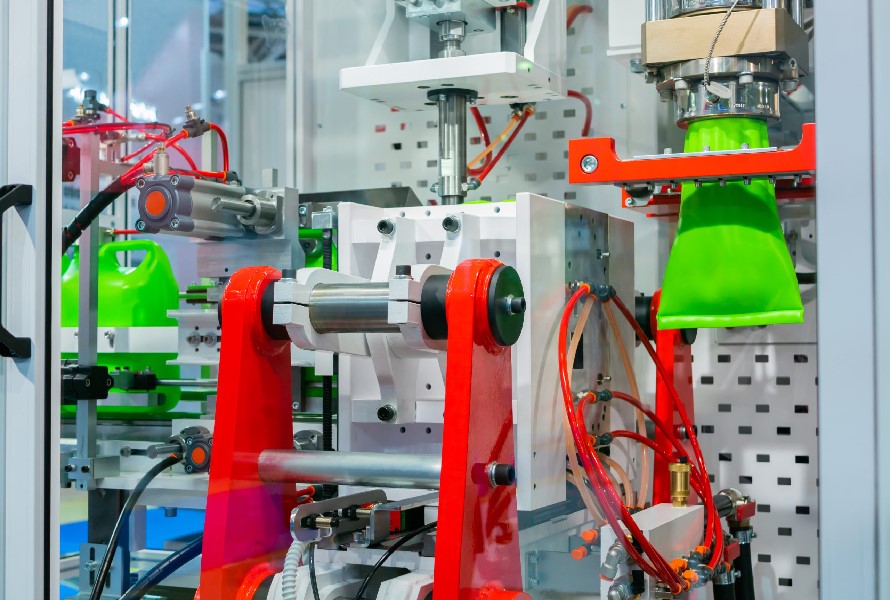

Blow molding is a type of plastic forming technique used to create hollow plastic items from thermoplastic materials. It uses heated, liquid material that is compressed and forced into a mold cavity, just like other molding techniques. However, the method is a unique kind of molding that makes use of the characteristics of conventional glassblowing.

Blow molding is widely used in various industries. Let's dig into this article to understand more about the technique and its most popular applications!

1. Overview Of Blow Molding

Blow molding is a common method used to manufacture plastic products. In this process, a plastic tube is heated to its melting point and then placed in a mold cavity to create plastic objects. The molten plastic is inflated with compressed air to take on the shape of a predetermined hollow mold. And air pressure and the amount of plastic used determine the final product's thickness.

The method has a long history. In the 1800s, blow molding - a technique derived from glass blowing - was employed to inflate celluloid polymers. Early techniques, though, were unsuitable for large-scale manufacturing. Commercial blow-molded bottle manufacturing equipment was created in the 1930s, allowing for large production. However, the materials took too long to produce in large quantities, and they were too brittle. The advent of low and high-density polyethylene led to the widespread use of blow molding, which transformed sectors such as the automobile and soft drink bottling industries.

Blow molding offers 2 main types: injection and extrusion. Each has its own advantages, but they both support elaborate designs, quick production rates, and affordable tooling costs.

Recommended materials for this technique are:

- Low and High-Density Polyethylene

- PVC

- ABS

- PET

- Nylon

- TPE

- Polypropylene

- Co-polyester

- EVA

- Polystyrene

- COP and COC

2. Products That Created From Blow Molding

There are various products in different industries created from blow molding, including:

There are various products in different industries created from blow molding, including:

- Automotive industry: Blow molding is a simple and cost-effective method for mass production. It is used in many components specialized in containing fluids, such as fuel tanks, windshield washer fluid bottles, and overflow containers for cooling systems.

- Households: Various bottles for detergent, liquid soap, and laundry are made by blow molding. The most popular materials include PP, PC, PE and HDPE.

- Medical/ Pharmaceutical/ Cosmetics: You can see how many hollow containers are used if you've visited a family doctor, dentist, or health center, including water bottles, spray bottles, and storage containers lining the cabinets. Similarly, you can find many plastic blow-molded bottles and jars for cosmetics ranging in different sizes. That's all products of blow molding.

