A comparison of HIPS vs. HDPE

When it comes to selecting the right material for various applications, understanding the differences of High Impact Polystyrene (HIPS) vs High-Density Polyethylene (HDPE) is crucial. Both HIPS and HDPE are widely used in industries such as packaging, construction, automotive, and more. In this article, we will thoroughly compare the properties and applications of HIPS vs HDPE to help you make informed decisions.

1. What is HIPS?

HIPS stands for High Impact Polystyrene. It is a synthetic polymer that belongs to the polystyrene family, and is derived from styrene monomers through a process known as polymerization. HIPS is known for its combination of toughness, impact resistance, and ease of processing. It

HIPS is a versatile material with a wide range of applications. Its properties make it suitable for applications that require impact resistance, dimensional stability, and a smooth, glossy finish. Therefore, It is commonly used in industries such as packaging, consumer goods, electronics, automotive, and construction.

Read more: Advantages and disadvantages of HIPS plastic - Best in class HIPS compounds

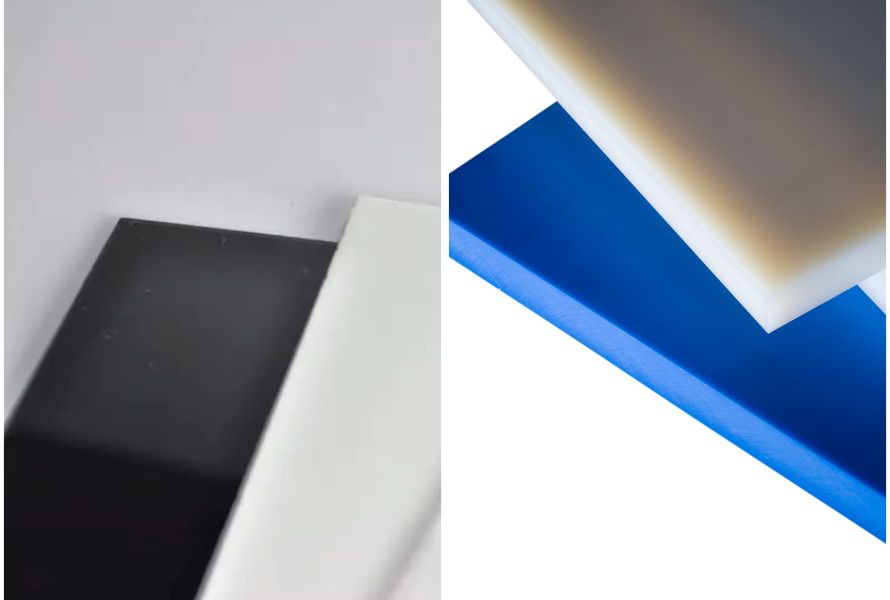

Synthetic polymer HIPS is a member of the polystyrene family

2. What is HDPE?

HDPE stands for High-Density Polyethylene. It is a thermoplastic polymer that is derived from the monomer ethylene through a process called polymerization. HDPE is known for its excellent strength, durability, and resistance to different environmental factors.

In the construction industry, HDPE is used for applications such as pipes, geomembranes, and insulation. In agriculture, it is used for irrigation systems, greenhouse films, and agricultural tanks. In healthcare, HDPE finds applications in medical bottles, containers, and laboratory equipment. It is also widely used in packaging for products such as bottles, containers, and caps.

Read more: HDPE (High density polyethylene) - What is it? Properties & common uses

A procedure known as polymerization is used to create HDPE, a thermoplastic polymer, from the monomer ethylene

3. A comparison of HIPS vs HPDE

Here's a short table comparing HIPS vs HDPE based on some key properties:

| Properties |

HIPS |

HDPE |

| Density |

Medium density (1.03-1.06 g/cm³) |

High density (0.941-0.965 g/cm³) |

| Strength |

Good impact resistance |

Excellent tensile strength, rigid |

| Temperature Resistance |

Limited resistance to high temperatures |

Good resistance to a wide temperature range |

| Chemical Resistance |

Moderate resistance to chemicals and solvents |

Excellent resistance to acids, alkalis, solvents |

| Moisture Resistance |

Moderate resistance to moisture |

Excellent resistance to moisture, humidity |

| Weatherability |

Moderate resistance to weathering |

Excellent resistance to UV radiation, weathering |

| Processing method |

Injection molding, extrusion, thermoforming |

Injection molding, blow molding, rotational molding |

| Applications |

Packaging, consumer goods, signage, automotive interior components |

Construction, agriculture, healthcare, packaging |

| Cost |

Generally more economical |

Varies depending on market conditions, volume, and grades |

| Environmental sustainability |

Recyclable and reusable |

Recyclable, exhibits good environmental sustainability |

3.1. HDPE vs HIPS: Density

HIPS is characterized by a medium density, typically ranging from 1.03 to 1.06 g/cm³. On the other hand, HDPE is classified as a high-density material, with a density typically ranging from 0.941 to 0.965 g/cm³. This indicates that HDPE is denser than HIPS.

