When designing a polymer component that will be exposed to severe chemicals for an extended time, engineers must prioritize the chemical resistance of plastics as much as feasible. Read our article to discover the factors influencing chemical resistance, the most common chemical resistant plastics, and their applications.

Related:

- Chemicals used in the manufacture of plastics

- Why Does Plastic Turn Yellow Over Time? Preventing Plastic Discoloration

I. Is plastic chemical resistant?

Some types of plastics do achieve excellent chemical resistance. This feature depends on the plastic's chemical formula itself.

Chemically inert plastics are utilized in various areas, such as machinery, chemical containers, diaphragms, semiconductors, aerospace, and electronics. To attain high operational safety and reliability, engineers must design their facilities such that the components can withstand interaction with chemical substances.

II. The chemical resistance of plastics

Chemical resistance is a word used to characterize a material's resistance to the effects of chemicals. Inadequate chemical resistance manifests itself as discoloration, blistering, or softening, resulting in a loss of mechanical characteristics and overall serviceability.

1. Factors influencing the chemical resistance of plastics

The following information embraces those factors that influence the chemical resistance of plastics, which are temperature, the concentration of chemicals, duration, mechanical loads, weather impacts, environmental stress cracking, and electrical conductivity.

Temperature: The chemical resistance of plastics usually decreases with high temperatures. This behavior can thus be used to forecast a plastic's long-term behavior. Suppose storage test results at temperatures higher than the needed temperature are available. In that case, it is feasible to predict how the plastic will react in the case of long-term exposure to a chemical media at the desired low temperature.

The concentration of chemicals: Some chemicals are kept in solution with water rather than utilized in their pure state. It is critical to select a chemical resistant plastic that can withstand a chemical at whatever concentration level you demand. The higher a chemical's concentration, the more probable it is to destroy plastic materials.

- Duration: Before selecting a plastic material, consider how long a part will be exposed to chemicals. Even chemical-resistant polymers can begin to degrade after extended contact.

- Weather impacts: Specific polymers that are exposed to sunshine and weather for extended periods outside are physiologically and chemically changed. The end result may be discoloration, brittleness, and mechanical property loss. This also has an impact on resistance to chemical media.

- Environmental stress cracking: Environmental stress cracking or ESC occurs when plastic is subjected to internal and external forces. Internal stresses are imposed on a plastic component during manufacture and processing. External pressures are imposed on the part due to mechanical load. As a result, when a chemical damages the structure of plastic, the plastic material can have thin and spiderweb-like cracking.

- Electrical conductivity: In many applications, plastics must have strong electrical conductivity and excellent chemical resistance. These properties are critical for storing chemicals with a low flash point, such as heating oils, gasoline, or lubricating oils.

2. Chemical resistance chart for plastics

III. Chemical resistant plastics

1. 5 common chemical resistant plastics

1.1. PTFE (Polytetrafluoroethylene)

PTFE, sometimes known as Teflon, is a tough and durable synthetic fluoropolymer composed of carbon and fluorine atoms. When forming complex shapes, it will flex rather than shatter.

In addition to its flexibility, PTFE has been considered one of the best chemical resistant plastics with excellent weathering resilience. Only organic halogenated substances, such as chlorine trifluoride (ClF3), oxygen difluoride (OF2), molten alkali metals, and gaseous fluorine, can attack it at high temperatures.

Moreover, PTFE has excellent electrical insulating qualities, a very low dielectric constant, a low coefficient of friction, and high heat resistance. It also has good mechanical features but is weaker than standard engineering plastics. However, the inclusion of fillers has overcome those disadvantages.

As a result, PTFE is an ideal choice for components that must be resistant to chemicals while remaining bendable during and after manufacture. PTFE's typical applications are:

- Cookware: Used to coat non-stick pots and pans.

- Medical: Used to make artificial body parts such as cardiovascular grafts, heart patches, or ligament replacement.

- Machinery: Used to make machine parts, such as plugs, gears, pump parts, pipe linings, joints, slide plates, non-stick surfaces, O-rings, and saw blades.

- Electronics: Used to make insulators in cables and flexible printed circuit boards.

- Chemical: Used as a liner in hose assemblies, expansion joints, and reaction vessels, mainly where acids, alkalis, or other chemicals are present.

1.2. PEEK (Polyetheretherketone)

PEEK, or polyetheretherketone is a plastic resistant to strong chemicals, saltwater, and steam. PEEK retains firmness even at high temperatures. PEEK produces less smoke and toxic fumes when exposed to flame, making it more applied in high-temperature industries.

PEEK has great mechanical properties and dimensional stability. It is effortless to produce and may be formed into complicated forms. PEEK is available in sheet, rod, and tube form, with color and grade variations, and has several manufacturing uses:

- Food and beverage: Used in oil, food storage, and food processing.

- Aerospace: Used to make engine and interior parts to minimize gas and smoke emissions.

- Medical: Used to make medical instruments such as dental syringes, sterile boxes, and implants.

- Electronics: Used as a semiconductor in semiconductor machinery and electrical connectors.

1.3. PVC (Polyvinyl Chloride)

PVC (Polyvinyl Chloride) is a strong and tough thermoplastic. It is simple to fabricate and easily binds with solvents and adhesives. PVC is also great for combining components, making it ideal for constructing fittings and valves.

