Are you wondering about the difference between plastic and rubber? Understanding their unique properties and applications can help you make informed choices. In this article, we delve into the key distinctions between plastic and rubber. From composition and physical properties to environmental impact and practical uses, we will provide a detailed comparison and help you make a better decision about these versatile materials.

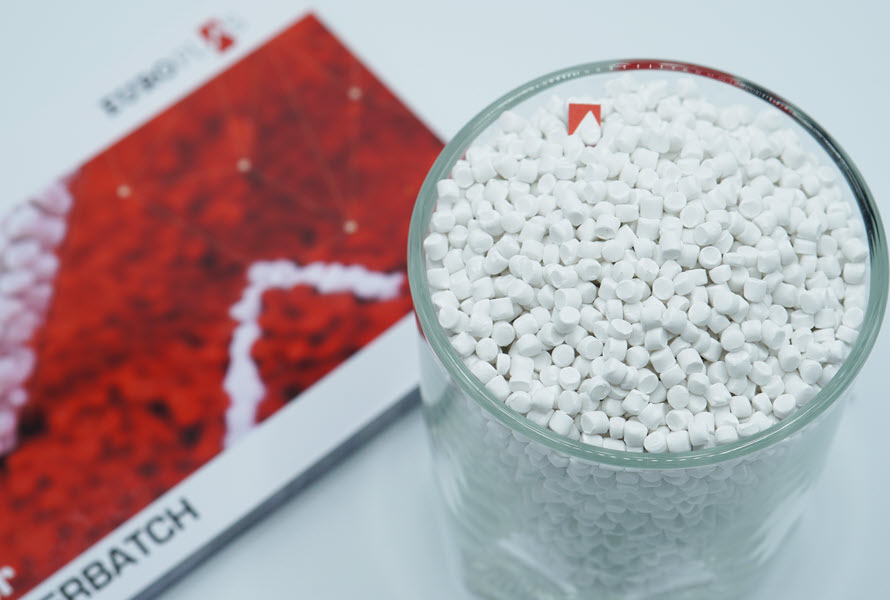

Read more: Masterbatch - definition, applications, market trends and more

1. Plastic and rubber

Plastic and rubber are two materials that have become incredibly ubiquitous in our modern world. They are present in a wide range of products and industries, influencing various aspects of our daily lives. Understanding the fundamental differences between plastic and rubber is essential to appreciate their unique properties and applications.

Plastic, as a synthetic material, has gained tremendous popularity due to its versatility, durability, and cost-effectiveness. It is used extensively in packaging, construction, automotive, electronics, and countless other industries. Plastic can be molded into different shapes and forms, offering flexibility and a wide range of physical properties.

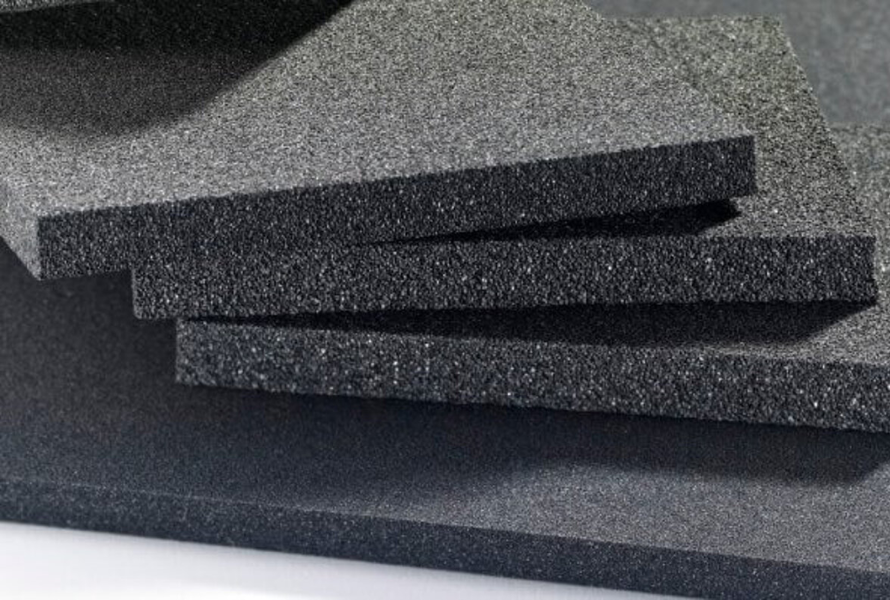

Rubber, on the other hand, is a material known for its elastic properties. It can be either natural or synthetic. Natural rubber is derived from the latex sap of specific plants, while synthetic rubber is manufactured from petroleum by-products. Rubber materials possess excellent elasticity, resilience, and resistance to abrasion. These properties make rubber ideal for applications such as tires, seals, gaskets, and various industrial and consumer products.

