When it comes to versatile plastic materials that are widely applicable across various industries, it is impossible not to mention PPE plastic. Due to its corrosion resistance and ability to withstand chemicals, PPE plastic has become a lifesaver for industrial equipment, ranging from pump valve systems, electronic components, automotive parts to medical devices. With continuous advancements, PPE plastic has become an optimal choice for businesses and manufacturers. Let

EuroPlas guide you through the detailed information about this plastic material in the article below!

Table of contents

1. What is PPE plastic?

2. PPE plastic’s properties

3. Applications of PPE plastic

4. About European Plastic Company

1. What is PPE plastic?

What is PPE plastic?

What is PPE plastic?

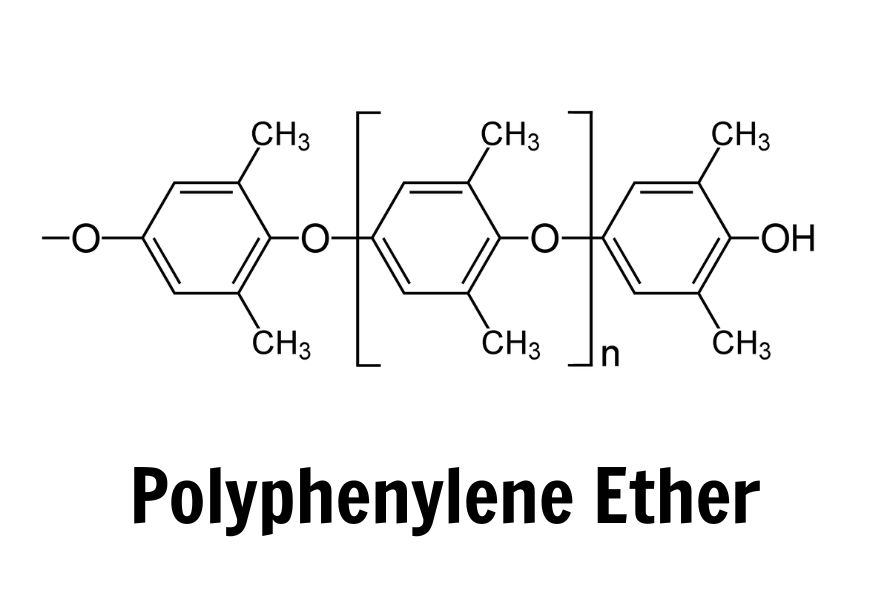

PPE, also known as polyphenylene ether, is a high-quality thermoplastic material that was initially discovered by Allan Hay in 1959 and quickly made its way into the commercial market with the guidance of General Electric just a year later. In certain instances, PPE plastic may also be recognized by its alternative names, such as PPO (Polyphenylene oxide) or the comprehensive chemical designation of Poly(2,6-dimethyl-1,4-phenylene ether).

PPE is widely recognized as an engineering polymer with exceptional heat resistance, excellent dimensional stability, and impressive mechanical properties. These remarkable characteristics have led to its widespread use across various industries, particularly in manufacturing industries.

Overall, PPE is a versatile material that combines excellent mechanical, thermal, chemical, and electrical properties. Let's explore in more detail properties and applications of PPE plastic in the following sections of the article with EuroPlas.

