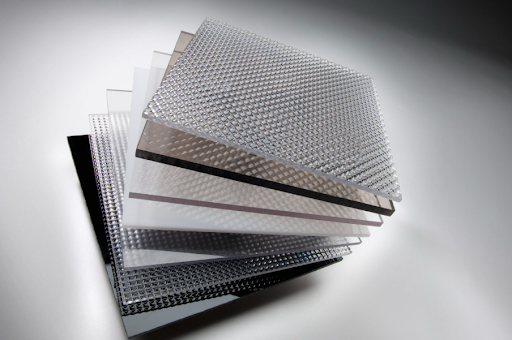

Polycarbonate plastic possesses countless outstanding internal advantages

Polycarbonate plastic is one of the popular keywords in the materials industry. They are one of the materials that contribute heavily in a variety of applications from mechanical engineering, medical equipment to daily life equipment. The reason for this wide application is because Polycarbonate plastic possesses countless outstanding internal advantages. The article below will clearly analyze the outstanding features of Polycarbonate plastic to help readers have the most detailed perspective on their features. In addition, let's take a look at the common applications of Polycarbonate plastic right below!

Polycarbonate plastic has a melting temperature between 288°C to 316°C

Polycarbonate plastic is abbreviated as PC plastic. Polycarbonate plastic belongs to the group of transparent, amorphous thermoplastics and has quite outstanding performance. PC plastic contains organic carbonate functional groups linked together in the form (–O–(C=O)–O–). Polycarbonate plastic has a melting temperature between 288°C to 316°C, which helps PC plastic possess stronger features and be used at a wider temperature range. They are amorphous so they can be easily melted and molded under high pressure to form shapes according to each design.

Polycarbonate plastic is widely used thanks to its impact resistance, high durability, dimensional stability, good electrical conductivity and light weight. In particular, thanks to its transparency and light weight, Polycarbonate plastic is considered a perfect alternative to glass.

Read more: What is polycarbonate plastic? Find out its amazing properties

2. Applications of Polycarbonate plastic

Polycarbonate plastic is one of the materials that possesses outstanding properties such as high durability, good heat resistance, good impact resistance, transparency and good reflection. They are always one of the ideal choices for many technical applications in diverse fields of life.

PC plastic always one of the ideal choices for many technical applications in diverse fields of life

Applications in automotive equipment that Polycarbonate plastic contributes to include headlight lenses, interior components and sunroofs, etc. They perform the role of these parts well thanks to their impact resistance and lightweight, easy-to-install properties.

Similar to the design in automotive equipment. Polycarbonate plastic also serves a number of roles in aircraft equipment due to its strength and lightness. Some applications include component covers, protective panels, and some parts in the fuselage to help reduce the weight of the machine.

One of the extremely popular applications of Polycarbonate plastic is equipment used in medical environments. Some applications include blood purifiers, surgical instruments, testing instruments, sampling vials, incubators, etc. It's all thanks to the transparency and good antibacterial properties of PC plastic

PC plastic is used in the designs of protective glasses, face shields, protective shields in construction and some other sports. This is thanks to their impact resistance and excellent transparency. In addition, thanks to their good heat resistance, they are also used to produce some fire protection layers.

It is very easy to come across optical lenses made from Polycarbonate plastic. Specifically, we can mention specialized optical glasses, camera lenses, etc

Some applications that Polycarbonate plastic contributes to in lighting equipment include fluorescent tube covers and LED light diffusers, etc. All thanks to the ability to transmit and diffuse light of them

PC plastic is used in the designs of protective glasses, face shields, protective shields

Some sports items such as protective shields, glasses, and helmets are also made from PC plastic. They give athletes a feeling of lightness and absolute safety.

Although not very popular, Polycarbonate plastic is also chosen by some brands to design food packaging and bottles. This partly shows the quality and reputation of the product.

Thanks to the insulating properties of PC plastics, they are also used in insulators, connectors and LED housings.

Thanks to its durability and impact resistance, PC plastic is commonly used in the production of laptop and tablet cases, smartphone cases and other electronic device components.

4. Conclusion

In conclusion, Polycarbonate plastic is always one of the materials worth investing in thanks to its excellent properties. Extremely sturdy features such as durability, unbreakability, and flexibility, but they are many times lighter than glass or metal. Thanks to that, the applications of PC plastic are also extremely wide and flexible, from technical and medical applications to applications in daily life. Polycarbonate plastic will always be on the list of ideal materials to help optimize costs for both investors and users.

5. About EuroPlas

At EuroPlas, we are proud to offer two product lines: PC Compound fireproof (PC-FR) and PC Compound fiberglass (PC-GF), which we dedicate to produce in accordance with international standards.

In particular, (PC-FR) is provided by EuroPlas according to 5 UL94 standard fire resistance levels: 5VA, 5VB, V0, V1, V2. These are safety-tested compounds for applications requiring enhanced user safety features. Besides, Europlas' PC-GF product ensures different proportions of glass fibers to give them the most specific mechanical properties.

Visit EuroPlas's blog if you are in need of a reliable companion in your upcoming projects. Our mission is to continuously update and share useful knowledge and documents with readers around the world. We always have the criterion of providing customers with the most optimal material solutions in both quality and price. In addition, EuroPlas also provides many typical materials such as biological fillers, bioplastics, colorants, additives and filler particles.

Read more: PC flame retardant compound

Read more: PC glass fiber compound