As the world seeks sustainable alternatives to traditional plastics, bioplastics have emerged as a promising solution. Understanding their life cycle is essential for evaluating their environmental impact and benefits. The following article will help you explore these essential things!

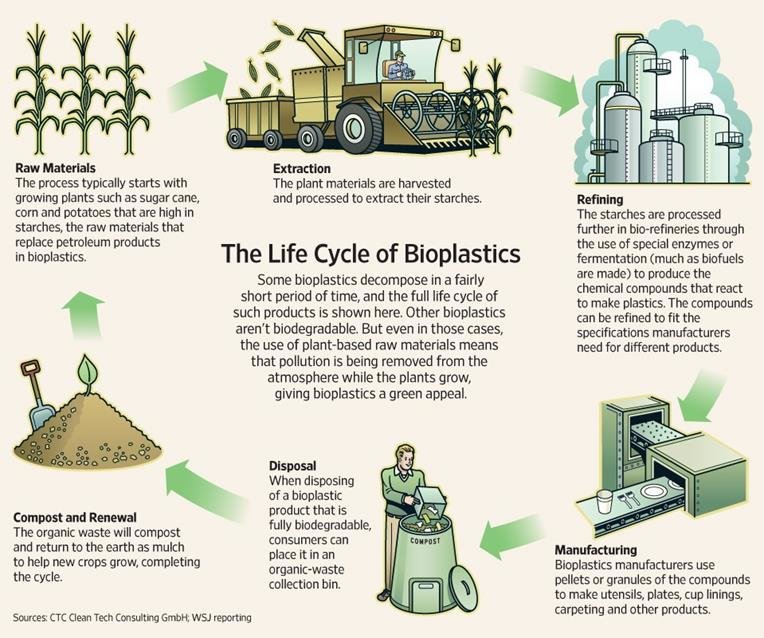

1. All Stages of A Bioplastic Life Cycle

The bioplastics life cycle involves several interconnected stages. Here’s a detailed overview:

Stage 1. Raw materials

The bioplastic life cycle begins with the sourcing of raw materials, which typically involves growing plants such as sugarcane, corn, or other starch-rich crops. These renewable resources serve as the foundation for bioplastic production.

Stage 2. Extraction

After that, the plants go through a process that allows the extraction of the starches. This extraction is important since it changes the plant biomass to polymers, which can easily be used. The effectiveness of this stage in the bioplastic life cycle may have a governing influence over the sustainability of the bioplastic.

Stage 3. Refining

In the refining stage, the extracted starches are given further processing in the formation of bioplastic resins. This shall be done by promoting special chemical reactions whereby the desired properties of the starches shall have been obtained and are fit for use.

Stage 4. Manufacturing

In the bioplastic production, they are formed into different products including packaging material, utensils and other consumable products. This stage in the bioplastic life cycle is aimed to provide evidence that bioplastic can provide similar performances as petroleum based plastic in many applications.

Stage 5. Disposal

Disposal in the bioplastic life cycle include:

- Biodegradable: Some bioplastics break down when subjected to given environments, give back nutrients to the soil, and decrease landfill.

- Compostable: Bioplastics can be recycled but a few are compostable, thereby decreasing the rate of organic material that is buried in landfills.

Stage 6. Compost and renewal

This is the last stage of the bioplastic life cycle. When bioplastics are disposed of and if there is composting, those will disintegrate completely and act as fertilizers for creating new plant growth, continuing a new bioplastic life cycle.

The bioplastic life cycle

2. Environmental Aspect of Each Stage

2.1. Raw materials

Agriculture of crops for the production of bioplastics may be advantageous to the environment in the following ways, or in some other ways may prove to be disadvantageous to the environment. Even though some renewable sources such as sugarcane have less impact on fossil fuels, they come with the same problem related to deforestation and loss of species.

2.2. Extraction

Starch separation from plants may be energy-costly and have chemical impacts on the environment's total balance. Compared to petroleum processes, it usually produces relatively lower carbon emissions. It can become more sustainable by utilizing effective energy management technologies and avoiding the use of toxic chemicals in extraction.

Plant starch extraction could be energy-intensive.

2.3. Refining

Converting extracted starch for bioplastic resins may produce some gases and waste products, especially where the energy used is from non-renewable sources. Through the utilization of renewable energy, the right techniques can in effect help refine the sustainability of the manufacturing firms and cut down environmental emissions.