Plastic and rubber have become highly prevalent materials in our modern world.

2. Composition and Structure

2.1. Plastic

Plastic is a synthetic material composed of polymers, which are long chains of repeating molecular units. The composition of plastic can vary depending on the specific type, but it often includes additives, fillers, and reinforcing agents to enhance its properties. The molecular structure of plastic allows for flexibility in design, enabling manufacturers to create products with different shapes, sizes, and physical properties.

However, the environmental impact of plastic is a significant concern. Plastic waste takes a long time to degrade, with some types estimated to persist in the environment for hundreds of years. Improper disposal and inadequate waste management systems have led to widespread plastic pollution, particularly in oceans and waterways. Today, to address the issue of plastic pollution, there are several environmentally friendly plastics that have been developed. These types of plastics have high recyclability or are made from renewable sources, helping to minimize their impact on the environment.

In response to the problem of plastic pollution, various environmentally friendly plastics have been developed.

On the other hand, plastic offers several advantages over rubber in various applications. Here are some of the key advantages of plastic:

- Versatility: Plastic is highly versatile and can be molded into a wide range of shapes, sizes, and forms. It can be easily customized to meet specific design requirements and can be used in diverse industries such as packaging, construction, automotive, electronics, and consumer goods.

- Durability: Plastic is known for its durability and resistance to wear and tear. It can withstand harsh environmental conditions, including exposure to UV radiation, chemicals, and moisture. This durability makes plastic suitable for long-lasting applications, such as in building materials, automotive components, and electronic devices.

- Lightweight: Plastic is generally lighter in weight compared to rubber, which can be advantageous in various industries. The lightweight nature of plastic contributes to fuel efficiency in transportation, reduces material handling costs, and allows for easier assembly and installation.

- Cost-effectiveness: Plastic is often more cost-effective than rubber. It is relatively inexpensive to produce, and the production processes can be highly efficient. Additionally, plastic can be easily mass-produced, leading to lower costs for your projects.

- Design flexibility: The moldability of plastic allows for intricate and complex designs. Manufacturers can create products with specific features, textures, and geometries to meet functional and aesthetic requirements. Plastic also offers a wide range of color options, providing design flexibility and customization possibilities.

- Chemical resistance: Plastic exhibits excellent resistance to chemicals, including acids, alkalis, and solvents. This chemical resistance makes plastic suitable for applications where exposure to corrosive substances is a concern, such as in chemical storage containers and pipes.

- Electrical insulation: Many plastic materials possess good electrical insulation properties. They can effectively protect electrical components, making them widely used in the electrical and electronics industries.

2.2. Rubber

Rubber can be either natural or synthetic. Natural rubber is derived from the latex sap of certain plants, with the most common source being the Hevea brasiliensis tree. Synthetic rubber, on the other hand, is manufactured through chemical processes using petroleum byproducts. Rubber consists of long polymer chains with a high degree of cross-linking, which gives it its unique elastic properties. The structure of rubber allows it to stretch and return to its original shape, making it highly resilient and durable.

In terms of environmental impact, rubber, particularly natural rubber, is considered more environmentally friendly as it is derived from a renewable resource. However, the manufacturing processes involved in both natural and synthetic rubber production can have environmental impacts. These processes often generate waste materials, and release pollutants into the air and water. By adopting environmentally friendly practices, we can work towards minimizing the negative environmental consequences associated with rubber production and use.

Due to its renewable resource origin, natural rubber is often regarded as more environmentally friendly in terms of its impact compared to plastic.

3. Applications

Plastic's versatility enables its use in various industries and applications. Here are some examples of products that showcase the wide range of plastic applications:

- Bottles and Containers: Plastic bottles and containers are extensively used in the beverage, food, and personal care industries. They come in different shapes, sizes, and designs, providing convenience, durability, and effective product storage and distribution.

