Ethylene vinyl acetate, commonly known as EVA, is a co-polymer formed through polymerization. Currently, this material has been widely applied in various industries. Take a look at the properties that make EVA stand out and explore the diverse fields where Ethylene vinyl acetate is widely used.

1. What is Ethylene vinyl acetate (EVA)?

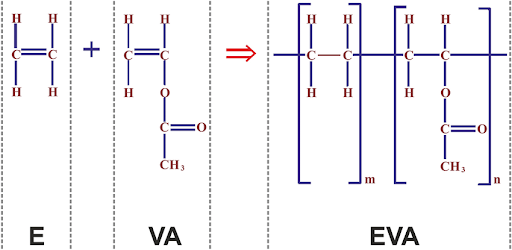

Ethylenevinyl acetate (EVA) is known as a copolymer, originating in the 1950s and manufactured by DuPont. In particular, copolymer is a type of polymer made from two or more different monomers through the polymerization process. Monomers are basic units, and when they join together, they form long chains, called polymers.

Ethylene vinyl acetate (EVA) plastic consists of randomly distributed vinyl acetate chains interspersed with ethylene -ₓy chains. EVA is the result of copolymerization between ethylene and vinyl acetate, produced via block copolymerization or solution copolymerization.

Molecular structure of Ethylene-vinyl acetate

EVA plastic compositions typically range from 10 to 50% vinyl acetate, the remainder being ethylene. This unique blend allows for the creation of three distinct types of EVA copolymers, each tailored to specific applications across diverse industries. Whether in packaging, footwear, or other fields, EVA's adaptability and favorable attributes make it a go-to material, highlighting its enduring significance in modern polymer technology.

2. What are EVA polymer’s characteristics?

2.1. High flexibility and transparency

Ethylene vinyl acetate (EVA) stands out for its remarkable flexibility and soft touch. This characteristic allows it to be easily molded and shaped without losing its form, making it an ideal material for cushioning and padding. Notably, EVA maintains its flexibility even at low temperatures, adding to its versatility.

EVA exhibits high transparency, allowing light to pass through with clarity. This property is advantageous in applications where visibility or aesthetic appeal is important. The transparent nature of EVA makes it a suitable choice for various products, contributing to its versatility in design and functionality.

2.2. Lightweight

Thick sole made from very light EVA

Renowned for its lightweight nature, Ethylene-vinyl acetate finds widespread use in the creation of protective clothing and footwear. This characteristic enhances comfort for users while maintaining durability and flexibility.

2.3. Non-toxic

EVA is a non-toxic material, ensuring its safety for use in diverse settings, including childcare, the medical industry, and applications related to food. Its non-toxic nature adds to its versatility and broadens its range of applications.

2.4. High waterproof

EVA's high water resistance makes this plastic able to withstand rainy and windy weather, suitable for applications such as diving suits or raincoats exposed to water. This property ensures the EVA material remains reliable in a variety of weather conditions.

2.5. Low melting temperature

An advantageous property of ethylene vinyl acetate is its low melting temperature. This characteristic offers versatility in the manufacturing of textile products, allowing for easy bonding processes and facilitating the creation of a wide range of items.

Read more: What is the melting temperature of plastic?

2.6. Excellent durability and resistance

Products made from Ethylene-vinyl acetate are highly durable

Highly resistant to wear, tear, and abrasion, Ethylene-vinyl acetate proves its durability in various applications. Additionally, its resistance to multiple chemicals makes it a reliable choice for industrial settings where exposure to different substances is common.

2.7. Can reduce noise and low thermal conductivity

EVA's noise-reducing properties, along with its low thermal conductivity, make it valuable for applications requiring sound absorption or thermal insulation. This makes it a versatile material for diverse applications, including in the production of items that contribute to a quieter or thermally insulated environment.

2.8. Recyclable

Ethylene vinyl acetate is recyclable, contributing to efforts to reduce environmental impact. This characteristic is relevant today, where we have placed an increasing emphasis on sustainable practices, and as such, makes EVA an environmentally friendly choice.

2.9. High friction coefficient

A notable feature of Ethylene vinyl acetate is its high friction coefficient. This property enhances its grip and traction, making it an excellent choice for applications where slip resistance is crucial. Whether used in footwear, sports equipment, or industrial settings, EVA's high friction coefficient contributes to stability and safety. This characteristic is particularly valuable in scenarios where preventing slips and ensuring a secure grip are essential considerations.

3. What are the applications of EVA?

Ethylene-vinyl acetate (EVA) is a versatile material widely utilized across various industries for its exceptional properties, such as medical, electronics, marine, and solar sectors, etc. Known for its flexibility, resistance, and adaptability, EVA finds applications in different sectors, contributing to its widespread usage.

- Footwear manufacturing: EVA is a key material in the footwear industry, particularly in the production of shoe soles. Its cushioning properties, slip resistance, and durability make it an ideal material for creating comfortable and long-lasting footwear.

- Automotive components: In the automotive sector, EVA is employed in crafting components like bumpers and molded parts. Its ability to withstand harsh environmental conditions, chemicals, and oils makes it a reliable choice for such applications.

- Water toys and sports equipment: The flexibility of EVA makes it perfect for manufacturing flexible rubbery water toys and sports equipment. Whether in the form of padding for helmets, protective gear, or water-related recreational items, EVA's properties contribute to safety and performance.

- Flexible product packaging: EVA is utilized in the packaging industry for creating foam inserts that protect delicate items during transportation. Its cushioning and shock-absorbing capabilities make it an excellent choice for safeguarding items from potential damage.

- Medical industry: EVA plays a crucial role in the medical sector, where it is used to manufacture various devices such as tubing, catheters, and surgical instruments. Its resistance to chemicals and flexibility are advantageous in medical applications.

- Electronics and marine industries: In the electronics sector, EVA is used for heat and sound insulation applications. Its protective and insulating properties make it very useful in the shipping industry, contributing to the durability and safety of electronic equipment.

- Solar panels: The solar industry benefits from EVA's protective properties, as it is used in solar panels to shield solar cells. EVA contributes to the longevity and efficiency of solar energy systems.

- Adhesives and sealants: EVA's bonding properties make it suitable for formulating adhesives and sealants. EVA has good adhesive properties, especially for a variety of materials such as wood, paper, fabric, and plastic. In the construction industry, EVA is often used to seal cracks, crevices, or corners, such as when sealing between windows and door frames or incorporated into waterproof sealing materials.

EVA transparency for packaging and covering

In essence, EVA is the right choice for cushioning, shock absorption, and comfort products, widely used in industries ranging from footwear and packaging to healthcare and more. position. EVA's versatility and safety continue to make it the preferred material for the production of a wide range of products.

4. Conclusion

In conclusion, the remarkable characteristics of EVA resin, from its flexibility and durability to its wide-ranging applications, underscore its significance in modern industries. Whether providing comfort in footwear, resilience in automotive components, or versatility in packaging, Ethylene-vinyl acetate continues to redefine possibilities. This copolymer's adaptability and reliability exemplify its enduring role in shaping the innovative and practical solutions we encounter daily across multiple sectors.

5. About EuroPlas

With 7 factories located in 6 Vietnam's provinces and one in Egypt, EuroPlas has proven itself to be the world's leading manufacturer of filler masterbatch, EuroPlas has affirmed its pioneering position in providing comprehensive solutions for the plastics industry. By constantly innovating and developing, EuroPlas focuses on meeting the increasingly diverse needs of the market.

Stay connected with us and frequently visit our blog for the latest updates on industrial plastic products. EuroPlas is committed to keeping you informed with the latest insights to enhance your understanding of industrial materials.