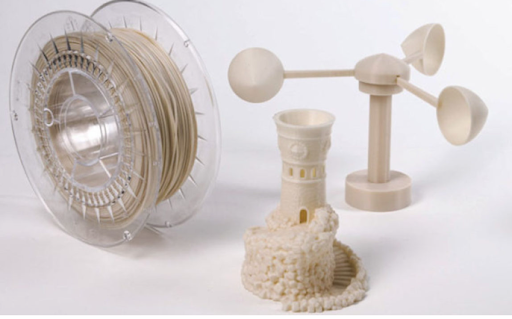

ASA filament are aimed at long-term use over many years

Responding to today's demand for production according to high quality criteria, ASA filament seems to have done this very well. Applications made from ASA filament are aimed at long-term use over many years. When talking about ASA filament, we will easily see some basic descriptions such as durability, weather resistance, chemical resistance, etc. The application of ASA filament to projects has long helped many investors save large costs in product maintenance and repair. In addition, the durability of ASA filament helps manufacturers achieve the ideal level in improving product performance even through many rainy and sunny seasons. Not stopping there, ASa filament also possesses many other optimal features that information can be easily updated with just the article below.

1. What is ASA filament?

ASA filament has a melting point around 110°C

The materials industry in general and some projects in particular have long widely applied ASA filament in the production process. In ASA filament, butadiene resin is the key ingredient. ASA filament is produced from ASA (Acrylonitrile styrene acrylate), which is a synthetic, amorphous thermoplastic with the chemical formula C18H23NO2. The grafted acrylic ester elastomer (in powder form) is added during the copolymerization of acrylonitrile and styrene to form ASA. ASA filament has a melting point around 110°C. ASA filament stands out in the textile industry with outstanding features such as chemical resistance, good weather resistance, good heat resistance, UV rays and some radiation from the outside environment. Because it possesses optimal functions, ASA filament is commonly used for outdoor projects such as playgrounds, backyards, porches, etc. In addition, industries with high demand for ASA filament include electronics, housing components, garden equipment, sports equipment, automotive technology, etc. Not only diverse in applications, ASA filament can also be produced in a variety of processes such as hot pressing, injection molding, extrusion, blow molding, 3D printing, etc.

Read more: About ASA plastic: What is it?

2. ASA filament properties

The properties of ASA filaments are based on their monomer composition (acrylonitrile, styrene and acrylate). These monomers give ASA filament its excellent heat resistance, chemical and radiation resistance. Besides, the durability, hardness and stability of the ASA filament door are also one of the plus points for this material.

ASA filament has excellent heat resistance, chemical and radiation resistance

Below are some mechanical parameters of the ASA filament:

- Hardness: ≅ Shore D 68-110

- Thermal deviation temperature: ≅ 92°C

- Tensile strength: 35.0 - 50.5 MPa

- Glass transition temperature: ≅ 112°C

- Density: 1.06 - 1.09 g/cc

- Tensile modulus: 1,786 - 2,468 MPa

- Flexural strength: 38.6 - 78.6 MPa

2.1 Protects against UV rays and some other radiation

Parts manufactured from ASA fibers are extremely resistant to UV rays. Therefore, ASA filament is designed for outdoor applications, subject to many years of sun and rain. However, in harsh weather conditions, ASA filament still keeps parts shiny and does not fade. This is also the reason why ASA filament is always considered a commitment to longevity

2.2 High impact resistance, tough and durable

Most products made from ASA filament are intended for long-term use. The main reason for this trend is because ASA filament is very durable, has good stiffness and excellent impact resistance. This property helps parts made from ASA to be less deformed or damaged when there is a strong impact, helping to minimize cost losses for users. The automotive industry widely uses ASA filaments because of their good stability and impact resistance.

2.3 Resistance to chemical corrosion

Chemical resistance is one of the outstanding advantages of ASA fiber. ASA filament can resist abrasion by a variety of chemicals such as vegetable or animal lubricating oils, saturated hydrocarbons, weak acids and alkalis, and water. This property helps ASA fiber maintain its position as one of the strongest materials, stronger than some metals. Because of exposure to harsh environments but the level of damage is extremely small, products made from ASA filament help users save a large amount of maintenance and repair costs.

