Nylon 11 (PA 11) is a type of thermoplastic resin belonging to the polyamide family. It is produced from renewable resources and possesses numerous superior properties. Nylon 11 is a versatile material that can be utilized across a wide range of applications. It stands as a favorable choice for applications demanding high strength, chemical and heat resistance, as well as sustainability. Let EuroPlas delve into the details of Nylon 11's attributes, history, and applications through the following article.

1. What is Nylon 11?

Nylon 11 or Polyamide 11 (PA 11) is a type of polyamide produced from petroleum oil. It possesses several outstanding properties compared to other synthetic plastics, including high strength, corrosion resistance, elasticity, and high tensile strength.

Nylon 11 is utilized in various applications, including the production of fibers, fabrics, films, automotive components, medical equipment, and other consumer products.

.jpg)

What is Nylon 11?

Read more: What is nylon? All about its properties and common uses

2. Nylon 11’s history

In 1938 the research director of Thann & Joseph Zeltner of Mulhouse was the first to propose the idea of Nylon 11, suggested in the works of Wallace Carothers. What & Mulhouse was already involved in the conversion of castor oil into 10-undecanoic acid, which was finally converted into the first batch of 11-aminoundecanoic acid in 1940 with the help of collaborators Michel Genas and Marcel Kastner.

By 1944 Kastner had sufficiently perfected the monomer process and in 1947 the first patents for Nylon 11 were filed. The first nylon 11 yarn was developed in 1950 and full industrial production began with the opening of the Marseilles manufacturing facility in 1955, which remains the sole producer of 11-aminoundecanoic acid to date.

- The 1960s marked the diversification of Nylon 11 applications. This type of material began to emerge in the automotive and medical device sectors.

- In the 1970s, Nylon 11's presence grew in daily life through its utilization in household products and sports equipment.

- The 1980s saw Nylon 11's introduction to the aerospace and space industries.

- By the 1990s, with technological advancements, Nylon 11 found its way into the realms of electronics and optics.

- In the 2000s, Nylon 11 started to be widely employed in applications related to energy and environmental protection.

- Up to the present day, Nylon 11 has demonstrated its diversity and flexibility in applications. With its capacity for strength, resistance to abrasion, and insulating properties, Nylon 11 continues to drive industrial development and meet societal needs.

.jpg)

Nylon 11’s history

3. The Properties of Polyamide 11

Nylon 11 (PA 11) is a type of bio-based plastic, meaning it is produced from renewable sources, specifically petroleum oil. Nylon 11 possesses several notable characteristics, including:

- High hardness, with excellent resistance to deformation and impact.

- High heat resistance, capable of withstanding temperatures up to 150°C.

- Excellent chemical resistance, impervious to corrosion from acid, base, and salt solutions.

- Color stability, resistant to fading over time.

- High recyclability, ease of processing, and versatility in methods such as molding, injection molding, and weaving.

- Environmentally friendly, recyclable, and reusable.

- Good water and oil resistance.

- Low electrical and thermal conductivity.

.jpg)

The Properties of Polyamide 11

4. Advantages and Disadvantages of Nylon 11

Nylon 11 boasts numerous outstanding advantages:

- It possesses higher durability compared to other synthetic plastics, including both nylon 6 and nylon 66. Nylon 11 can withstand high tensile, compressive, and shear forces.

- With its high elasticity, it can endure external impacts without deformation.

- It can handle temperatures up to 150°C, making it suitable for a variety of applications, including those with stringent temperature requirements.

- It resists various chemicals, including acids, bases, and solvents.

- Its high abrasion resistance allows it to excel in demanding durability applications.

- It remains functional in low temperatures down to -40°C, ideal for cold temperature-sensitive applications.

- Its high fire resistance makes it suitable for high-safety applications.

- It's recyclable, contributing to environmental sustainability.

However, Nylon 11 also exhibits several drawbacks:

- Its cost is higher compared to other synthetic plastics like nylon 6 and nylon 66.

- It has high water absorption, leading to swelling and distortion on contact with water.

- Its thermal conductivity is low, making it unsuitable for applications requiring high heat conduction, such as kitchen utensils.

- Its electrical conductivity is poor, making it unfit for applications requiring high electrical conductivity, like electronic devices.

- Its mechanical strength is lower compared to other synthetic plastics like nylon 6 and nylon 66.

Overall, Nylon 11 is a synthetic plastic with multiple advantages, but it also comes with a few disadvantages. Depending on specific applications, you can consider using Nylon 11 or other synthetic plastics.

