Are you looking for information about PVDF material? PVDF, short for Polyvinylidene fluoride, is a remarkable material known for its exceptional properties and wide range of applications. In this article, we will explore the key characteristics and uses of PVDF material for discovering why PVDF is highly regarded in industries such as chemical processing, aerospace, electronics, and more.

1. What is so special about PVDF material?

PVDF material stands out as a reliable solution for both chemical and mechanical applications. Whether facing corrosive chemicals or heavy physical loads, PVDF material consistently demonstrates its durability. This makes it a valuable material in industries that prioritize high performance.

- Chemical Resistance: PVDF material exhibits outstanding resistance to a wide range of chemicals, including acids, bases, solvents, and corrosive substances. It can withstand harsh chemical environments without degradation, making it invaluable in industries such as chemical processing, oil and gas, and semiconductor manufacturing.

- Mechanical Strength: PVDF material possesses robust mechanical strength and toughness. It has high tensile strength and excellent impact resistance, enabling it to withstand physical stress and harsh operating conditions. This durability makes it suitable for applications in construction, automotive, aerospace, and other industries that require materials capable of withstanding demanding mechanical loads.

Additionally, PVDF material is also notable for the following aspects:

- Thermal Stability: PVDF material offers impressive thermal stability. It has a high melting point and can maintain its properties over a wide temperature range. This characteristic allows it to withstand elevated temperatures without significant degradation, making it suitable for high-temperature applications such as wire and cable insulation, coatings, and components.

- Electrical Insulation: PVDF material is an effective electrical insulator. It provides reliable insulation for wires, cables, and electronic components, ensuring safe and efficient operation. Additionally, PVDF material exhibits piezoelectric properties, meaning it can generate an electrical charge when subjected to mechanical stress. This property opens up applications in sensors, actuators, transducers, and other devices that require the conversion of mechanical energy into electrical signals.

- Weather Resistance: PVDF material demonstrates exceptional weather resistance. It is highly resistant to weathering and UV radiation, maintaining its properties and appearance over extended periods. This makes it a preferred choice for outdoor applications such as architectural coatings, outdoor signage, roofing materials, and other applications that require long-term durability and protection against environmental elements.

- Versatility: PVDF material finds application in a wide range of industries and sectors. Its unique combination of properties makes it suitable for various applications. It is used in chemical processing equipment, wire and cable insulation, coatings, aerospace components, water treatment membranes, medical devices, automotive parts, and more. Its versatility and adaptability contribute to its special status as a material of choice in multiple industries.

PVDF material is highly valued for its exceptional properties, making it desirable for diverse applications.

2. About the PVDF material

PVDF material, short for Polyvinylidene fluoride, is a high-performance fluoropolymer derived from vinylidene fluoride monomers. It is known for its exceptional properties, which makes it applied in various industries due to its versatility and ability to withstand harsh conditions.