- PVC Pipes: Polyvinyl chloride (PVC) pipes are widely used in plumbing, drainage systems, and irrigation. PVC's durability, corrosion resistance, and cost-effectiveness make it a popular choice for these applications.

- Automotive Parts: Plastic is used in various automotive components, such as bumpers, dashboards, interior trims, and door panels. It offers weight reduction, design flexibility, and cost advantages, contributing to improved fuel efficiency and enhanced aesthetics.

- Packaging Films: Plastic films, such as polyethylene (PE) and polypropylene (PP) films, are used for packaging applications, including shrink wraps, stretch films, and food wraps. These films provide protection, preservation, and convenience in the packaging industry.

- Electrical Insulation: Plastic materials, such as polyethylene, polypropylene, and polyvinyl chloride, are used as electrical insulation in wires, cables, and electrical devices. Plastic's excellent electrical insulation properties help ensure safety and reliable performance in electrical systems.

- Medical Devices: Plastic is extensively used in the medical industry for a range of products, including syringes, IV tubes, surgical instruments, and prosthetics. Plastic's biocompatibility, sterilizability, and design versatility are critical factors in medical device manufacturing.

- Consumer Electronics: Plastic is widely used in the production of consumer electronics, including smartphones, laptops, tablets, and televisions. Plastic casings offer lightweight, durable, and customizable solutions for these devices.

- Toys: Plastic toys are popular due to their wide range of shapes, colors, and design possibilities. Plastic's durability, safety, and affordability make it an ideal material for toy manufacturing.

Meanwhile, rubber has a wide range of applications in industries such as automotive, footwear, and manufacturing. It is commonly used in tires, industrial seals and gaskets, footwear, conveyor belts, automotive components, medical equipment, sports and recreation products, and consumer goods. Rubber's properties, including elasticity, durability, and resistance to heat and chemicals, make it suitable for diverse uses. Whether it's providing grip on the road, sealing fluids, absorbing shock, or enhancing product flexibility, rubber plays a crucial role in numerous applications across different sectors.

Both rubber and plastic are popular in various industries such as automotive, medical devices,...

Moreover, understanding the differences between plastic and rubber is crucial for product development and selection of the appropriate material. Here's why it holds such significance:

- Material Properties: Plastic and rubber have distinct material properties that can significantly impact the performance and functionality of a product. Plastic is known for its durability, chemical resistance, and design flexibility, while rubber possesses elasticity, resilience, and excellent sealing properties. By understanding these differences, product designers can choose the material that best suits the specific requirements of their product.

- Mechanical Considerations: Plastic and rubber have different mechanical properties, such as stiffness, tensile strength, and elongation. These properties directly affect how the material will perform under different loads and conditions. For example, if a product requires flexibility and shock absorption, rubber may be the preferred choice. On the other hand, if the product needs structural strength and rigidity, plastic may be more suitable. Understanding these differences is crucial for ensuring that the product can withstand the intended usage and environmental conditions.

- Manufacturing Processes: Plastic and rubber have distinct manufacturing processes and considerations. Plastic can be easily molded, extruded, and formed into complex shapes using injection molding, blow molding, or other techniques. Rubber, on the other hand, often requires specialized processes. Understanding the manufacturing processes associated with each material is essential for optimizing production efficiency and achieving the desired product quality.

- Cost and Availability: The cost and availability of plastic and rubber can vary. Plastic materials are generally more cost-effective and widely available compared to rubber. By considering the cost and availability of both materials, product developers can make informed decisions that align with budgetary constraints and supply chain considerations.

- Environmental Impact: Plastic and rubber have different environmental impacts. Plastic is known for its non-biodegradability and potential for pollution, while natural rubber is derived from a renewable resource. Understanding the environmental implications of each material can help guide sustainable product development decisions and support environmentally conscious choices.

Differentiating between plastic and rubber is vital for effective product development and material selection.

4. Conclusion

In summary, plastic and rubber differ in composition, physical properties, applications, and environmental impact. While plastics are versatile but have significant environmental concerns, rubber is known for its elasticity and can be more environmentally friendly when derived from renewable sources. Both materials have their unique characteristics and play essential roles in various industries and everyday products.

If you are in search of a reliable source for high-quality plastic materials, look no further than EuroPlas. We specialize in a diverse range of plastics, particularly in environmentally safe bioplastics. Don't hesitate to contact us directly to discuss our products or view our blog for the latest updates in the plastic industry.