2. PPE plastic’s properties

Properties of PPE plastic

Properties of PPE plastic

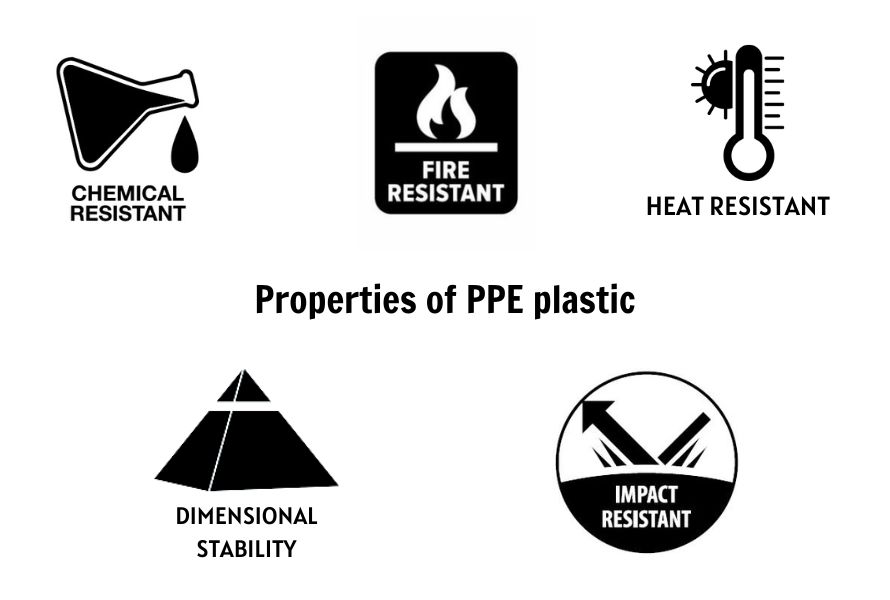

Gaining a comprehensive understanding of the properties of PPE plastic allows you to fully exploit the advantages it offers. Firstly, PPE plastic stands out for its exceptional heat resistance, enabling it to survive high-temperature environments without compromising its original mechanical properties.

Secondly, PPE plastic possesses remarkable chemical resistance, withstanding acids, bases, and solvents. In addition, PPE plastic maintains dimensional stability, ensuring the consistency of its shape and size despite different conditions.

Furthermore, PPE plastic is recognized for its fire-resistant properties, ensuring enhanced safety in fire-related situations. Moreover, it serves as an ideal insulating material in the field of electronic industry.

Additionally, its exceptional impact resistance further establishes PPE plastic as a highly durable material capable of withstanding external forces. These outstanding attributes make PPE plastic stand out as a flexible, reliable, and valuable material for numerous industries.

However, PPE plastic also presents certain drawbacks. Firstly, PPE plastic exhibits high viscosity, which can pose challenges during the processing and molding of plastic products using this material.Finally, the cost of PPE plastic can be considered a disadvantage. In comparison to other plastic materials, PPE carries a higher price, which may serve as a barrier for applications with limited budgets.

3. Applications of PPE plastic

PPE plastic finds its applications in various industries based on its exceptional characteristics and benefits. In the automotive and aerospace sectors, PPE is utilized for air intakes, valve covers, engine components, and under-the-hood parts due to its impressive heat resistance, dimensional stability, size, and resistance to chemicals.

Application of PPE Plastic in Engine Components

Application of PPE Plastic in Engine Components

Moreover, in the electrical and electronics fields, PPE plastic is commonly employed in switchgear, circuit breakers, connectors, and socket covers. Its flame retardant and insulating properties also make it suitable for use in household products, dishwasher components, and various kitchen appliances.

The durability and ability to withstand chemicals makes PPE suitable for handling corrosive liquids found in pumps, valves, and filtration systems in industrial equipment. Furthermore, PPE is crucial in manufacturing surgical instruments, IV connectors, and diagnostic equipment that enhance the quality of healthcare services.

PPE plastic has demonstrated its versatility and dependability across numerous industries, showcasing its wide range of applications. In addition, the application of PPE plastic is expanding with new advances, establishing it as the ideal option for businesses and manufacturers.

4. About European Plastic Company

Bioplastic Compound

Bioplastic Compound

BiONext is a brand of biodegradable engineering plastic that is manufactured using a base of biodegradable resin combined with appropriate additives, depending on the requirements of the final product. With its diverse properties, BiONext is widely applied in various fields, including the production of biodegradable film, food packaging, agricultural films, injection molding, and the manufacturing of utensils, plates, sheets, and more.