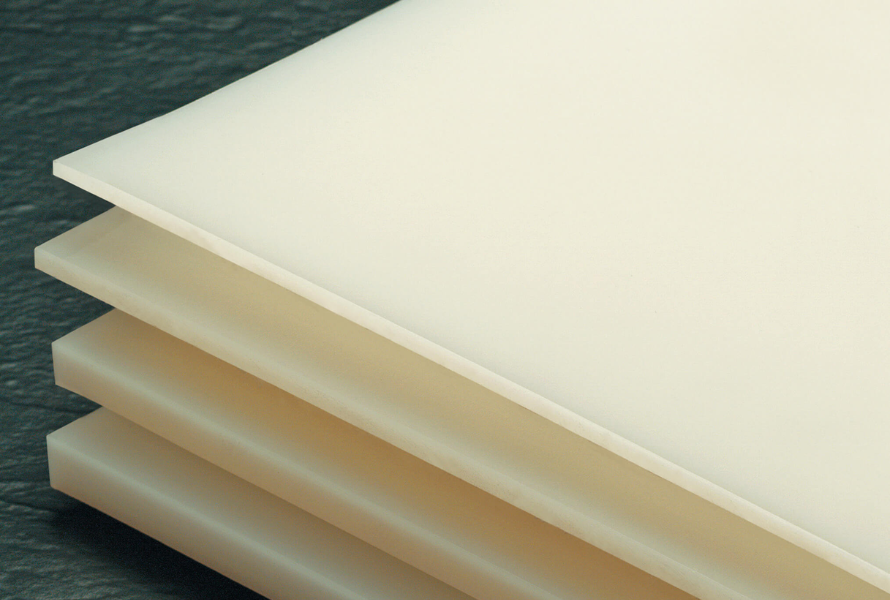

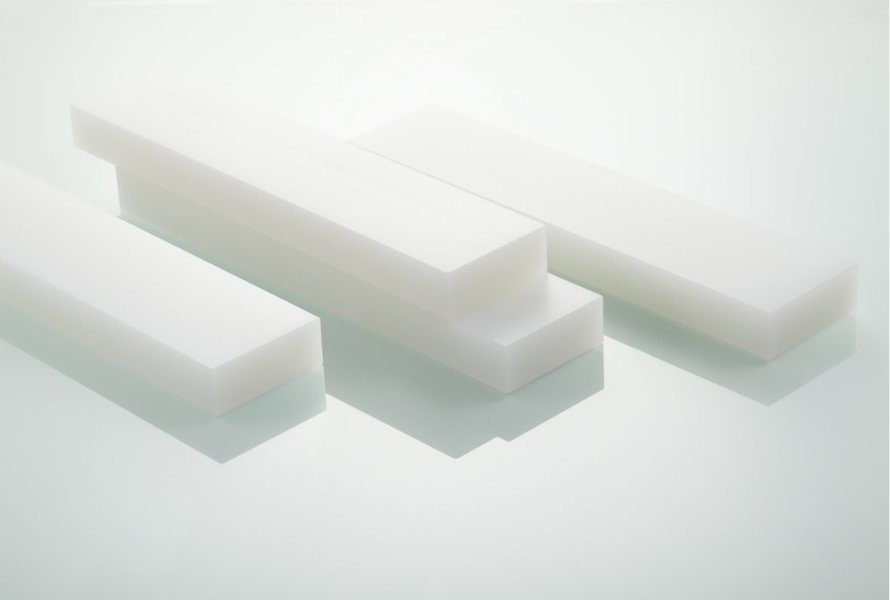

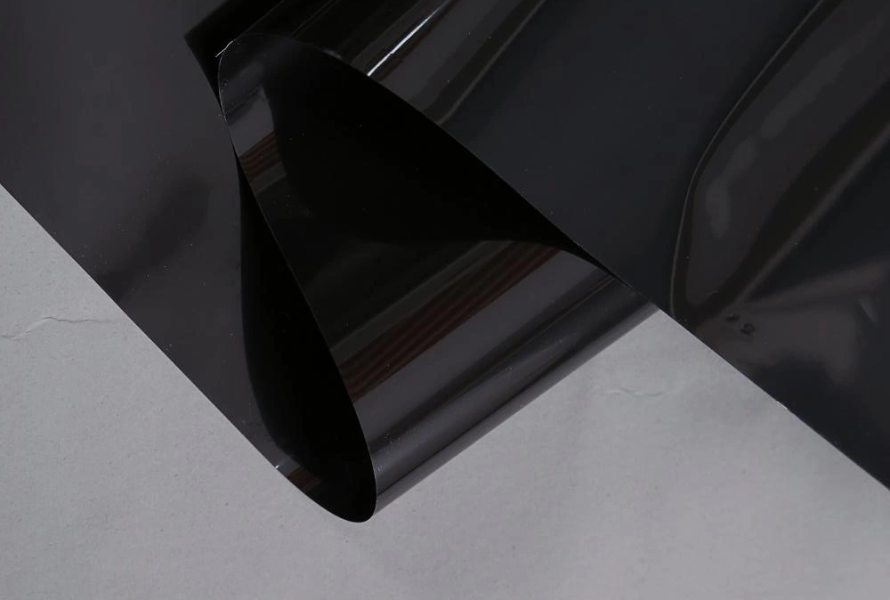

PVDF material is produced through a polymerization process using the monomer vinylidene fluoride (VDF). The VDF monomer is polymerized either through suspension or solution polymerization. After polymerization, the PVDF is precipitated, collected, and washed to remove impurities. It may undergo additional processing steps like drying and grinding. The resulting PVDF material is then formed into powder, pellets, film, or resin for various applications.

PVDF material's exceptional properties make it versatile and suitable for various industries and harsh conditions.

3. Applications of PVDF material

PVDF material finds numerous applications across various industries due to its exceptional properties. Here are some common applications of PVDF:

- Chemical Processing: PVDF's excellent chemical resistance makes it ideal for use in chemical processing equipment, pipes, valves, and fittings. It can withstand exposure to corrosive chemicals, acids, and solvents, ensuring the integrity and longevity of the equipment.

- Wire and Cable Insulation: PVDF's thermal stability and electrical insulation properties make it suitable for wire and cable insulation in industries such as telecommunications, electronics, and power transmission. It provides reliable insulation, even at high operating temperatures.

- Coatings and Paints: PVDF is widely used as a coating material due to its exceptional weather resistance, UV stability, and low surface energy. It is applied as a protective coating on architectural structures, outdoor signage, and automotive components, providing durability and protection against environmental factors.

- Aerospace and Defense: PVDF's combination of mechanical strength, chemical resistance, and thermal stability makes it valuable in the aerospace and defense industries. It is used in aircraft components, fuel lines, insulation, coatings, and radar domes due to its ability to withstand extreme conditions and stringent performance requirements.

