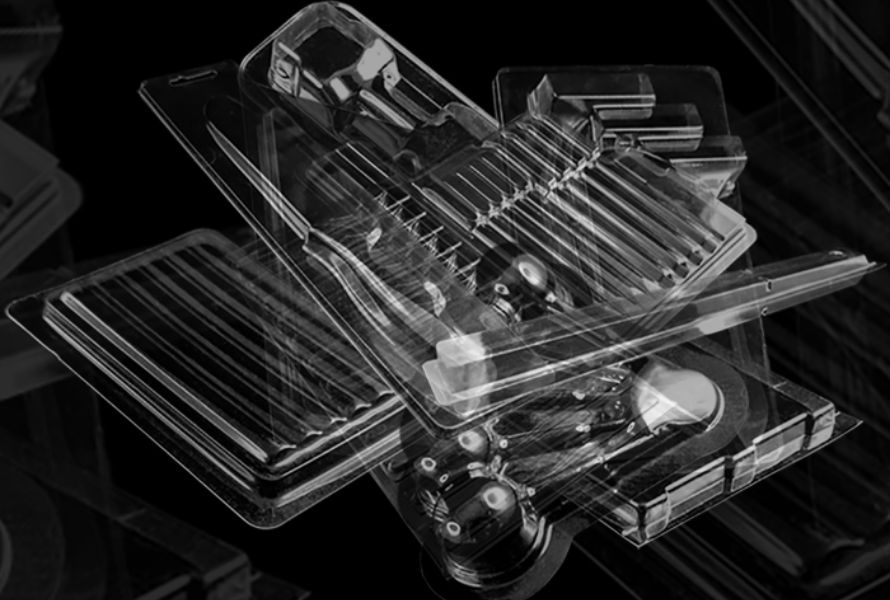

Blister packaging is a popular packaging method known for its ability to protect products while enhancing their visual appeal. In this comprehensive guide, we will delve into the world of blister packaging, exploring its definition, benefits, and the different types available in the market today.

1. What is blister packaging?

Blister packaging refers to a type of packaging that involves a transparent plastic cavity or blister that securely holds a product while providing a clear display of its contents. The blister is typically sealed to a backing card or blister tray, creating a protective enclosure for the product. The primary purpose of blister packaging is to protect the product during storage, transportation, and display, while also allowing consumers to see the product before purchase.

Blister packaging is a type of packaging consisting of a pre-formed plastic blister or cavity that is used to enclose and protect a product

2. Types of blister packaging

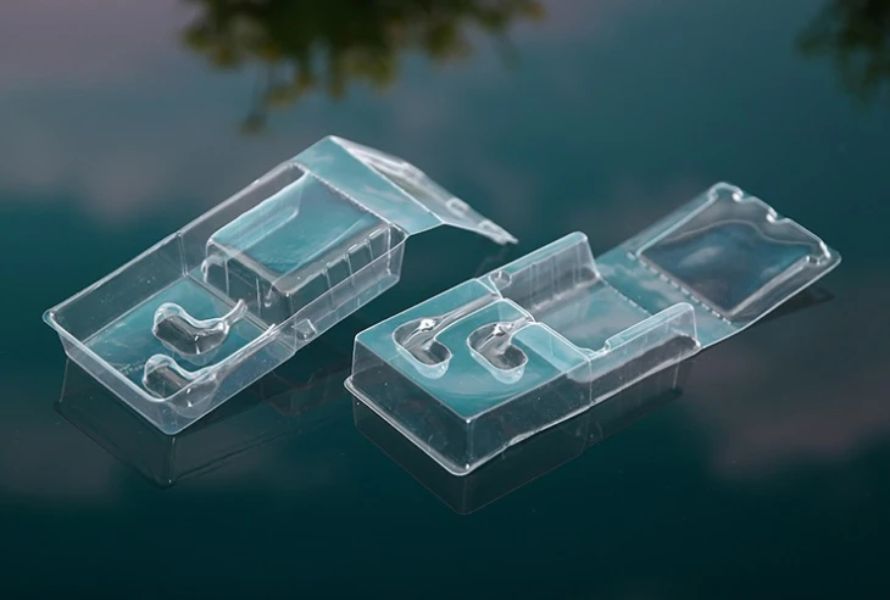

2.1. Clamshell Blister Packaging

Clamshell blister packaging consists of two hinged halves that enclose the product like a clamshell. It provides excellent product visibility while offering a high level of protection. Clamshell packaging is known for its durability, as it is typically made from rigid materials like PVC or PET. The secure closure of the clamshell helps prevent tampering and damage, making it suitable for fragile or valuable products.

Clamshell blister packaging is widely used in various industries, including electronics, consumer goods, and toys. It is particularly popular for packaging items such as electronic accessories, small appliances, tools, cosmetics, and small parts. The clear, sturdy design of clamshell packaging allows consumers to examine the product closely while providing optimal protection during transit and display.

The product is enclosed in a clamshell-like packaging made of two hinged halves called clamshell blister packaging

2.2. Face Seal Blister Packaging

Face seal blister packaging involves a transparent blister that is heat-sealed directly to a blister card or backing. This type of packaging offers a tight seal around the product, providing a tamper-evident and secure enclosure. Face seal blister packaging allows for efficient product visibility and branding, with the backside of the card serving as a space for product information and graphics.

