The short answer is yes. It is, and it will remain a noteworthy term in the market of plastic application for decades later.

According to the newest report from Business Wire, the masterbatch market reached $16 billion dollar in the year 2016, almost double the size of the silicone market (GVR, 2017). Plastic packaging industry’s producers are seeking this additive material in mass to reduce the cost of coloring raw polymer.

1. What is masterbatch?

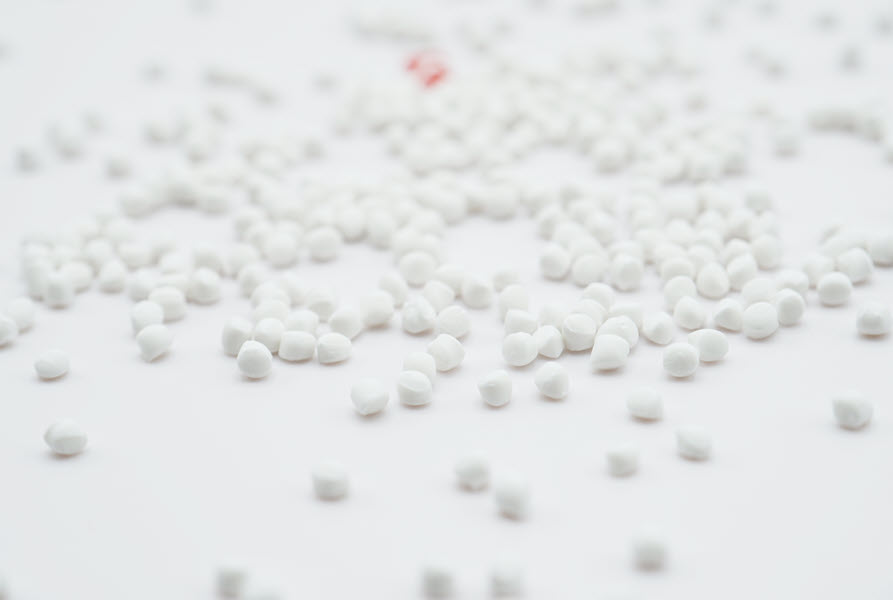

Masterbatch is, in short, a solution to “dye” plastic goods. It combines a mixture of additives and pigment into a carrier resin. Usually, it is often presented in four group: white, black, colored, and additive masterbatch. According to the BW report, nearly 30% of the global masterbatch revenue in 2016 accounted for white masterbatch.

2. Why are they becoming so popular?

What drives the demand for masterbatch comes from the packaging industry, construction sector, and automotive market. For decades, the plastic packaging industry plays as the source of demand for white masterbatch, since it is often chosen as the base color to produce milk bottles, plastic bags, food packaging, and pharmaceutical packaging. In 2017, Clariant, the world leader in plastic application announced the launch of a new EP white masterbatch, specially targeted for the pharmaceutical packaging market.

However, what is changing now is a strong drive in the automotive market, especially from South East Asia and other emerging markets. This growth is due to the mass optimization of vehicle parts. Producers have been replacing metal pieces with plastic-made items in order to reduce production costs and enhance the long-lasting use of the components. Plastic parts are also easier to mold and exchanged when needed. In the end, it leads to cheaper costs for consumers and serves the purpose of increasing the consumer base in developing countries.

3. Masterbatch trends in the coming years

Industry specialists have reported on the increasing trend in researching Nano-based Masterbatch. Though the topic may sound far-reaching and unfamiliar, the use of nanotechnology in producing masterbatches is not new.

Pigments used in manufacturing masterbatch are not often considered to be nano-materials, but many meet the condition of nano-material classification. Using nanotechnology to control the ratio of color mix and particle size of the plastic particles has been under serious research by the British Plastic Federation. Together with the rise in demand of producers for new material is the consumer’s increasing awareness of plastic recycling. This can result in large investments flowing into the recycling sector and further changes in national-level production regulation.

Recently, the British government announced its plan to shift all the costs of waste disposal to plastic packaging manufacturers, accounting for them as the main culprit for environmental suffering. Nevertheless, it leads to the question of whether plastic producers would increase their prices as the result and eventually tip the damage toward the customers themselves.

4. About European Plastic Company

Founded in 2007, European Plastic Company (EuP) is the top producer and exporter of CaCO3 filler and masterbatch in Vietnam. We are authorized by the Vietnam Government to exploit the rich calcium limestone resource with over 100 years in formation. EuP has been a reputable partner of plastic producers from 70 countries across the world. Visit

our website for more details or contact us via info@europlas.com.vn