- Oil and Gas: PVDF is utilized in the oil and gas industry for applications such as pipes, fittings, valves, and seals. Its chemical resistance ensures compatibility with various hydrocarbons, acids, and corrosive substances, making it suitable for offshore and onshore environments.

- Water Treatment: PVDF is employed in water treatment applications due to its resistance to chemicals and fouling. It is used in membranes for filtration, water purification systems, and desalination processes, ensuring efficient and reliable water treatment.

- Medical and Healthcare: PVDF's biocompatibility and sterilizability make it suitable for medical and healthcare applications. It is used in surgical implants, medical devices, drug delivery systems, and dental applications due to its compatibility with human tissues and ability to withstand sterilization processes.

- Electronics and Semiconductors: PVDF's electrical insulation properties and piezoelectricity make it valuable in electronics and semiconductor industries. It is used in capacitors, sensors, transducers, and piezoelectric devices for various applications, including pressure sensing, ultrasound imaging, and vibration detection.

- Architectural Membranes: PVDF is employed in architectural membranes for structures such as roofs, canopies, and facades. Its weather resistance, UV stability, and durability make it suitable for creating aesthetically pleasing and long-lasting architectural designs.

- Automotive Components: PVDF finds applications in the automotive industry for fuel and brake system components, hoses, gaskets, and seals. Its chemical resistance, mechanical strength, and thermal stability contribute to the reliability and durability of automotive parts.

PVDF material has extensive applications spanning multiple industries.

4. About EuroPlas

If you are looking for a reliable supplier of high-quality plastics, EuroPlas is the perfect choice. EuroPlas offers high-quality products and cost-effective plastic materials. With modern equipment and standard testing machines, EuroPlas ensures the highest-quality output. Our product range includes filler masterbatch, color masterbatch, additives, bio fillers, and bioplastics.

Please contact us right now to discuss our products or explore information about the plastic industry at our blog!