PLA plastic has much higher applicability than traditional plastic materials because of its biodegradability. In this article, EuroPlas will analyze in detail the competitive advantages as well as practical applications of PLA plastic materials in human life. Check out the article now so you don't miss out on information about one of the best biodegradable plastic materials today!

The applicability of PLA is highly appreciated by manufacturers.

1. Definition of PLA

PLA plastic is classified into the thermoplastic group. The source of input materials for PLA plastic production is mostly environmentally friendly renewable materials. In particular, they will come from plants such as: Cassava, potato starch, sugarcane. In addition, polylactic acid (PLA) and polyhydroxyalkanoate (PHA) are the two main chemical components that make up PLA biodegradable plastic.

Thanks to its natural fuel composition, PLA plastic has been and is holding a certain advantage in the market compared to other petrochemical or chemical plastic materials such as: ABS (Acrylonitrile butadiene styrene) or PVA (Polyvinyl Alcohol). In particular, the ability to self-decompose stably and not affect the health of consumers has greatly enhanced the practicality of this type of plastic in life.

Product life cycle of PLA plastic

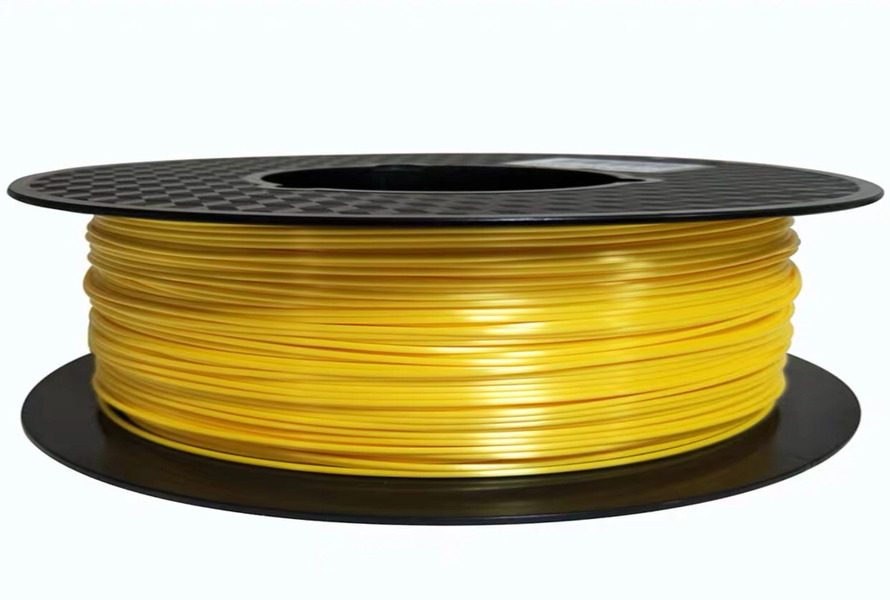

Currently, most PLA plastics are applied by manufacturers in a variety of fields, but there are also some key industries such as: FDM 3D printing, household appliances, restaurants & hotels, electronic equipment or even the field of cosmetic surgery. In addition, the natural chemical structure of PLA plastics allows them to combine well with colorant resins during processing to create a variety of product lines. This also positively affects the price of PLA plastic on the market.

This is just basic information about the definition and strengths of PLA plastic. In the next part, EuroPlas will help customers understand the importance of PLA plastic in life.

2. How important is PLA plastic to human life?

The importance of PLA plastic is proven through its sustainable biodegradability as well as its practical applications in various areas of life. To better understand the importance of PLA plastic, EuroPlas will analyze its applications and advantages.

2.1. Applications of PLA plastic in life

-

Medical field: The characteristics of PLA plastic are high biocompatibility, biodegradability, heat treatment and high mechanical strength, solubility in organic solvents, so it is widely used in drug delivery materials. For example, PLA is used to deliver tetanus treatment, or support insulin penetration in the form of sprays to treat diabetes. In addition, PLA plastic materials are also used to manufacture medical devices in surgery such as sutures, disposable infusion devices, and bone shaping bars. It can be said that to be used in medicine, the material must meet the highest standards and undergo many strict inspection lines. Therefore, customers can see the importance of PLA plastic materials to humanity.

-

Automotive transport sector: PLA plastic weighs quite light, about 750g, so it is used to produce equipment and automotive components. For example: Toyota uses PLA composite and kenaf fiber to make spare tires and research to produce floor mats, handles, and seats. Ford uses PLA composite to make car arch systems and carpets. Or PLA plastic is combined with Nylon 6 to produce car mats for the Mitsubishi brand.

PLA plastic is a stable biodegradable plastic.

-

Technology - electronics sector: Because PLA plastic's heat resistance is quite good in the range of 0 - 60 degrees Celsius, it is used to produce electronic components. Therefore, PLA plastic is an indispensable material in the production of phone cases, computer frames, connection ports and charging cable covers. Currently, there are still many famous corporations using PLA plastic such as Samsung, NEC Group of Japan or Mitsubishi. Besides, PLA plastic is also applied in the 3D printing industry because of its soft, durable, heat-resistant and easy-to-combine plastic with other materials. The 3D printing and electronic components fields are closely related to each other, so PLA plastic materials further prove their importance.