Advantages and Disadvantages of Nylon 11

5. Applications of Nylon 11

Nylon 11 finds application across various domains, including:

- Textile Industry: Nylon 11 is utilized in producing clothing, footwear, hats, bags, and other textile products. It's also used in medical products like surgical gloves and tubing.

- Automotive: Nylon 11 is employed in crafting automotive components such as gears, shafts, and drivetrain parts. It's also used in aerospace and marine applications.

- Electrical and Electronics: Nylon 11 is used in creating electrical and electronic parts, such as computer casings, cables, and wires. It's also utilized in medical devices like patient monitors and surgical equipment.

- Construction: Nylon 11 contributes to construction materials like roofing panels, water pipes, and doors. It's also present in sporting goods like golf clubs, tennis rackets, and balls.

- Household Goods: Nylon 11 is involved in manufacturing household items like pots, pans, and kitchen utensils. It's also used in toys, such as dolls, toy cars, and sports equipment.

- Aviation: Nylon 11 is essential in producing aircraft parts like wings, fuselages, and tails. It's also used in creating engine components like gears, shafts, and other drivetrain parts.

- Medical: Nylon 11 is employed in crafting medical devices such as syringes, needles, and other surgical tools. It's also used in producing parts for medical equipment like respirators, blood filters, and other devices.

Nylon 11 is a versatile plastic with applications spanning various industries. It's highly regarded for its durability, hardness, weather resistance, and thermal capabilities. Nylon 11 is also recyclable and environmentally friendly.

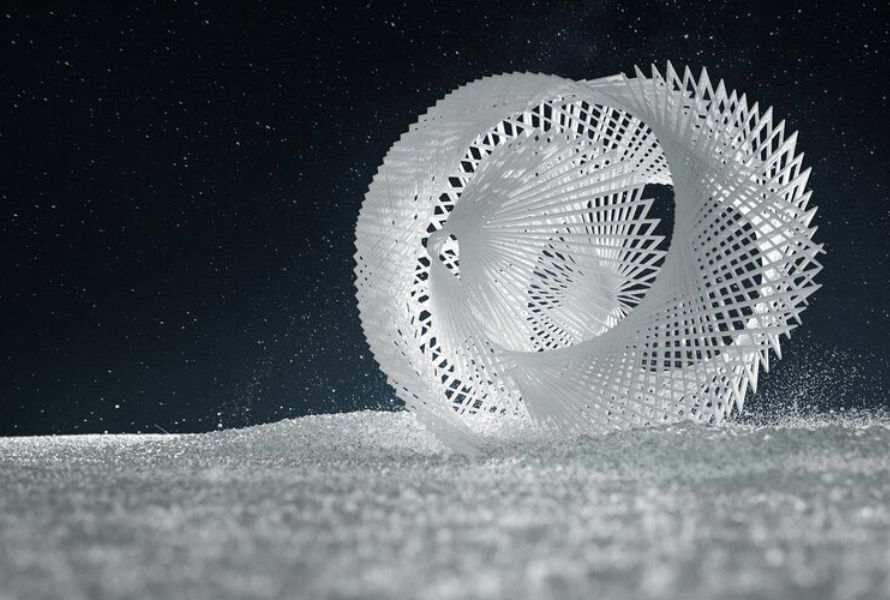

.jpg)

Applications of Nylon 11

6. EuroPlas - Trusted Partner for Engineering plastic compound

EuroPlas specializes in providing top-notch engineering plastic compounds. As a leading company in Vietnam, we offer a wide range of high-quality plastic compounds that cater to various industries, including automotive, electronics, construction, and packaging. Here are some advantages of EuroPlas' plastic compound products:

- High Quality: Our plastic compounds are crafted from virgin plastic materials and premium additives, ensuring durability, hardness, heat resistance, and excellent weather resistance. We also offer specialized compounds, such as flame-retardant, conductive, and anti-static plastics.

- Diversity: EuroPlas provides a diverse range of plastic compounds, tailored to meet the unique demands of various industries.

- Competitive Pricing: EuroPlas is committed to supplying customers with high-quality plastic compounds at competitive prices.

- Excellent Customer Service: Our team of skilled engineers and workers are ready to assist and guide customers in selecting the most suitable plastic compound for their needs.

.jpg)

EuroPlas specializes in providing top-notch engineering plastic compound

If you're in search of a reputable plastic compound supplier, look no further than EuroPlas. Contact us today for expert guidance and support in choosing the right plastic compound to meet your requirements.