3.2. HIPS vs HDPE: Strength

When it comes to strength, HIPS (High Impact Polystyrene) and HDPE (High-Density Polyethylene) exhibit different characteristics. HIPS is known for its good impact resistance, which means it can withstand sudden impacts without breaking or fracturing.

Meanwhile, HDPE boasts excellent tensile strength. It can withstand significant amounts of tensile stress without deforming or breaking.

HIPS offers good impact resistance but is outperformed by HDPE in terms of overall strength and rigidity

3.3. HIPS vs HDPE: Temperature Resistance

Regarding temperature resistance, there are notable differences between HIPS and HDPE.

HIPS has a limited resistance to high temperatures. It begins to soften and deform at relatively low temperatures, typically around 70-80°C (158-176°F). Therefore, it is not suitable for applications that involve exposure to elevated temperatures or thermal stress.

In contrast, HDPE exhibits good resistance to a wide range of temperatures. It can withstand both high and low temperatures without significant deformation or loss of properties. HDPE has a relatively high melting point, typically around 120-130°C (248-266°F), which allows it to maintain its structural integrity in demanding temperature conditions. It also has good resistance to cold temperatures, making it suitable for applications in freezing environments.

3.4. HDPE vs HIPS: Chemical Resistance

HDPE boasts excellent chemical resistance across a wide range of substances. It is highly resistant to acids, alkalis, solvents, and many other chemicals. Additionally, HDPE's resistance to chemical degradation contributes to its longevity and durability in harsh environments

HIPS offers moderate resistance to chemicals and solvents. While it can withstand exposure to certain common household and industrial chemicals, it may not be suitable for highly corrosive or aggressive substances..

3.5. HIPS vs HDPE: Moisture Resistance

HIPS has moderate moisture resistance, while HDPE excels in moisture resistance. HIPS can withstand brief exposure to moisture but may be affected by prolonged exposure or immersion. Whereas, HDPE is highly impermeable to water and maintains its structural integrity and dimensional stability even in wet environments.

HDPE provides more moisture resistance compared to HIPS

3.6. HDPE vs HIPS: Weatherability

HDPE has a high level of UV resistance, which means that it can withstand fading and degradation of color brought on by prolonged exposure to the sun. In a variety of weather conditions, such as intense heat, cold, and humidity, HDPE also keeps its mechanical qualities and structural integrity.

Conversely, HIPS provides a moderate level of weather resistance. Even though it can tolerate exposure to sunlight and mild weather, long-term exposure to UV rays and other harsh environmental factors may eventually cause color fading, surface degradation, and a reduction in mechanical properties.

3.7. HIPS vs HDPE: Processing method

HIPS can be processed using injection molding, extrusion, and thermoforming. Injection molding produces precise parts, while extrusion creates continuous profiles or sheets. Additionally, thermoforming shapes heated HIPS sheets using molds or vacuum forming.

Rotational molding, blow molding, and injection molding are methods for processing HDPE. Rotational molding forms large, seamless, and durable items by heating powdered HDPE in a rotating mold; injection molding creates precise shapes; and blow molding produces hollow products, such as bottles.

3.8. HIPS vs HDPE: Applications

HIPS is commonly used in packaging, consumer goods, and signage, including food containers, toys, and signage materials. Its impact resistance and rigidity protect products during transportation.

HDPE is widely used in construction for pipes, fittings, and geomembranes. It is also utilized in outdoor furniture, playground equipment, and storage containers. HDPE's moisture resistance and UV stability make it popular in water management and healthcare for medical devices and packaging.

3.9. HDPE vs HIPS: Cost

HDPE costs a little bit more. It's a high-density polymer made using more expensive raw materials and sophisticated manufacturing techniques. Applications needing particular qualities, such as chemical resistance, durability, and outdoor performance, are better served by HDPE.

On the other hand, HIPS is generally more affordable than HDPE. It is derived from cost-effective polystyrene and has a straightforward production process. HIPS is commonly used in packaging and consumer goods for its cost-effectiveness.

HIPS is more cost-effective, while HDPE has higher material costs due to its properties and production process

3.10. HIPS vs HDPE: Environmental

HIPS has some environmental concerns. It is typically derived from non-renewable fossil fuel sources such as petroleum, and its production process often involves high energy consumption and carbon dioxide emissions. Additionally, HIPS is not biodegradable in the environment, contributing to plastic waste issues.

On the other hand, HDPE exhibits better environmental sustainability. It can be recycled and has a high potential for reuse due to its molecular structure and properties. HDPE is commonly recycled into various products, including plastic bottles, pipes, and containers. It is also more resistant to chemical degradation and has a longer lifespan compared to HIPS.

4. Conclusion

While HIPS excels in impact resistance and rigidity for packaging and consumer goods, HDPE stands out for its strength, chemical resistance, and applicability in construction and outdoor settings. Considering the environmental aspect, HDPE's recyclability and potential use of renewable sources make it a more sustainable choice. By understanding these factors, you can make well-informed decisions when selecting the appropriate material for your specific projects.

If you're searching for standard or specially made HIPS compounds, EuroPlas will be a reliable source that can accommodate your requirements. We offer three HIPS compounds: HIPS filler masterbatch, HIPS flame-retardant compound and HIPS conductive compound. For more details, Contact us right now!