-

Agricultural field: PLA plastic originates from biological preparations, so they are very environmentally friendly and do not affect the health of consumers. In the agricultural field, PLA plastic is produced into biological coatings to increase the growth time of plants and fruits in the most natural and safe way. In addition, the PLA biofilm also has antibacterial effects, preventing insects and bacteria from growing, negatively affecting plants. In particular, the PLA biofilm has high durability, the ability to withstand weather and environmental impacts, helping plants increase their resistance.

-

Household products: PLA plastic is not only heat-resistant and durable, but also antibacterial and unaffected by the environment. Therefore, PLA plastic appears in everyday plastic products such as trays, food containers, supermarket bags, plates, cups, spoons. In particular, the combination of PLA plastic with reinforcing agents such as bentonite and microcrystalline cellulose and silicate coatings further enhances the physical and chemical properties of this material. The mixture will be resistant to UV rays, antibacterial and used as food wrap.

PLA is used in everyday products

Customers can see the importance of PLA plastic in life through their versatility in each separate product line. Next, EuroPlas will review the most outstanding advantages of PLA plastic.

2.2. Advantages of PLA plastic materials.

-

The origin meets the standards of nature, plants such as: cassava, sugarcane, starch, cornstarch, ... helping PLA become one of the most popular bioplastics today.

-

Compared with the decomposition time of traditional plastic materials, PLA has many advantages. Their decomposition time is only about a few months or years. On the contrary, traditional plastics can take up to hundreds of years to completely decompose. Therefore, PLA is an effective solution, aiming to green the plastic industry and completely replace conventional plastic materials. This is the bioplastic trend of the future.

-

Moreover, the impressive point of PLA plastic is that it can decompose into organic fertilizer, contributing to supporting the agricultural sector. In addition, the chemical and physical structure formed from natural materials makes them easy to combine with other plastics and colorants during product processing. Almost the entire life cycle of PLA plastic does not affect the quality of the surrounding environment, they appear not only in the agricultural sector but also in the medical sector. These are specialized fields that require the highest quality of raw materials because they can directly affect the health of consumers.

-

The physical properties of PLA are equally impressive. Their melting point reaches 160 degrees Celsius. In terms of tensile strength and flexibility, PLA is inferior to PE (Polyethylene) or PVC (Polyvinyl Chloride). However, if we consider the ability to decompose, PLA is far superior to traditional materials.

2.3. Disadvantages of PLA plastic

The production process of PLA plastic depends heavily on suppliers of natural products such as: sugarcane, potatoes, corn, ... Therefore, factories producing bioplastics in general and PLA in particular are often built near these farms.=

Although PLA plastic is more biodegradable than traditional plastics, the conditions for them to form this process are extremely difficult. All microbiological, environmental, temperature factors, etc. will directly affect the biodegradation results of PLA plastic. If the factors occur according to the standard, this process is extremely easy and vice versa.

The PLA plastic recycling process is also not easy when it must be carried out separately, otherwise it will affect other raw materials. In general, bioplastics such as PLA require very high technical skills to produce the best finished products.

Finally, for difficult technical plastics, production costs will increase significantly because units not only invest in modern equipment but also have a team of experienced staff and thorough understanding of the materials. Meanwhile, traditional plastic materials such as PE, PP, PVC or PA are produced with a simple cycle, low cost and do not require too much technical requirements.

These are weaknesses that can be overcome to help PLA plastic develop and become more popular in the future.

3. Introduction to EuroPlas' bioplastic line

BiONext is a bioplastic product developed by EuroPlas, a leading company in the plastics industry. BiONext is an environmentally friendly alternative to traditional plastic products, as it is derived from sustainable biomass sources such as PLA, PHA, plants and vegetables (corn, palm oil, potatoes) or fossil fuels (PBAT).

EuroPlas bioplastics have similar properties to traditional plastics but have the added benefit of being environmentally friendly and reducing carbon emissions. Our products are a sustainable and responsible alternative to conventional plastics, helping to reduce the environmental impact of plastic waste and promote a more circular economy.

In particular, the practicality of EuroPlas's BIONext bioplastic line is not inferior to other products on the market. They are flexibly applied in many fields including food packaging, bags, utensils and even automotive components. In addition, products made from BIONext thermoset are also very diverse because this material is heat-resistant and easy to shape during processing.

4. Conclusion

Through the above article, EuroPlas has demonstrated the importance and influence of PLA plastic in life. This material has been aiming to green the plastic industry, using 100% bioplastic in all fields. PLA plastic will continue to actively contribute to the development of the global plastic industry and key areas in society to bring customers the safest and highest quality products. Please continue to follow and accompany EuroPlas to update news about the plastic market!