Color Masterbatch

Color Masterbatch

The method of coloring through color masterbatch is a popular technique for achieving color effects in plastics. This product is created by blending color pigments and suitable additives into a base of conventional resin, and it is supplied in the form of masterbatch pellets. EuroPlas offers a range of high-quality color pellets, ensuring precise, stable, and durable colors for plastic products.

Plastic additives

Plastic additives

During the manufacturing and usage processes, plastics often face risks from the surrounding environment or the plastic material itself. To address this issue, EuroPlas currently offers a range of 11 essential additives including UV resistance, anti-aging properties, fire resistance, and anti-static properties. These additives are applied to enhance efficiency during the production process and improve the quality of the final products.

.jpg) Engineering Plastic Compound

Engineering Plastic Compound

Compound engineering plastics are widely used in various industries, especially in those that demand high technical proficiency such as automotive, motorcycles, household electrical appliances, electrical engineering, electronic components, and office equipment. EuroPlas products integrate multiple beneficial features, including chemical resistance, impact resistance, wear resistance, and the ability to adjust the structure easily to meet stringent technical requirements.

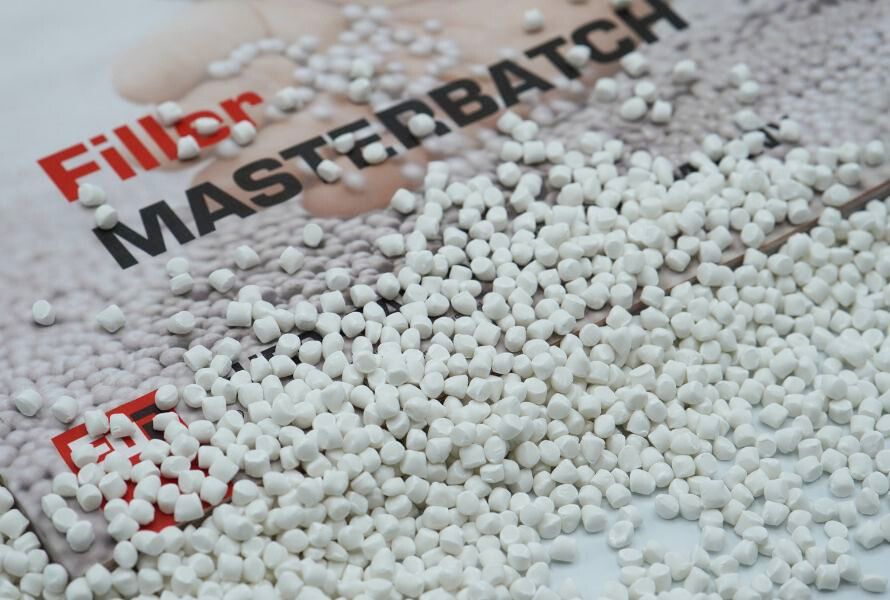

Filler masterbatch

Filler masterbatch

Filler masterbatch is a blend composed of traditional base plastics (such as PP, PE, HIPS) and CaCO3 stone powder, along with appropriate additives, encapsulated in masterbatch pellets. The primary purpose of filler masterbatch is to partially substitute virgin plastic. Moreover, filler masterbatch plays a crucial role in significantly reducing production costs while enhancing the competitiveness of the final product.

Bio filler

Bio filler

BiOMates is a special brand of plastic filler, created from biodegradable plastic and suitable additives depending on the desired end product. Bio filler not only possesses all the outstanding advantages of filler masterbatch, but it also has the ability to biodegrade within 12 months after use, promoting environmental friendliness.

At Europlas, we take pride in delivering top-notch plastic products that undergo meticulous processing for each component with exceptional precision. Our team of highly skilled experts is dedicated to providing unrivaled services, ensuring complete customer satisfaction.

Get in touch with us today to explore our wide range of products and discover the ideal plastic solution tailored to your specific needs.

You can find additional valuable information right here!