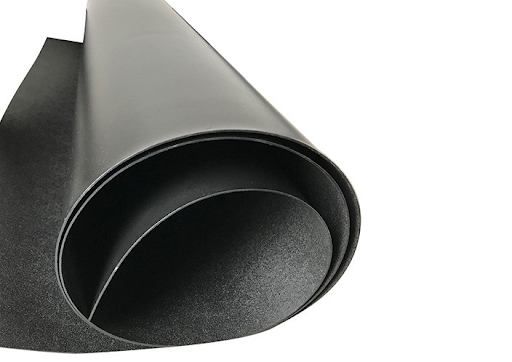

Thermoplastic elastomer is a highly appreciated plastic lines thanks to its versatility and impressive performance

Thermoplastic elastomer (TPE) is a strange concept in the plastic materials industry. Thermoplastic elastomer is one of the highly appreciated plastic lines thanks to its versatility and impressive performance. In fact, thermoplastic elastomers are divided into many subgroups with different outstanding properties. Each line of Thermoplastic elastomer will possess some of its strong advantages. A better understanding of thermoplastic elastomer groups helps us take full advantage of their outstanding properties. The following article will analyze some popular TPE lines, their properties and applications!

Read more: All about TPE plastic: Definition, properties & applications

1. Seven types of Thermoplastic Elastomer

Thermoplastic elastomers are divided into many subgroups with different outstanding properties

- Styrenic Block Copolymers (TPS)

TPS is one of the materials belonging to the group of thermoplastic elastomers that is quite popular today. TPS products include at least a three-block copolymer of styrene and a specific diene in which the last two segments are polystyrene and the inner soft segment is polydiene or hydrogenated polydiene.

- Thermoplastic Polyurethanes (TPU)

TPU plastic's full name is thermoplastic polyurethane plastic. This is a plastic line belonging to the thermoplastic group that is processed by the melting process. Among them, TPU plastic stands out with the properties of both rubber and plastic such as flexibility, toughness, and good tensile strength. Typical application fields of TPU include automotive technology, cables, and some sports equipment.

TPO is also one of the popular plastic lines belonging to the thermoplastic group

TPO is also one of the popular plastic lines belonging to the thermoplastic group. TPO is a mixture of polypropylene (PP), polyethylene (PE), block copolymer polypropylene (BCPP), rubber and reinforcing fillers. Because of its thermoplastic properties, this material can be easily heat treated. They are often processed by methods such as blow molding, injection molding, and extrusion etc.

Read more: TPO Plastic: Everything you need to know

- Thermoplastic Vulcanizates (TPV)

This material has outstanding heat resistance, so it is often used in the field of automotive technology, pipes and some applications that require relatively good heat resistance. In addition, TPV plastic is also quite hard with hardness values ranging from about 45A to 45D. They are good candidates for technical applications that require rigidity and durability.

- Thermoplastic Copolyesters (TPC)

TPC plastic is also considered one of the popular plastic lines of the thermoplastic group. This material line possesses some quite outstanding features so it is widely used in a variety of technical applications. Typical properties of TPC include high temperature performance, good elasticity, anti-wear ability and good chemical resistance. TPC plastic provides consumers with a product with a long lifespan thanks to its ability to stretch and restore its original shape. This is one of the thermoplastic lines that possesses extremely outstanding properties.

- Thermoplastic Polyamides (TPA/TPE-A)

Thermoplastic polyamide has the abbreviation TPE-A or TPA. They are one of the thermoplastic lines that are considered to exhibit excellent mechanical, thermal and chemical properties. TPA plastics belong to the thermoplastic group, so they can be completely melted and reshaped while still retaining their inherent properties. They are usually processed by methods such as injection molding, extrusion, etc. In terms of properties, TPA plastic stands out with good chemical resistance, significant heat resistance and outstanding mechanical properties. According to current assessments, TPA plastic is one of the elite thermoplastic lines because of its high durability and outstanding performance.

