In the agricultural and food packaging industry, dew is not an unfamiliar concept. Condensation of water vapor onto agricultural films or food packaging hinders crop yield and product attractiveness. In this article, we will learn what fog is and how to fix it in plastic products.

Related:

- What are plastic additives? 8 most common plastic additives in plastic industry

- Slip additives and antiblock additives for extrusion industry

- Antistatic Agents Overview

- UV stabilizers for plastics - everything you need to know

- Automotive UV stabilizers - All you should know

1. What is dew condensation and the effect of dew on the surface of plastic products

Dewdropping is the phenomenon of water droplets clinging to the surface of a solid object. Some of the effects of dew may include:

- Dew will prevent the light from passing through the greenhouse, reducing photosynthesis, reducing crop yield, and being more susceptible to pests and diseases.

- Dew condensation makes the product inside the package not visible, making it difficult to see the product inside; reduces the aesthetics and attractiveness of the product to consumers.

Therefore, to increase the amount of light entering the greenhouse or to easily observe the product inside the package, we should add anti-fog masterbatch to the plastic.

2. Benefits of anti fog masterbatch

Difference between not using and using anti-fog additive for film

The photo above is an experiment with 2 plastic film products. One product does not use anti-fog additive, the other is added anti-fog additive, code EM AF 209, 1-7% concentration of EuroPlas. Easily recognizable, products containing anti-fog additives have much less water vapor on the surface. In the next chapter, we will dive into the process of fogging and how to improve this problem.

3. An overview of fogging and how to remove it

3.1. Fogging process

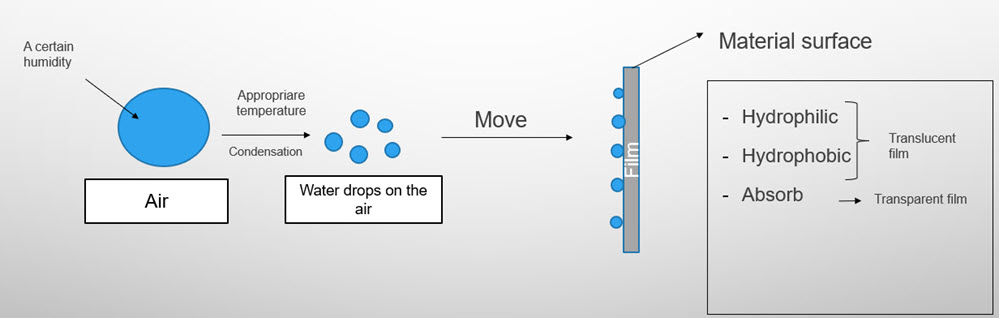

What is dew? They are water droplets condensing in the air, dependent on humidity and temperature. Dew condensation occurs when dew particles adhere to the surface of a material.

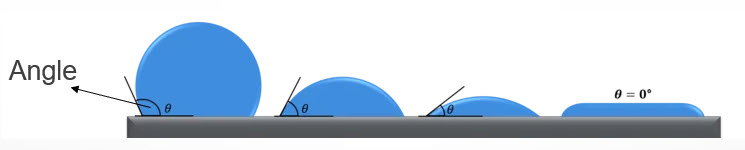

The shape of the dew on the surface of the material

The shape of the dew on the surface of the material is estimated as follows:

- Surface hydrophobic material: angle ≥ 90°

- Surface hydrophilic material: angle 0 <θ< 90°

- The surface of the material is completely wetted: angle = 0

- Angle θ : (contact angle) angle made by the surface of the material with the drop of water

3.2. How to avoid fogging on plastic surface

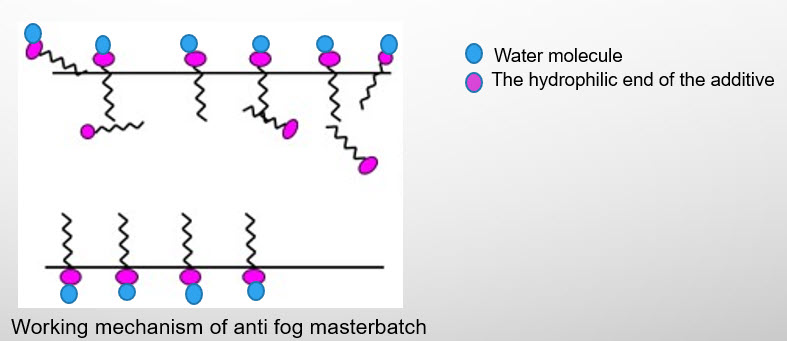

The way to improve the problem of turbidity caused by fog is to change the film, and the plastic surface from hydrophobic to hydrophilic and completely absorbent. As a result, the water will turn thin on the surface of the product.

To do so, we use anti-fog additives. The additive used is a surfactant with one hydrophilic and one hydrophobic end. Some commonly used compounds are GMS, GMO, and Polyglycerol esters (PGE). When using anti-fog masterbatch, there are a few things to keep in mind:

- Suitable for conditions of use

- An appropriate amount of use (ensure travel speed)

- Long operating time

- Can be combined with other additives (such as anti-UV, anti-block, and slip additives)

- Does not affect the mechanical properties and color of the product

4. EuroPlas anti-fog masterbatch

With more than 15 years of experience in the production of plastic materials, EuroPlas is always proud to provide quality products that meet the needs of customers around the world. Our anti-fog additive masterbatch products are very popular thanks to the following features:

- Prevent water condensation on the plastic surface and ensure the transparency of the plastic film

- Suitable for using conditions

- An appropriate amount of use (ensure travel speed)

- Long operating time

- Can be combined with other additives (such as anti-UV additives, anti-block, slip)

- Does not affect the mechanical properties and color of the product

For more information and samples, please contact our consulting team today.