PVC comes in various colors and grades, so designers will have many options if they choose this chemical resistant material. Because PVC is so affordable and widely used in pipe applications with harsh environmental conditions, engineers have been able to improve PVC's chemical resistance properties over time.

PVC is an essential material in many industries:

- Construction: Being used in making pipes and fittings, cable and services ducting, internal and external cladding, flooring, or wallcoverings.

- Healthcare: Used in making artificial skin for burns treatment, blood and plasma transfusion sets, blood bags, surgical and examination gloves, etc.

- Electronics: Being used in insulation on electrical wires.

- Houseware: Used to manufacture aprons, shower curtains, raincoats, garden hoses, jackets, and sports bags.

- Automotive: Used in making instrument panels and associated moldings, interior door panels and pockets, seat coverings, mud flaps, exterior side molding, and protective strips.

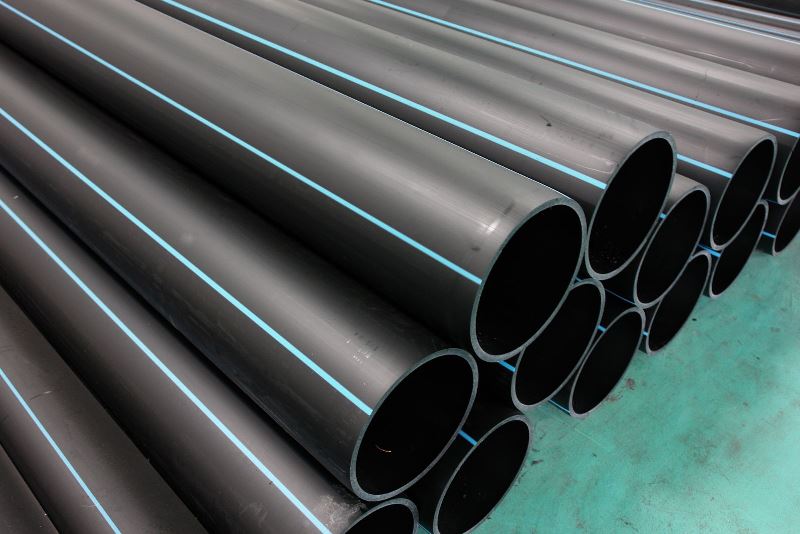

1.4. HDPE (High Density Polyethylene)

HDPE, which is the abbreviation of High Density Polyethylene, is a thermoplastic with excellent chemical and corrosion resistance. Its low moisture absorption characteristics contribute to its chemical resistance, boosting a product's chemical resistance absorption.

Other notable qualities include a high melting point, flexibility, and low price. It has a linear structure with minimal branching, resulting in a more robust molecular structure and higher tensile strength.

It is one of the most high-grade chemical resistant plastics that may be used in various fields:

- Construction: Used in building public infrastructure and spaces and military constructions.

- Fibers & textiles: Used to make fabrics, ropes, fishing, and sports nets.

- Pipes: Used to make water pipe flanges, light-duty tanks, cable protection, and sea downspout.

- Food packaging: Used to manufacture jerrycans, liquid bottles, bulk containers, etc.

1.5. PP (Polypropylene)

PP (polypropylene) is a chemical resistant plastic with a low cost and strong stress-crack resistance. PP is also very formable, making it simple to weld while staying rigid and durable. It is lowly resistant to compounds such as diluted acids, alcohol, and bases but resistant to ketones, esters, hydrocarbons, and aldehydes.

One disadvantage of PP is its relatively low melting point of 120°C, much lower than the melting points of the other materials on this list. However, it still has a wide range of applications:

- Consumer goods: Used to make toys, furniture, food trays, or body jackets.

- Outdoor equipment: Used for terraces, patios, playground fixtures, roofing, and hurricane panels.

- Automotive: Used to make door trims, instrumental panels, fender lines, battery cases, trays, boxes, etc.

- Medical: Used to manufacture syringes, specimen bottles, diagnostic devices, pill containers, etc.

- Fibers & fabrics: Used to make staple fibers or stapes.

2. Chemically resistant plastics applications

The applications of chemically resistant plastics are really diverse, depending on not only their chemical resistance but also their mechanical properties, heat resistance and flexibility. But mostly, the chemically resistant plastics applications are:

- Storage tanks for chemicals

- Pipes and tubes

- Mechanical, electronics, and food machinery parts

- Laboratory equipment

- Artificial body parts

- Medical equipment

When designing, engineering, and manufacturing components for usage in severe environments, it's critical to choose the most chemically resistant plastic available. Some polymers are more resistant to high temperatures and UV radiation than others, while others resist moisture absorption and breaking better.

The engineer must choose carefully to guarantee that the material meets the application criteria. Testing the product is a good way to ensure compatibility. Performing several types of stress testing will supply the engineer with sufficient knowledge about the product's capabilities.

The chemical resistance of plastics should be prioritized when designing a storage or machine that exposes directly to chemicals. The most common chemical resistant plastics include PTFE, PEEL, PVC, HDPE, and PP. Those plastics have many vital applications in all industries. Hope the information in this article helps you choose the right plastics for your project.