Created in the 1990s, COC (Cyclic Olefin Copolymer) and COP (Cyclic Olefin Polymer) polymers quickly gained attention for their exceptional clarity, rivaling even glass in their transparency. But their story doesn't end there.

But what truly sets these polymers apart is their versatility. COC and COP can adapt to diverse needs, finding homes in industries ranging from healthcare and electronics to aerospace and automotive. From life-saving medical devices to high-tech displays, these polymers are making their mark on the modern world.

In this article, we'll explore their diverse uses, highlighting the benefits they offer across various sectors. So, get ready to discover the hidden potential of these remarkable polymers!

1. Comparison between COC and COP

1.1. Availability and cost

COCs, due to their slightly simpler composition, are often less expensive than their more expensive COP cousins. However, this does not imply that they are inexpensive by any means. Both materials are considered high-performance, so expect them to be more expensive than standard plastics.

COCs have a modest advantage in terms of availability. They've been around longer and have more suppliers. Major chemical companies like DuPont and Topas specialize in COC production, while COP production is still dominated by a few key players like Zeon Corporation and Mitsui Chemicals.

1.2. Optical properties

Both COC and COP are masters of transparency, allowing light to pass through with incredible clarity. While COPs have superior transparency, COCs are still significantly more transparent than many other commonly used polymers like PET or PMMA. This makes them suitable for various applications requiring good optical clarity.

1.3. Mechanical properties

Strength and durability are essential qualities for many applications, and both COC and COP deliver in spades. They are both incredibly strong and resistant to impact, making them ideal for structural components and demanding environments. However, COP edges out COC slightly in terms of stiffness, making it the clear winner for applications requiring unwavering rigidity.

1.4. Chemical properties

COC and COP exhibit exceptional chemical resistance, including acids, bases, and organic solvents. Medical devices and food packaging will make the best use of COC and COP since they require good chemical compatibility. COC, on the other hand, may be more resistant to strong acids and oxidizing agents than COP.

1.5. Thermal properties

COC and COP can maintain their properties at high temperatures exceeding 150°C. However, COP generally possesses a higher heat deflection temperature (HDT) compared to COC, approximately 10°C to 30°C, indicating its capacity to endure higher temperatures without distortion.

Let us proceed with this comparison chart of key differences between COC and COP.

Property

|

COC

|

COP |

Composition

|

Primarily cycloolefin monomers, with small amounts of ethylene (0-5%) |

Primarily cycloolefin monomers, with no or minimal ethylene content (0-1%)

|

Melting point (°C)

|

Lower (typically 160-200°C) |

Higher than COC (typically 200-220°C)

|

| Transparency |

High (>90% light transmission) |

Slightly higher than COC (>94% light transmission)

|

| Strength (MPa) |

35-60

|

40-70 |

Stiffness (GPa)

|

2-3

|

2.5-3.5 |

Thermal stability (HDT °C)

|

High (140-170)

|

Higher than COC (180-200) |

Cost (USD/kg)

|

5-10

|

10-15 |

2. Top applications of COC and COP polymers

2.1. Medical devices and pharmaceutical

Enabling visibility in critical procedures with COC polymers in medical devices

Syringes and vials: The great transparency of COC provides for clear visibility of the contents, does not react with pharmaceuticals, and is safe for use with biological substances. This provides a precise dose and shields the drug from potentially dangerous chemicals.

Medical instruments: Surgeons need tools they can rely on. COP steps in with its high performance, allowing for precise surgical instruments that can withstand repeated use and sterilization.

Diagnostic tools: These materials are being used to develop personalized medicine solutions, which will allow doctors to tailor therapies to particular patients. Their excellent optical clarity enables for clear vision while remaining unaffected by the body's tissues and fluids.

Pharmaceutical packaging: Pharmaceutical packaging: Their high barrier traits keep sensitive drugs safe from moisture, oxygen, and other pollutants. Furthermore, high transparency allows for better inspection of the contents and is tamper-evident, ensuring medicine safety.

2.2. Food packaging

COC polymers are changing food packaging, ensuring freshness and visibility

Blister packs: Sleek, transparent packages that perfectly formed trays cradling your delicious cookies.COC keeps your food safe from moisture, oxygen, and other elements that can spoil its taste and freshness.

Push-through packaging: COP ensures your packages are strong enough to maintain their shape while allowing you to easily access your treats.

