In the increasingly visual world of consumer goods, appearance is more than just a surface-level feature — it’s a decisive factor in purchase behavior. Whether in personal care products, electronics, or premium packaging, the look and feel of a product can convey value, identity, and purpose. Among the many aesthetic elements gaining traction, the color black has emerged as a powerful statement of elegance and minimalism. This design preference is fueling the global demand for a specialized material: black masterbatch.

As companies race to align with modern aesthetic expectations, the role of black masterbatch is expanding across industries. This article explores the trends behind that rise and why black remains one of the most strategic color choices in product design.

1. Understanding Black Masterbatch?

1.1. What is Black Masterbatch?

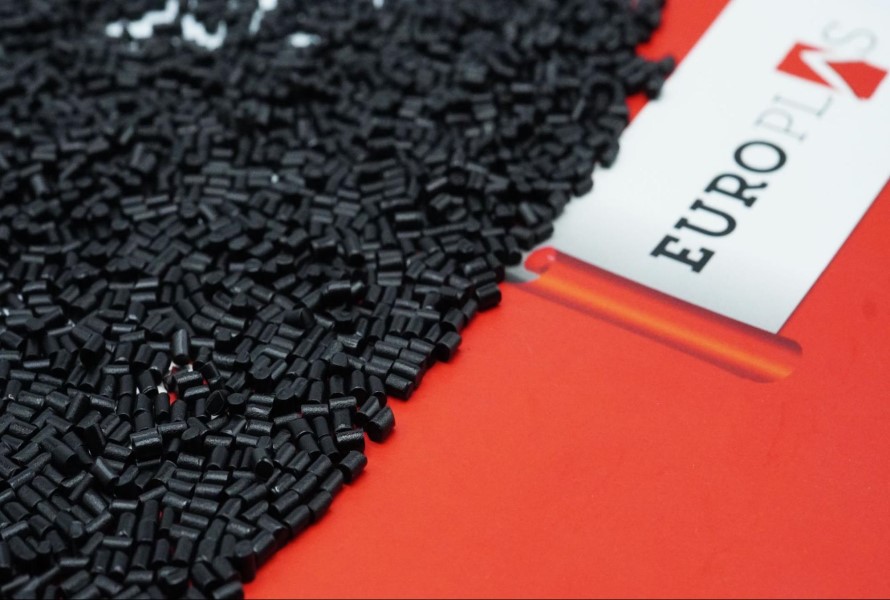

Black masterbatch is a concentrated blend of carbon black (or alternative black pigments), carrier resin, and additives. It is used to color plastic products by dispersing black pigment uniformly throughout the polymer matrix during production. This method ensures consistent coloration, superior UV protection, and excellent opacity.

There are various types of black masterbatch, typically differentiated by:

- Pigment type: traditional carbon black, NIR-detectable black, bio-based pigments

- Carrier resin: polyethylene (PE), polypropylene (PP), ABS, PET, etc.

- Application specificity: food-grade, weather-resistant, high-gloss, matte, etc.

Thanks to its versatility, black masterbatch can be tailored for different performance requirements — from basic coloration to advanced features like recyclability or anti-static properties.

1.2. Common Applications of Black Masterbatch

The use of black masterbatch spans multiple industries, including:

- Packaging: Black is used to create sleek, bold packaging for high-end cosmetics, gourmet foods, and personal care items.

- Automotive: Components like bumpers, interior trims, and dashboards frequently utilize black masterbatch for UV protection and consistency.

- Consumer Electronics: Devices such as headphones, chargers, and wearables often feature matte black finishes for a premium feel.

- Construction and Agriculture: Pipes, sheets, and greenhouse films benefit from the UV resistance and durability of black masterbatch.

- Household Products: From kitchen tools to storage bins, black is increasingly used for its clean, timeless look.

According to a report by Grand View Research, the global masterbatch market was valued at USD 6.60 billion in 2024 and is expected to grow at a CAGR of 6.6% from 2025 to 2030, with black masterbatch accounting for the largest share due to its widespread utility.

-(1).jpg)

Black masterbatch is a concentrated blend of carbon black (or alternative black pigments), carrier resin, and additives.

2. Aesthetic Appeal of the Color Black

2.1. The Psychology of Black in Branding and Packaging

Color influences perception — and black is among the most emotionally charged colors in marketing. Psychologically, black conveys:

- Luxury and exclusivity: Brands like Chanel and Apple use black to suggest sophistication.

- Power and authority: Black is often linked with strength and control.

- Simplicity and modernism: In minimalist design, black often serves as the anchor color.

A study by Colorcom Research found that people make subconscious judgments about a product within 90 seconds, and 62–90% of that judgment is based on color alone. This makes black a strategic asset in capturing attention and communicating brand identity quickly.

.jpg)

Color influences perception

2.2. Matte vs. Glossy Black Finishes

The rise of matte black has reshaped perceptions of luxury and modernism. Where glossy black once dominated in tech and packaging, matte finishes are now preferred for their understated elegance and tactile sophistication.

| Feature |

Matte Black |

Glossy Black |

| Aesthetic |

Understated, elegant |

Bold, reflective |

| Fingerprint visibility |

Low |

High |

| Surface feel |

Soft, textured |

Smooth, slick |

| Popular industries |

Cosmetics, electronics, fashion |

Packaging, automotive, household |

Comparison Table: Matte vs. Glossy Black Finishes

Matte finishes, especially when paired with soft-touch textures, are increasingly used in premium product packaging and tech accessories. This trend pushes demand for specialized black masterbatch that enables manufacturers to achieve consistent matte effects without post-production treatments.