In addition to the above plastic lines, TPE thermoplastics are also classified into many different subgroups. Some of them include copolyester (COPE), copolyamide elastomer (PEBA) and silicone-based TPE. Each of the plastic lines mentioned above will have their own unique properties. This can be understood as each line will also have its own strengths in each application.

2. Common Properties of Thermoplastic Elastomers

Thermoplastic TPE is known as one of the material lines with high flexibility in both production and application processes. The following are some outstanding properties of thermoplastic elastomers (TPE):

-are-famous-for-their-ability-to-be-recycled-and-reshaped-after-being-melted.png)

Thermoplastic elastomers (TPE) are famous for their ability to be recycled and reshaped after being melted

- Durability: Thermoplastic elastomers (TPE) are considered one of the material lines that provide optimal durability for many applications. They possess outstanding mechanical properties such as good elasticity, high flexibility, good fatigue strength and resistance to corrosion caused by external influences (harsh weather, corrosive acids, etc.). The above properties help thermoplastic elastomers (TPE) have impressive performance over many years.

- Energy saving: the production process of thermoplastic elastomers (TPE) saves a lot of energy compared to thermosetting plastics. In application, thermoplastics are light in weight, so they help machines operate more smoothly and consume less raw materials.

- Environmentally friendly: thermoplastic elastomers (TPE) are famous for their ability to be recycled and reshaped after being melted. This helps limit most waste into the natural environment and reduce the greenhouse effect.

- Flexible manufacturing: the production process of thermoplastic elastomers (TPE) is quite diverse. Some common hot melt manufacturing processes include injection molding, extrusion molding, blow molding, etc. They are extremely flexible thanks to their adaptability to many forms of production.

- Easy to color: thermoplastic elastomers (TPE) can be colored in a wide variety of colors. They can be easily dyed and mixed into many colors according to each design requirement.

3. Common Applications of Thermoplastic Elastomers

TPE are designed to be flexible and compatible with many designs thanks to flexible molding capabilities

Thermoplastic elastomers (TPE) are widely used in the field of automotive technology. They are ideal for the production of covers, bodies and a number of other parts thanks to their flexibility, high abrasion resistance and strong chemical capabilities.

Some medical devices are manufactured from thermoplastic elastomers (TPE), such as syringe stoppers, medical masks, breathing tubes and a number of other sealing parts.

The electronic components manufacturing industry applies thermoplastic elastomers (TPE) to a number of products such as phone cases, cables, sockets and plugs. They are designed to be flexible and compatible with many designs thanks to flexible molding capabilities.

Some outdoor applications that thermoplastic elastomers (TPE) have contributed to include porch covers, furniture covers, and some patio covers. It's all thanks to their high abrasion resistance that helps them work well even when the weather changes erratically.

Some product packaging covers are also applied with thermoplastic elastomers (TPE) such as electronic equipment packaging, machinery component packaging, phone covers and some other household appliance covers.

Common applications of thermoplastic elastomers (TPE) in sports production include handle covers, shoes, and protective covers. Sports products made with thermoplastic elastomers (TPE) often have good flexibility and corrosion resistance.

4. Conclusion

In conclusion, thermoplastic elastomers (TPE) are divided into many diverse subgroups. Each group of thermoplastic elastomers (TPE) will possess many similar advantages and a few of their own unique advantages. In general, thermoplastic elastomers (TPE) are highly appreciated in the manufacturing industry thanks to a number of outstanding features such as high durability, flexibility, resistance to corrosive chemicals and suitability for a variety of production processes. export. Thermoplastic elastomers (TPE) are widely used in many diverse fields such as automotive technology, medicine, electronics, component packaging, etc.

5. About EuroPlas

With many years of experience in the material manufacturing industry, EuroPlas is proud to be one of the reputable and reliable sources of plastic materials. You can easily find many lines of high quality plastic products at EuroPlas. Update loads of useful information on the EuroPlas blog today!