Food containers: COC and COP exceptional barrier properties keep food fresher for longer, while ensuring your food stays safe from any unwanted interactions with the packaging.

Food processing equipment: From conveyor belts to mixing tanks, these polymers offer the perfect blend of chemical resistance, heat resistance, and ease of cleaning, ensuring top-notch hygiene and food safety.

Storage containers and liners: COC and COP offer superior barrier properties that help keep food fresh for longer, while their antimicrobial properties provide an extra layer of protection. Additionally, their lightweight nature reduces transportation costs and environmental impact.

2.3. Optical applications

Bending the boundaries of technology with COP polymer smartwatch

Lenses: Capturing breathtaking landscapes or zooming in on microscopic details with unparalleled clarity. COC and COP, especially COP with its superior transparency, make this possible. They are used in lenses for cameras by capturing stunning high-resolution photos and videos with exceptional sharpness and color accuracy. Or microscopes, with crystal-clear images, revealing intricate details invisible to the naked eye.

Light guides: Need to transmit light efficiently and precisely? COC and COP high transparency allows light to travel with minimal loss, making them ideal for LCD screens and OLED panels to deliver vibrant colors and stunning visuals.

Optical films: From protecting your phone screen from scratches to reducing glare on eyeglasses, COC and COP are everywhere. With anti-reflective coatings, say goodbye to annoying reflections on your smartphone or tablet screen with these special coatings.

2.4. Electronics and semiconductors

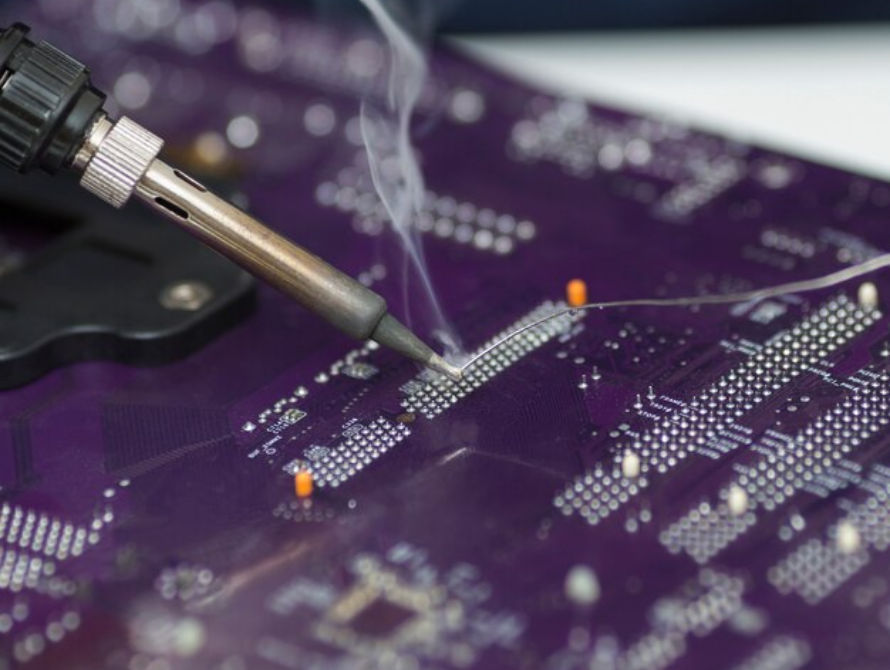

COP polymers in creating customized circuits on demand

Circuit boards and connectors: Electronics rely on intricate networks of circuits and connections. COC and COP, with their excellent dielectric strength and chemical resistance, ensure these connections are reliable and long-lasting.

Semiconductor packaging: Semiconductors are the heart and soul of modern electronics, and protecting them is critical. COC's low thermal expansion and exceptional chemical resistance make it an ideal material for encapsulating and protecting these sensitive components. This ensures they operate at peak performance for longer, even under harsh conditions.

High-frequency applications and flexible electronics: COC and COP are paving the way for the next generation of electronics. Their unique properties enable the creation of flexible circuit boards for wearables and other innovative devices. Additionally, their high-frequency performance makes them perfect for cutting-edge applications like 5G technology and beyond.

Encapsulation and protection of chips: COC forms a protective shield around delicate semiconductor chips, safeguarding them from environmental threats like moisture and dust. This ensures the chips remain stable and reliable, leading to longer device lifespans and more dependable performance.