2.3. The “Premium Look” in Retail Shelves

On the shelf, black stands out — not by screaming for attention, but by radiating class. Black packaging often signals “top-shelf” or “premium” in consumers’ minds. For example:

- Nespresso uses black capsules and packaging to highlight exclusivity.

- L'Oréal’s men’s grooming line is predominantly black to suggest strength and masculinity.

- Apple’s Space Gray (nearly black) line became a cultural symbol of design minimalism.

Research also confirms that using black can boost willingness to pay (WTP) due to its perceived premium and trustworthy associations. This aligns with increasing investment by consumer goods companies into packaging innovation using black masterbatch as a design core.

3. Trends in Product Design Influencing Black Masterbatch Usage

3.1. Rise of Minimalist and Monochrome Design

Minimalist aesthetics have dominated design culture in recent years, with an emphasis on simplicity, clean lines, and monochromatic color schemes. Black — being both neutral and bold — serves as a cornerstone in this design philosophy.

In product categories like cosmetics, electronics, and accessories, brands are reducing visual noise and relying on subtle detailing — often in black — to evoke premium appeal. For example:

- Glossier launched a limited black edition of its signature Balm Dotcom.

- Sony’s black PlayStation 5 accessories reflect a design language of control and power.

These choices are not just visual but strategic. Black enhances focus on form and materials, especially when used in matte or satin finishes.

Minimalist aesthetics have dominated design culture in recent years

3.2. Sustainability and Recyclability with Black Pigments

One of the traditional concerns with black masterbatch — especially those based on carbon black — is recyclability. Standard carbon black absorbs near-infrared (NIR) light, making it hard for recycling facilities to detect and sort. However, innovations have emerged:

- NIR-detectable black masterbatch enables black plastics to be sorted by optical sensors.

- Bio-based black pigments are being developed from organic waste like algae or industrial byproducts.

Brands seeking to balance aesthetic sophistication with sustainability are increasingly opting for these advanced black formulations. For instance, Unilever and Lush have adopted NIR-detectable black packaging to improve circularity in their supply chains.

3.3. Customization and Texture Enhancements

Modern product design is not only visual — it's tactile. As brands aim to create multi-sensory experiences, black masterbatch is being customized to deliver specific textures and finishes directly during the molding or extrusion process.

Common customizations include:

- Soft-touch finishes: Popular in personal care packaging and electronic accessories

- Embossed or debossed surfaces: Enhance grip and perceived value

- Satin or semi-matte effects: A balance between luxury and practicality

- Anti-fingerprint surfaces: Especially valuable for high-contact devices

Manufacturers are working closely with masterbatch suppliers to achieve these effects without extra coating layers, which reduces cost and improves sustainability.

4. Black Masterbatch as a Branding Strategy

4.1. Case Studies of Successful Black Branding

Several brands have built entire product identities around the color black:

- Chanel: From perfume to packaging, black is central to Chanel's timeless image.

- Nespresso: Premium coffee capsules in black denote intensity and richness.

- Dyson: Many of its hair tools and vacuums come in matte black for a high-tech aesthetic.

- OnePlus: Tech brand known for its sleek “Midnight Black” devices.

These examples prove that color is more than decoration — it’s identity.

4.2. Differentiation on the Shelf

In saturated markets, black stands out by not trying to. Its understated power differentiates products in:

- Cosmetics: Where competitors use bright color palettes

- Consumer tech: Against silver, white, or flashy hues

- Food packaging: As a signal of richness or clean eating

The contrast of a black surface allows minimalistic logos, text, or metallic accents to shine — all achievable with the right masterbatch blend.

4.3. Integration with Smart Packaging

As smart packaging (embedded QR codes, NFC tags, smart sensors) becomes more common, black backgrounds provide the perfect contrast for readable elements.

Manufacturers use black masterbatch that supports:

- High-resolution printing

- Laser marking

- Heat-resistant foil application

This allows brands to marry aesthetics with technology in one unified packaging solution.

5. How Manufacturers Can Leverage the Trend

If you’re a product designer or manufacturer, here are ways to capitalize on the growing demand for black masterbatch:

- Audit your product lines for where black can elevate perceived value

- Use black strategically in packaging or design to stand out

- Partner with trusted suppliers to develop tailored formulations

- Choose recyclable or sustainable black pigments if ESG is a priority

- Track seasonal and cultural trends: black is especially popular in luxury gifting and limited-edition lines

6. Conclusion

Black masterbatch is more than a colorant — it’s a strategic tool in modern branding, packaging, and product design. Aesthetic preferences across industries are leaning into minimalist, elegant, and tech-forward visuals — and black delivers all of these in one versatile tone. As consumers expect more in terms of both design and sustainability, manufacturers who embrace innovative black masterbatch solutions will position themselves ahead of the curve.

🟢 Now is the time to rethink the role of black — not just as a color, but as a brand asset.

7. Black masterbatch from EuroPlas

Black masterbatch is a mixture of carbon black, primary resin, and appropriate additives. It is known for UV resistance, endurance in harsh weather, and homogenous dispersion. EuroPlas offers a wide range of black masterbatches with mechanical properties suitable for various industries, including electronic, electrical, automotive, agriculture, construction, and packaging.

Our black masterbatch obtains different worldwide certificates. If you want to know more about various EuroPlas products, don't hesitate to contact us right away!