- Toys: Many manufacturers use this technique to produce toys since it makes complex shapes and sizes possible while other manufacturing methods can't do.

- Lawn, garden outdoor products: Blow molding offers a sturdy, long-lasting, weather-resistant structure for products. That's why it's used for manufacturing outdoor furniture, construction barrels, gardening supplies such as watering pots, and outdoor blow mold décor items.

- Sport goods: Various sport equipment made by blow molding, including plastic ball, plastic bat and hollow piece of equipment.

- Electronics components: The highlighted applications are the cases for gadgets.

- Marine: Products that are submerged in water must be buoyant, and hollow products are easily created using blow molding. Blow molding is frequently used to create buoys, reservoirs, and other items.

- Packaging industry: Blow molding simplifies the manufacture of complex shapes and creates customized packaging to keep products safe.

- Industrial bulk containers: Bigger fluid containers for the transportation and storage of liquids, such as water or oil are constructed using blow molding.

3. Conclusion

Blow molding products present in many industries such as automotive, electronic, toy and packaging. Since the method offers a high level of customization, it's used for the production of intricate shapes and designs.

The technique is fast and effective, allowing the manufacturing of huge quantities of products in a short amount of time, and it is cost-effective, needing little labor and material costs.

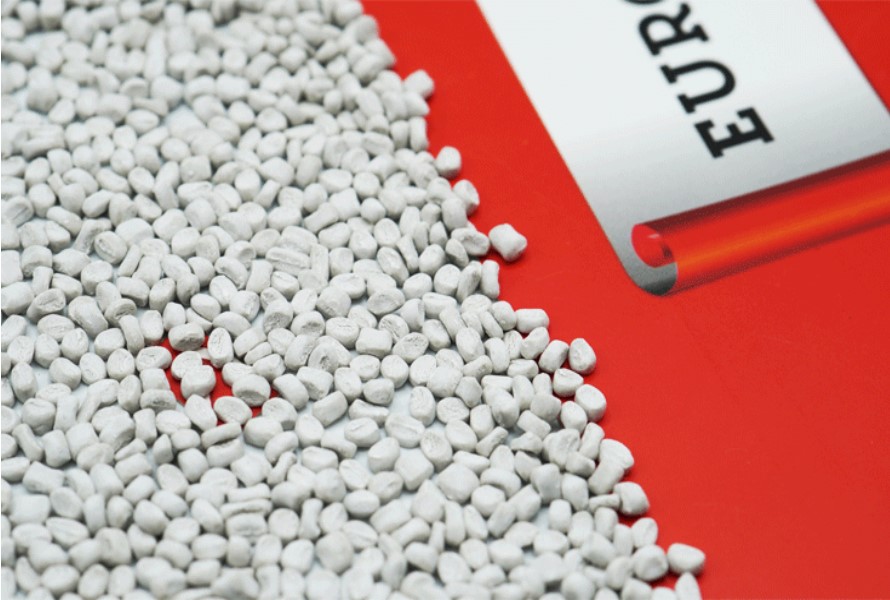

4. About EuroPlas

As a leading expert, EuroPlas provides innovative raw material solutions for plastic to maximize production efficiency and businesses' competitiveness in the market. With thousands of manufacturers in almost 100 countries using EuroPlas products, the company provides a unique advantage in natural resources, customized solutions, and affordable materials.

As a leading expert, EuroPlas provides innovative raw material solutions for plastic to maximize production efficiency and businesses' competitiveness in the market. With thousands of manufacturers in almost 100 countries using EuroPlas products, the company provides a unique advantage in natural resources, customized solutions, and affordable materials.

Our products include:

- Engineering plastic compound

- Color masterbatch

- Filler masterbatch

- Plastic additives

- Bioplastic compound

- Bio filler

Contact EuroPlas for more consultation!