Face seal blister packaging is suitable for a wide range of products, including small consumer goods, pharmaceuticals, and personal care items. It is commonly used for packaging items like batteries, stationery, over-the-counter medications, and cosmetics. The face seal design offers protection against tampering and contamination, making it ideal for products that require a high level of security and visibility.

Face seal blister packaging is when a clear plastic blister is heat-sealed directly onto a printed card or backing material

2.3. Carded Blister Packaging

Carded blister packaging involves a transparent blister that is sealed to a printed cardboard backing. This type of packaging combines the visibility of the blister with the branding and information provided by the cardboard backing. The blister securely holds the product, while the card serves as a platform for product details, branding elements, and instructions.

Carded blister packaging is widely used in retail settings for various products, including toys, hardware items, electronics, and personal care products. The combination of the blister and card allows for effective product display, product protection, and consumer communication. The printed card offers ample space for branding, product descriptions, and instructions, enhancing the overall presentation and consumer appeal.

Carded blister packaging is a type of blister packaging where a clear plastic blister is sealed to a printed cardboard card

2.4. Slide Blister Packaging

Slide blister packaging consists of a blister that is enclosed within a cardboard sleeve or sleeve-like structure. The blister can be accessed by sliding it out of the sleeve, providing easy product removal and reinsertion. This type of packaging allows for repeated use while maintaining product visibility and protection.

Slide blister packaging is commonly used for products that require frequent access or have multiple components, such as hardware items, small tools, craft supplies, and electronics accessories. Industries that benefit from slide blister packaging include DIY, hobby, and electronic sectors. The slide feature offers convenience and efficient storage, while the blister and sleeve combination ensures product protection and visibility.

Slide blister packaging is a type of blister packaging that incorporates a sliding mechanism

3. Benefits of blister packaging

3.1. Enhanced Product Visibility and Marketing Appeal

Blister packaging provides a transparent window that showcases the product, allowing consumers to see its size, color, shape, and other distinctive features. This visibility enables customers to evaluate the product's quality, aesthetics, and functionality, leading to informed purchasing decisions.

Moreover, blister packaging offers design flexibility, allowing companies to create visually appealing packaging that stands out on store shelves. With the ability to incorporate vibrant graphics, logos, and product information, blister packaging helps capture consumer attention and differentiate the product from competitors.

3.2. Protection against Tampering, Contamination, and Damage

Blister packaging provides a tamper-evident solution, assuring consumers that the product has not been interfered with or compromised. The sealed blister effectively detects any attempts at tampering, promoting product safety and consumer trust.

Blister packaging acts as a protective shield, guarding the product against environmental factors such as moisture, dust, light, and oxygen. This barrier helps maintain the product's quality, freshness, and efficacy, particularly in industries like food, pharmaceuticals, and electronics.

3.3. Extended Shelf Life and Freshness Retention

Blister packaging can be designed to create an airtight seal around the product, preventing air and moisture from entering and affecting its quality. This airtight environment helps preserve the product's freshness, taste, aroma, and texture, extending its shelf life.

Blister packaging can incorporate materials with barrier properties, such as foil or specialized films, to shield the product from moisture, light, and oxygen. These elements can degrade the product's quality, stability, and shelf life, making effective protection crucial, especially for sensitive products like pharmaceuticals or perishable goods.

Blister packaging offers several benefits for both manufacturers and consumers

4. Types of plastic used in blister packaging

4.1. PVC (Polyvinyl Chloride)

PVC is a widely used plastic material in blister packaging. It is known for its excellent transparency, flexibility, and ease of forming. PVC blister packaging provides good product visibility and protection against moisture, dust, and physical damage.

4.2. PET (Polyethylene Terephthalate)

PET is another popular plastic material used in blister packaging. It offers high clarity, strength, and durability. PET blister packaging provides excellent barrier properties against moisture, oxygen, and other external factors, making it suitable for products that require enhanced protection.

4.3. PS (Polystyrene)

Polystyrene is a commonly used plastic for blister packaging. It is lightweight, rigid, and has good clarity. PS blister packaging is often used for products that require a more economical option and do not need high barrier properties.

4.4. PP (Polypropylene)

Polypropylene is a versatile plastic material used in blister packaging. It offers good transparency, impact resistance, and durability. PP blister packaging is suitable for products that require a more rigid and robust packaging solution.

4.5. PLA (Polylactic Acid)

PLA is a biodegradable and compostable plastic derived from renewable resources such as cornstarch or sugarcane. It is used as an environmentally friendly alternative to traditional plastics in blister packaging, particularly for applications where sustainability is a priority.

Blister packaging often utilizes plastic materials to create the clear plastic blister and provide a protective barrier for the product

5. Conclusion

Blister packaging is a versatile packaging solution that offers both protection and visual appeal for a wide range of products. The different types of blister packaging, including clamshell, face seal, carded, and slide blister packaging, cater to various industries and product requirements. By understanding the benefits and characteristics of each type, businesses can make informed decisions about the most suitable blister packaging option for their products.

In addition, if you are looking for a source of plastic for blister packaging, EuroPlas is the place you can trust. Here, we provide many types of high quality and standard plastics such as PP filler masterbatch, PP flame-retardant compound,... Coming to us, you can be completely assured with the quality of your output products.

To explore more informative content, feel free to check out the EuroPlas blog or reach out to us for a discussion about our products and services!