2.4 ASA filament is water resistant

Parts made from ASA fibers can withstand long-term direct contact with water without being damaged. This makes ASA fiber one of the ideal choices for many residential projects, entertainment areas, sports fields, etc. These applications often require a material that can withstand multiple seasons of rain, fog or moisture.

Some of ASA filament outstanding properties

3. ASA filament applications

The applications of ASA filament are based on its properties of UV and radiation resistance, chemical resistance and durability. Most applications of ASA filament require outdoor durability.

Most applications of ASA filament require outdoor durability.

Famous for its resistance to UV rays, radiation and corrosive chemicals, ASA filament is very suitable for applications in the garden, porch, or children's playgrounds. Products such as tables, chairs, plant pots, swings, and slides designed from ASA fibers are always very durable because they can withstand harsh weather conditions for long periods of time. In addition, the product also retains its shine and beautiful color over the years. In particular, the equipment rarely rusts or deteriorates despite experiencing many sunny and rainy seasons.

- Design protective covers for some devices

ASA fibers are used to design covers for industrial equipment because they can withstand harsh environments (sunlight, UV rays, water and chemicals). The protective cover made from ASA fiber will help prevent machinery and equipment from being damaged by weather, saving maintenance costs and costs arising from damage. In addition, high-value products also need a sturdy protective layer made from ASA filament. For example, it is applied in automotive technology, ship and yacht hulls or home construction equipment. These applications help maintain product aesthetics in aspects such as gloss, color, deformation resistance, and abrasion to the original design.

Industrial parks and commercial centers need durable shields to protect equipment, machinery, and facilities for long-term survival. In addition, some machines with specific characteristics need to be separated to avoid harming people, especially children. ASA filament is the ideal material in this case. These protective shields are often able to withstand harsh weather, are extremely durable and have perfect impact resistance.

Sports products using ASA fibers include shoes, accessory soles, and racks for training tools. In environments that can face a high frequency of impacts, sports products made from ASA filament can retain their original shape without breaking or deforming. In addition, some athlete protective equipment is also made from ASA filament... These products often have flexible, durable and impact-resistant properties to help ensure safety during exercise or sport match.

ASA filament is very suitable for applications in the garden and porch

4. Notes when printing ASA filament

ASA filament temperature needs to be maintained appropriately

4.1 ASA filament temperature

The ASA filament temperature when printing needs to be maintained at about 240-260 degrees Celsius. This temperature helps the 3D printing process achieve the best results and produce good quality products. Besides, the manufacturer also needs to maintain the bed temperature in the range of 90-120 degrees Celsius. Above is the average temperature level, depending on the ratio of raw materials, the above parameters will be adjusted accordingly. about 3 -5 degrees Celsius. Care must be taken in determining the appropriate printing temperature to avoid the material being broken or warped.

4.2 Print speed

For a product printed from ASA filament to be perfect, manufacturers need to note that the ideal printing speed for this material is 50 mm/s. Just like temperature, depending on the ratio of raw materials, the manufacturer can adjust the differential printing speed. To be safe, you can start printing at a speed of 30 mm/s and gradually increase to find the ideal speed.

4.3 Bed adhesion

Bed adhesion also greatly determines whether the printing process is successful or not. One reason is that if the ASA filament sticks to the print bed, it will help minimize warping or breakage during the process. To process the print beds, the manufacturer needs to warm them up before proceeding. The ideal temperature to heat the print bed before starting the ASA filament printing process falls around 90 -120 degrees Celsius. In addition, the manufacturer Production needs to pay attention to a number of other factors such as cleaning the print bed surface, bed balance, etc.

4.4 Glass bed

The glass bed is also one of the important factors in the ASA filament printing process. If the glass bed is built unevenly, the printing results will not be as expected. Choosing a flat, closed bed and balancing the glass bed will help print the product more perfectly and make it easier to pick up the print when the substrate cools.

5. Conclusion

Overall, the properties that ASA filament possesses are worthy of placing them on the list of top durable materials. If you are looking for materials for outdoor projects, or applications that require hardness and impact resistance, ASA filament is an ideal choice. Read more useful shares from EuroPlas, we always accompany you in finding an optimal material!