The look of carbon fiber

Recently, as the market increasingly emphasizes product performance, questions such as what is carbon fiber, how to make carbon fiber, and why carbon fiber is so expensive are always asked by many investors. The reason for this care is because among a series of materials containing many economic benefits, carbon fiber is still one of the notable names. Carbon fiber offers a number of unique benefits that other materials cannot provide. Currently, fields such as aerospace, automobiles and sports equipment tend to favor carbon fiber thanks to its optimized performance and high durability. This is a material that contains all the advantages such as lightness, durability, anti-corrosion, high antibacterial, diverse and flexible applications that make other materials unmatched. Despite its excellent characteristics, carbon fiber is often considered to be quite expensive as a material. Now let's find out whether the investment cost for carbon fiber is really worth it compared to the economic potential it brings!

1. What is carbon fiber?

Carbon fiber on car

Carbon fiber, also known as graphite fiber, belongs to the polymer group. This is an ideal material that is very commonly used in production, bringing great benefits to both manufacturers and consumers. Carbon fiber is a material consisting of crystalline carbon fibers thinner than a human hair twisted together into long strands. They will then be woven together into fabric or some specialized material. Most carbon fibers are produced using polyacrylonitrile (PAN) as a precursor. It is 5 times stronger than steel and twice as strong, much lighter than steel. Due to its excellent properties and texture, engineers and designers tend to choose carbon fiber in product application and manufacturing. The basic benefits that carbon fiber brings include hardness, high durability, good elasticity, high temperature resistance, little deformation due to external impacts (weather, high temperature...) and Extremely good chemical resistance. Besides, the manufacturing process is relatively complex and requires a highly skilled production team.

2. How to make carbon fiber?

2.1 Overview

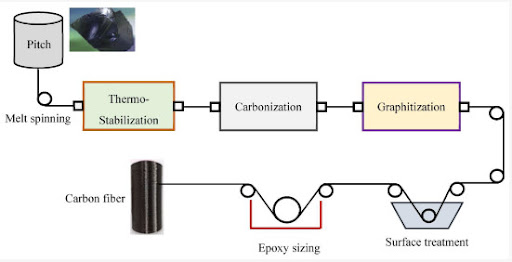

The process of making carbon fiber

The production of carbon fiber starts from raw materials that can be called precursors. As mentioned above, the majority and specifically about 90% of carbon fibers are derived from a precursor called polyacrylonitrile (PAN). Additionally, some substances that can create carbon fibers are rayon or petroleum resin. Then, these materials will go through a rather complicated process to create finished carbon fiber. Depending on the manufacturer's commercial purposes, changing the ratio of the above substances can directly affect the quality of the fiber. See more about the high-quality carbon fiber production process here!

2.2 Atomic stabilization of the precursor

Stabilizing of the precursor

Before starting the carbonization process, the precursors need to be processed to convert their atomic bonds to suit the production needs. The precursors will undergo a heating process in air at a temperature of about 200 - 300 degrees Celsius for about 30 to 120 minutes (depending on the material). Once heated, the fibers receive oxygen molecules from the air and undergo a process of rearranging their atomic bonding pattern.

This stabilization process is also quite complicated and needs to be monitored and controlled from start to finish to avoid overheating the fiber. Equipment and processing techniques are also very diverse such as heat chambers, hot rollers, suspended chambers, or chambers mixed with hot air mixed with some other gases to make the heating process more effective.

2.3 Carbonizing

Carbonization process

After going through the stabilization process, these materials will be spun into long fibers and then heated at very high temperatures of about 1000 - 3000 degrees Celsius. At this temperature, the atoms in the fibers vibrate with very high intensity. Most non-carbon atoms including water vapor, ammonia, carbon monoxide, carbon dioxide, hydrogen, nitrogen and others will be expelled. This process helps remove non-carbon elements from them to form pure carbon atoms in the crystal structure. Besides, this process is also completely separate from oxygen as the places where fibers enter and exit the furnace are all tightly sealed. An oxygen-free environment will prevent the raw fibers from burning or shrinking. At the end of the carbonization process, we obtain material fibers consisting of long strands of carbon atoms tightly twisted together. Finally, the carbon fibers will be processed and rolled into rolls for convenient storage and transportation.

2.4 Treating the surface

Epoxy on black carbon

Although it has undergone the carbonization process, the surface of carbon fiber is still not considered to be perfectly bonded. To handle this condition as well as enhance bonding, carbon fibers will undergo another process called oxidation. Specifically, carbon fibers will have oxygen atoms added to the surface, providing better chemical and mechanical properties. Carbon fibers can be processed by electrolytic coating, immersion in media such as air, ozone, carbon dioxide, sodium hypochlorite or nitric acid. The surface treatment process will also be extremely strictly controlled to avoid small defects such as pits or scratches that can greatly affect the quality of the fiber.

2.5 Sizing

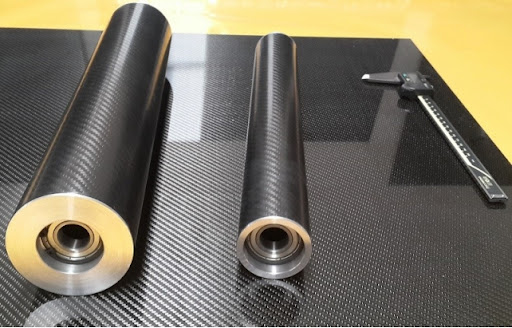

Carbon rolls

After surface treatment, the fibers are coated on the outside with substances such as poxy, polyester, nylon, urethane and some other types depending on business needs and strategies. This protective layer helps protect it from damage or scratches during the weaving or winding process. At this step, the carbon fibers will be shaped into large and small rolls depending on packaging or transportation needs.

3. Why is carbon fiber so expensive?

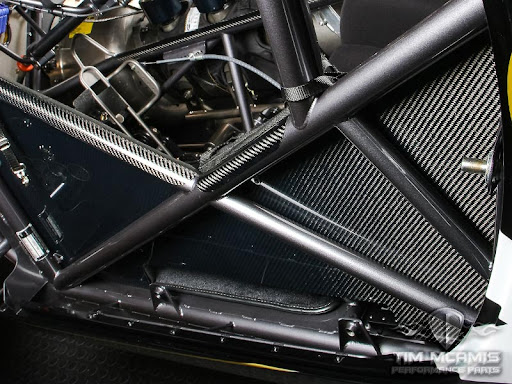

Carbon fiber application in moto

3.1 Production process

The carbon fiber production process is considered quite complicated because it takes a long time and requires professional production equipment. Besides, the production process requires a team of skilled engineers to operate the equipment and closely monitor to create the most perfect carbon fiber. This makes the cost of the material higher than other materials.

3.2 Performance and return on investment (ROI)

Replacing carbon fiber with other materials requires higher investment costs. However, carbon fiber offers many times more performance than its initial cost. For example, in the aviation industry, replacing materials with carbon fiber helps aircraft significantly reduce weight, thereby expanding flight range and reducing wear and energy consumption. According to the investor's long-term vision, the value of carbon fiber is completely worth the initial production cost.

4. Conclusion

In short, carbon fiber can be considered one of the top quality manufacturing materials. Products made from carbon fiber have advantages in durability, lightness, rigidity and are less susceptible to deformation due to external impacts. Although the price is higher than other materials, in terms of product performance, carbon fiber is not only completely worth the initial investment price but also minimizes the risk of damage and complicated maintenance. You can easily find useful articles about material selection for your upcoming project, check out more at EuroPlas!