Are you curious to learn more about this fascinating material? Read on to find out how glow-in-the-dark plastic works, what different types there are, and some of its most innovative uses.

Glow-in-the-dark plastic is created by combining molten plastic with phosphorescent material. The material has two types: organic and inorganic.

Phosphorescent materials glow in the dark after absorbing light through a process known as "excited state absorption." When a phosphorescent material absorbs light, it excites the electrons in its atoms to a higher energy level. These electrons then return to their ground state, releasing surplus energy as photons of light.

The time required for a phosphorescent substance to discharge its energy varies depending on the material. Some phosphorescent materials emit energy immediately, whereas others emit energy slowly over hours or even days.

The phosphorescent powder in glow-in-the-dark plastic has been modified to slowly release its energy, allowing it to shine in the dark for an extended period of time.

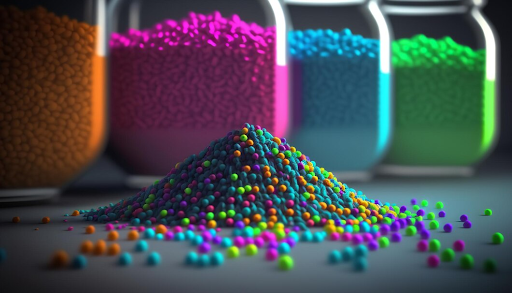

Picture 2. Glow-in-the-dark plastic is also used to develop innovative products that were previously inconceivable.

Consider a trampoline with a ball on it. The trampoline is the phosphorescent powder, and the ball is the electrons.

The ball gathers energy from your palm and rises into the air when you bounce it. The energy received when a bounce is released when the ball falls back down.

Phosphorescent materials behave similarly. When they absorb light, their electrons become more energetic.

When the electrons return to their ground state, the energy that they absorb as photons of light is released.

3. Types of glow-in-the-dark plastic

Picture 3. Inorganic phosphors are commonly used in the production of glow-in-the-dark plastic.

They come in a variety of forms, each with its own set of features. Some phosphors emit only one color, while others emit a wide range of colors. Some phosphors glow for a short time, while others glow for a long time.

3.1. Strontium aluminate (SrAl2O4)

One of the most common varieties of glow-in-the-dark plastic is strontium aluminate. It is a bright and long-lasting material that may be used to manufacture a wide range of products, including toys, signage, and safety equipment.

Glow-in-the-dark plastic manufactured with strontium aluminate can be up to ten times brighter than zinc sulfide glow-in-the-dark plastic.

3.2. Zinc sulfide (ZnS)

Another common sort of glow-in-the-dark plastic is zinc sulfide. It has a lower brightness than strontium aluminate but is more affordable and easier to synthesize.

Zinc sulfide is often used in low-cost applications, such as disposable glow-in-the-dark goods.

3.3. Calcium aluminate (CaAl2O4)

While the two types mentioned above are quite widespread, calcium aluminate is a newer sort of glow-in-the-dark plastic that is gaining popularity. It is brighter, more durable, and more environmentally friendly than strontium aluminate. High-end items, such as glow-in-the-dark watches and jewelry, frequently contain calcium aluminate.

3.4. Europium-doped strontium titanate (Eu:SrTiO3)

A form of glow-in-the-dark plastic notable for its lengthy afterglow is europium-doped strontium titanate. It can keep glowing for hours or even days after being exposed to light. Europium-doped strontium titanate is frequently used in applications requiring long-term illumination, such as emergency exit signs and safety markers.

Aside from these basic varieties of glow-in-the-dark plastic, there are several others available, including photoluminescent plastic, electroluminescent plastic, and chemiluminescent plastic.

Phosphorus, the main element in glow-in-the-dark plastic, was discovered by German physician Hennig Brand in

1669. He named the new element "phos" (light) and "phoros" (bearing), after the Greek words for light and bearing.

4. Applications of glow-in-the-dark plastic

Picture 4. Glow-in-the-dark plastic is now employed in a wide range of items, including toys

4.1. Safety products

Glow-in-the-dark material is frequently used in safety items to increase visibility in low- or no-light settings. Exit signs, life jackets, and glow sticks are examples of such items.

4.2. Toys and games

Glow-in-the-dark plastic is a popular material for toys and games, such as glow-in-the-dark balls, frisbees, and building blocks. It can also be used for fabricating glow-in-the-dark versions of classic games like chess and checkers.

4.3. Home décor

Glow-in-the-dark lamps can completely transform a space, providing a soft and ethereal glow that is both inviting and calming, while also adding a touch of whimsy and enchantment. They are also an excellent method to create a personalized and friendly environment.

Glow-in-the-dark wall art is another option. Adding distinctive and eye-catching wall art may transform any area into a lovely oasis.

4.4. Industrial applications

Plastic that glows in the dark is also employed in industrial applications. It can be used to create glow-in-the-dark markings on electrical equipment, for example, to make it more apparent in low-light or no-light settings. Or, in dangerous areas, glow-in-the-dark signage and labeling.

4.5. Novelties

Glow-in-the-dark jewelry may lend a whimsical and playful element to any outfit, making it ideal for special occasions or festivals. Glow-in-the-dark apparel is a fun way to display your particular style while also standing out from the crowd. Glow-in-the-dark beauty products can be used to achieve a range of styles, from subtle to strong and dramatic.

Glow-in-the-dark plastic is a versatile material that can be used to produce a range of novelty things, whether you're searching for a fun and festive accessory or a means to create a unique look.

5. Finding ways to tackle environmental impact of glow-in-the-dark plastic

Picture 5. Some glow-in-the-dark plastics contain heavy metals, which can contaminate soil and water.

5.1. Reduce consumption

One of the best ways to reduce the environmental impact of glow-in-the-dark plastic is to use less of it. We can do this by buying fewer products that are made with glow-in-the-dark plastic, and by repairing or reusing glow-in-the-dark products whenever possible.

For example, instead of buying a new glow-in-the-dark phone case, could you fix your current one? Or if you have a glow-in-the-dark toy that's broken, could you try to glue it back together?

5.2. Develop new recycling technologies

Another way to reduce the environmental impact of glow-in-the-dark plastic is to develop new recycling technologies that can effectively remove the phosphorescent materials from the plastic. This would allow glow-in-the-dark plastic to be recycled and reused, instead of being sent to landfills.

Researchers are working on this problem, but there's still no commercial-scale solution yet. In the meantime, we can do our part by supporting companies that are developing sustainable glow-in-the-dark plastics.

5.3. Develop biodegradable glow-in-the-dark plastics

Researchers are also developing new types of glow-in-the-dark plastics that are made from biodegradable materials. These plastics would break down naturally in the environment, which would help to reduce the amount of glow-in-the-dark plastic that ends up in landfills.

This is a promising area of research, but it's still early days. It's not clear yet when biodegradable glow-in-the-dark plastics will be widely available.

5.4. Support sustainable glow-in-the-dark plastics

We can also support the development and commercialization of sustainable glow-in-the-dark plastics. This includes buying products that are made with sustainable glow-in-the-dark plastics, and donating to companies that are developing these materials.

One way to find products made with sustainable glow-in-the-dark plastics is to look for the "biodegradable" or "compostable" label. You can also try to find companies that are committed to sustainability.

6. Conclusion

Glow-in-the-dark plastic is a relatively new material, but it has already had a major impact on our world. It has rendered our homes, workplaces, and public spaces safer and more aesthetically pleasing. It has also enabled the development of innovative products that were previously inconceivable.

Looking to learn more about sustainable plastics and innovative plastic solutions? Visit the

EuroPlas website to discover our latest research and development.