking strength 5 times higher than steel, with an index of up to about 3045 MPa. When subjected to strong bending, aramid fibers exhibit excellent ductility, with no significant damage observed after strong impact with a tension of about 0.3%. At high temperatures, this fiber still exhibits extremely good elasticity. This type of fiber can be easily combined with other materials. For example, aramid fiber can be combined with epoxy to create water resistance, or combined with rubber to enhance flexibility.

4. Key Applications of Aramid Fiber?

Fire protective clothing made of aramid fiber

Fire protective clothing: thanks to its excellent heat resistance, fabrics made from aramid fibers are widely used to design protective clothing for firefighters from clothes, helmets or heat-resistant shoes. A typical example is military clothing MIL-G-181188B.

Anchor brake lining made from aramid fiber

Acts as an asbestos replacement: as many warnings have emphasized, asbestos can cause a series of serious diseases when inhaled by humans and is banned in many countries. Currently, aramid fiber can fully meet the requirements to replace this material and is completely safe for human health. Typical products such as brake pads, roofing sheets, etc.

Aramid fiber used in military

Production of protective clothing: due to its excellent durability, abrasion resistance, and formability, aramid fibers are used to produce protective armor for athletes, cyclists, and are also used in the military.

Aramid fiber used as cables for engineering project

Used as cables for engineering projects: a typical example is the hydroelectric tower for Hydro Quebec that uses aramid fibers as conductors for erection. Thanks to its high breaking elongation.

Production of sports equipment: typical examples are sailcloth for boats, boat hull materials, skis, tennis strings, hockey sticks, etc.

The applications of aramid are very diverse

The applications of aramid are very diverse, some other products that can be mentioned are tires, fire wicks, drums, fiber optic cable systems, fiber reinforced concrete, jet engine casings, thermoplastic pipes. reinforcement, hot air filter cloth, etc

5. Conclusion

Overall, aramid fiber is one of the materials that brings benefits to users and manufacturers alike. Products made from aramid fibers have always been consumers' companions for many years thanks to their perfect durability. In addition, aramid fiber helps manufacturers create outstanding product effects, high efficiency, saves operating fuel and brings good economic efficiency to businesses. Learn more about a series of diverse articles at EuroPlas on the topic of materials for your project today!