2.5. Automotive

COP polymers in automotive help enhance safety and overall performance

Headlights and taillights: Say goodbye to bulky, fragile glass lenses. COC and COP polymers offer unmatched shatterproof qualities, making them ideal for headlights and taillights that can withstand bumps and jolts without shattering. Additionally, their superior UV resistance ensures they won't yellow or fade over time, keeping your car looking new for longer.

Structural parts: Underneath the sleek exterior, COC and COP polymers are playing a crucial role in making cars lighter and more fuel-efficient. These materials offer incredible strength-to-weight ratios, allowing manufacturers to replace heavier metal components without compromising on performance. This translates to improved fuel economy, reduced emissions, and a more enjoyable driving experience.

2.6. Aerospace

Allow pilots to feel at peace even when flying in adverse conditions

Interior panels and windows: Every gram counts when it comes to aircraft design. COC and COP polymers are helping airlines save weight and fuel by replacing traditional materials in interior panels and windows. These lightweight materials offer excellent strength and durability, ensuring passenger safety and comfort without adding unnecessary weight.

Instrument panels: From vital flight information to critical warning systems, clear and accurate instrument displays are crucial for safe navigation. COC and COP polymers provide exceptional optical clarity, ensuring pilots have the best possible view of crucial information, even in challenging lighting conditions.

3. Advantages and Limitations of COC/COP Polymers

3.1. Advantages

- Crystal-clear: Unbeatable transparency for applications like eyeglasses and microscopes.

- Chemical champions: Resilient against harsh chemicals, ideal for medical devices and food packaging.

- Lightweight powerhouses: Strong yet light, perfect for aerospace and automotive parts.

- Heat-resistant: Stable at high temperatures, suitable for demanding electronics and medical devices.

- Biocompatible: Safe for medical devices and food packaging.

- Easy to work with: Easy to process and fabricate into various shapes and forms.

3.2. Limitations

- Higher price: Costlier than some traditional materials.

- Sun sensitivity: Susceptible to UV degradation, but can be protected with additives.

- Limited availability: Availability might be limited depending on the specific grade and application.

4. Market trends and future prospects for COC and COP polymers

Harvesting the power of the sun with COP polymers solar panel

The remarkable properties of COC and COP polymers, combined with rapid technological advancements and burgeoning consumer demand, are poised to revolutionize various industries. These polymers offer exceptional transparency, chemical resistance, lightweight strength, heat stability, and biocompatibility, making them ideal for a diverse range of applications.

Fueled by the growth of consumer electronics like smartphones, wearables, and smart devices, the demand for miniaturization and portability is driving innovation. COC and COP polymers are perfectly suited to this trend, enabling the development of devices that are smaller, lighter, and more compact.

Sustainability and environmental concerns are also playing a significant role in driving the use of COC and COP polymers. These materials are recyclable and resource-efficient, contributing to a more sustainable future.

With their endless possibilities, COC and COP polymers are undoubtedly changing the world, holding even more exciting possibilities with innovative products like:

- Flexible displays: Imagine foldable smartphones, wearable displays, and even rollable TVs revolutionizing the way we consume information. Big brands like Samsung and LG are already investing heavily in this technology.

- Wearable electronics: Smart clothing seamlessly integrated with technology for health monitoring, communication, and entertainment is becoming a reality, with companies like Apple and Google leading the charge.

- Printed electronics: Customized sensors and circuits created on demand, reducing waste and increasing accessibility, are opening doors for innovative applications in various fields.

- Biocompatible implants: Sensors, monitoring devices, and even personalized medicine delivered through implantable devices are revolutionizing healthcare, with companies like Medtronic and Abbott Laboratories actively developing these technologies.

- Next-generation solar cells: Offering improved efficiency and flexibility, these solar cells have the potential to revolutionize the renewable energy landscape, with companies like Tesla and Panasonic heavily invested in their development.

5. Conclusion

From transparent eyeglasses to high-tech OLED displays, COC and COP polymers are quietly taking over diverse industries with their incredible versatility. Their unique blend of transparency, strength, chemical resistance, and thermal stability opens doors to countless possibilities.

If you're curious about the ever-evolving world of plastics and want to delve deeper into the exciting world of plastic solutions, head over to the

EuroPlas blog! We're constantly updating our content with informative articles, industry insights, and expert tips to help you stay ahead of the curve.