What does PVA stand for? PVA stands for polyvinyl alcohol. This is a synthetic polymer made from the polymerization of vinyl acetate.

It’s a water-soluble polymer, which means that it can dissolve in water, making it ideal for various applications, such as food packaging, adhesives, and personal care products.

PVA plastic is a truly revolutionary material that is changing the way we live and work. Learn more about its unique properties and applications in this article.

1. What is PVA plastic?

1.1. What is polyvinyl alcohol?

Picture 1. PVA plastic: The versatile and sustainable material

Polyvinyl alcohol (PVA) plastic is a water-soluble synthetic polymer made from vinyl acetate. It is a white, odorless, and non-toxic solid with a slightly sweet taste. PVA is soluble in water and hot alcohols, but insoluble in common organic solvents.

PVA is a good film former and has good adhesion to a variety of surfaces. PVA plastic is a versatile and sustainable material with a wide range of applications. It is biodegradable, edible, and can be used in 3D printing and self-healing materials.

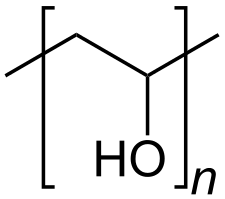

1.2. Structure of polyvinyl alcohol

PVA plastic is a type of plastic made up of long chains of repeating units called vinyl alcohol units. These units are connected to each other by carbon-carbon bonds, forming a linear or branched structure. The structure of PVA plastic affects its properties, such as strength, heat resistance, flexibility, and impact resistance.

Imagine a string of beads, where each bead represents a vinyl alcohol unit. The beads can be connected to each other in a straight line (linear structure) or in a branching pattern (branched structure).

The way the beads are connected affects the properties of the string of beads. For example, a straight line of beads is stronger and more rigid than a branching pattern of beads.

In the same way, the structure of PVA plastic affects its properties. Linear PVA plastic is stronger and more heat resistant than branched PVA plastic. However, branched PVA plastic is more flexible and impact resistant than linear PVA plastic.

Picture 2. PVA plastic molecule structure

1.3. Properties of PVA plastic

PVA plastic is a biodegradable, edible, and versatile material with a wide range of applications.

- Biodegradability: PVA plastic can be broken down by microorganisms into natural substances, making it a more sustainable choice than some other types of plastics.

- Edibility: PVA plastic is edible because it is made from vinyl alcohol, a naturally occurring substance found in many plants. PVA could be used to create edible capsules that contain vitamins, minerals, or other supplements.

- Versatility: PVA plastic can be used in a wide range of applications, including food packaging, personal care products, 3D printing, and self-healing materials.

Read more about biodegradable plastics: What are biodegradable plastics?

2. Applications of PVA plastic

2.1. Laundry and dish detergent pods

Picture 3. PVA plastic is the most common plastic used in laundry and dish detergent pods

The first laundry detergent pods were introduced in the United States in 2012. Laundry and dish detergent pods are now one of the fastest-growing segments of the detergent market.

PVA plastic is the most common type of plastic used in laundry and dish detergent pods by its water-soluble and biodegradable. This means that the pods dissolve quickly in water, releasing the detergent inside, and the PVA plastic itself breaks down over time, reducing waste.

PVA plastic also helps to keep the detergent pods from sticking together.

2.2. Food packaging

Picture 4. PVA plastic edible films and wraps can help to keep food fresh

A study by the Food and Agriculture Organization of the United Nations found that PVA is used as a coating, binder, sealing and surface finishing agent in food products such as dairy-based desserts, confectionery and cereal products and dietary supplement tablets, in the range of 0.2–1.8% by weight.

One of the most innovative and exciting applications of PVA plastic is in edible food packaging. Edible films and wraps made from PVA plastic can help to keep food fresh and reduce waste. These products can be composted after use, which makes them a more sustainable option than traditional food packaging made from petroleum-based plastics.

PVA plastic is a promising material for food packaging. It is safe, sustainable, and versatile. As the technology continues to develop, we can expect to see PVA plastic used in even more innovative and sustainable food packaging applications in the future.

2.3. Medical devices

PVA plastic is used in medical devices because it is biocompatible and biodegradable. This means that it is compatible with the human body and will eventually break down over time.

PVA plastic is used to make a variety of medical devices, such as contact lenses, sutures, and bandages. It enables medical devices more comfort, efficacy, and invasiveness compared to traditional counterparts.

2.4. Textiles

Picture 5. Polyvinyl alcohol is a good choice for fabrics and products.

PVA plastic is a versatile material that can be used in a variety of textile applications. It is water-soluble, biodegradable, and safe, making it a good choice for a variety of fabrics and products.

Researchers at the University of Manchester have developed a type of smart textile that uses PVA plastic to change color when exposed to different temperatures. This textile could be used to make clothing that is more comfortable and adaptive to the wearer's environment.

PVA plastic enables self-cleaning, moisture-wicking, and biodegradable textiles for clothing and diapers.

2.5. Adhesives

PVA plastic is a water-soluble and biodegradable adhesive that is used in a variety of applications, including wood glue, craft glue, and pressure-sensitive adhesives.

Compared to other types of adhesives, PVA plastic is more environmentally friendly and easier to clean up. It is also less toxic and safe for children, making it a popular choice for schools and other educational settings.

2.6. Paints and coatings

Compared to traditional oil-based paints, PVA plastic paints are better for indoor air quality because they emit lower levels of volatile organic compounds (VOCs). PVA plastic paints are also easier to clean up and less toxic.

In addition, PVA plastic can be used to create self-healing paints that can repair minor damage on their own. This makes PVA plastic paints a good choice for high-traffic areas, such as kitchens and bathrooms.

PVA plastic is increasingly being used to develop new and innovative paints and coatings. For example, researchers at the University of California, Berkeley have developed a type of PVA plastic paint that can change color in response to changes in temperature.

3. Challenges and opportunities of developing sustainable alternatives to PVA plastic

PVA plastic has a number of desirable properties, such as water solubility, film-forming ability, and non-toxicity. It can be difficult to find sustainable materials that have all of the same properties as PVA plastic.

There are still some challenges that need to be addressed in order to develop even more sustainable alternatives to PVA plastic. PVA plastic is a non-renewable resource and not always biodegradable. In some cases, PVA plastic can take hundreds of years to break down. This can lead to pollution and environmental damage.

Picture 6. Corn and sugarcane are renewable resources under development.

In demand for sustainable plastic products, EuroPlas has developed BiONext, a bioplastic compound that is a viable alternative to PVA plastic.

BiONext offers a number of advantages over PVA plastic. It is made from renewable resources, which helps to reduce greenhouse gas emissions and conserve fossil fuels.

This statement attests to EuroPlas' dedication to developing and manufacturing sustainable products. It demonstrates the company's commitment to environmental protection and human well-being.

4. Conclusion

PVA plastic is versatile and sustainable. It is safe for food contact, biodegradable, and can be used to create a variety of products, including food packaging, textiles, and adhesives.

To learn more about PVA plastic and other sustainable plastic products, please consult the EuroPlas knowledge base.