2.4. Manufacturing

The manufacturing stage also puts forth greenhouse gas emissions and waste identically to other conventional plastics. Nevertheless, moving to bioplastics is a way out of the general problem of plastic pollution the world faces today. The use of cleaner production technologies and sustainable practices must be pursued if any negative environmental impacts resulting from activities of manufacturing bioplastics are to be reduced.

Bioplastic manufacturing processes can make some environmental impact.

2.5. Disposal

The disposal methods for bioplastics have advantages as well as disadvantages. Even though a host of them are biodegradable, wrong disposal leads to landfill waste. Education and support for composting and recycling structures are important strategies for reducing negative environmental impacts.

2.6. Compost and renewal

The final stage of bioplastics is as renewing to the environment as a bioplastic product. By composting, bioplastics break down completely and provide benefits for soil that support plant and animal life. Increasing the number of composting sites and initiatives is crucial if using compostable bioplastics is to generate optimal positive environmental impact.

3. Future Prospects of Bioplastic

3.1.Technological advancements

There are tremendous practices on the manufacturing and development of bioplastics, focusing on the improvement of their physical characteristics. It is believed that future development will lead to the creation of more durable, heat-resistant and mechanically stable bioplastics that will open more doors to industrial uses.

There will be more technical advancements for bioplastics in the future.

3.2. Economies of scale

With the increase in demand for bioplastics, the required production volumes will result in economies of scale. This shift can substantially cut costs and bring bioplastics closer to the cost of conventional plastics. Thus, cost reduction will help to increase the utilization by manufacturers and eventually, bring sustainable materials to common products.

3.3. Feedstock diversification

Investment in various feedstocks for producing bioplastics including agricultural waste, algae, and other renewables is likely to improve sustainability. This diversification makes it easy to avoid a situation where several crops are affected and it affects the entire supply chain. Thus, through different feedstocks, the bioplastic industry can help build a more sustainable feedstock supply chain.

3.4. Improved recycling techniques

In essence, the process of design for the effective recycling of bioplastics has to be developed and implemented to match the bioplastics. Enzymatic or chemical degradation processing methods are thought to dramatically provide work for recycling valves that were used in the production of bioplastics. Higher biodegradability of bioplastics will guarantee their recyclability and ability to fit the circular economy system to the maximum extent.

It is essential to improve the recycling techniques for bioplastics in the future.

4. Conclusion

Understanding the bioplastic life cycle is vital for assessing its environmental benefits and challenges. While bioplastics offer a more sustainable alternative to traditional plastics, careful consideration of each stage is necessary to ensure they fulfill their potential.

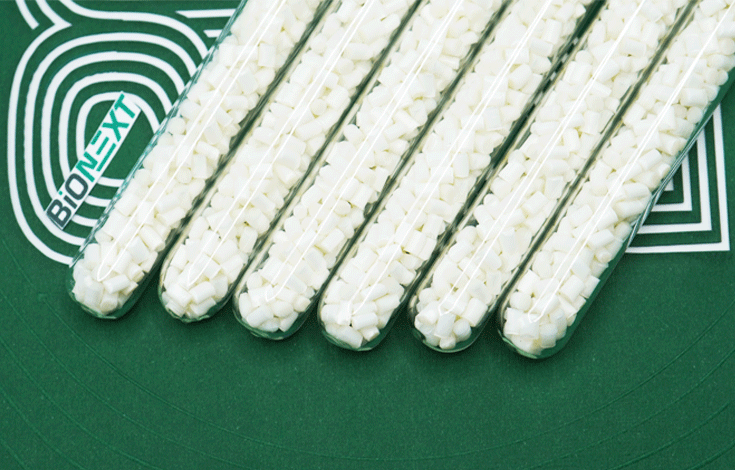

5. About EuroPlas’ Bioplastics

EuroPlas is at the forefront of bioplastic innovation, committed to creating high-quality, sustainable products. Our bioplastics, BiONext, are designed with the environment in mind, ensuring minimal impact throughout their life cycle, with the key features:

- Biodegradable within 12 months after use

- Outstanding mechanical properties

- Full functions in one material

- Tailor-made based on end-products' requirements

Contact us now for more support!