European Plastic Company(EuP), a pioneering Vietnamese company in the development of Bioplastic Compound for industrial production applications.

Bioplastic is a topic that has been talked about a lot in recent years as an effective solution to reduce plastic waste and minimize some negative impacts on the environment.

BioNext - Bioplastic compounds from EuP

BioNext - Bioplastic compounds from EuP

Using renewable resources

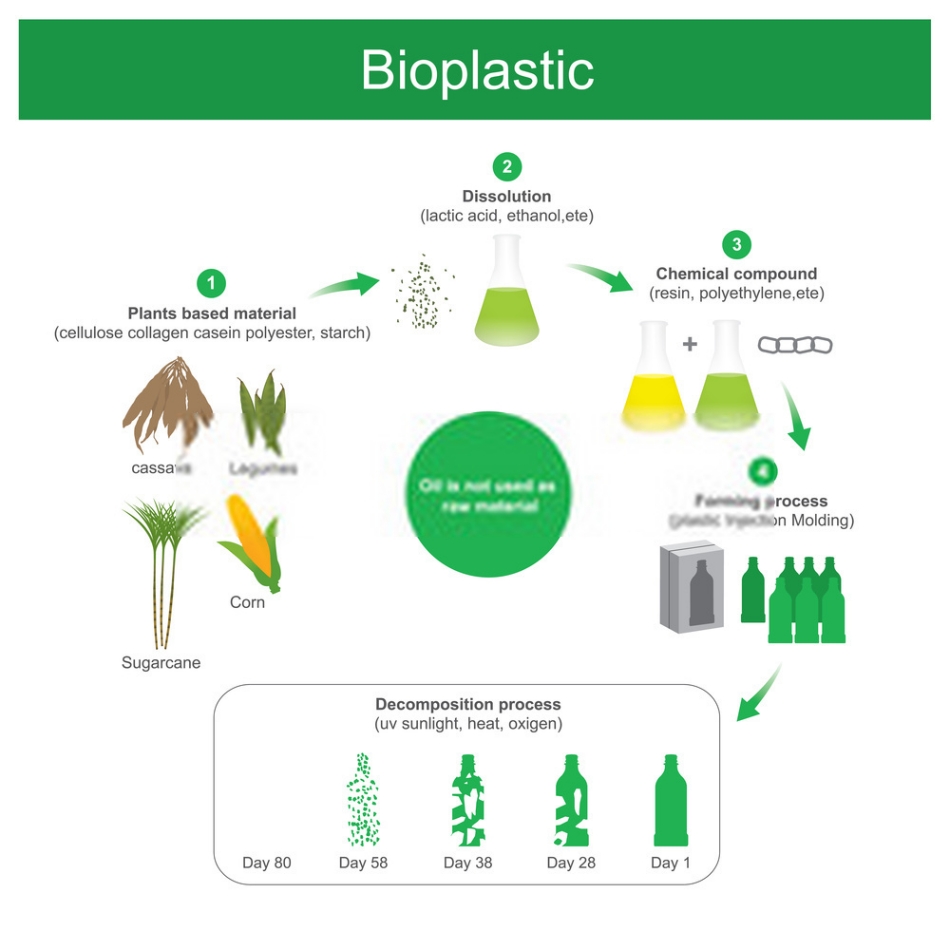

EuP's bioplastic material, branded as BiONEXT, is derived from environmentally friendly materials such as corn starch, potato, cassava, etc. This is a renewable source of raw materials depending on the seasonal cycle of the year.

It can be seen that the shift from fossil fuel sources to renewable materials is a huge step forward for humans, opening the path to sustainable development.

Because fossil fuel resources will be increasingly scarce and non-renewable in our time, the orientation of using short-life renewable raw materials is an extremely potential solution to bring about balanced and sustainable development.

Science and technology are increasingly developing and have been gradually solving the transformation of this source of raw materials.

Market orientation of BiONext

First of all, we cannot deny the great benefits of the plastic industry that have promoted economic and social development over the past few decades.

However, plastic itself also causes many negative impacts on the environment. This situation has been warned everywhere. A number of countries have taken action to ban single-use plastic products, because they find them to be a big cause of plastic pollution worldwide.

Understanding that situation, EuP has researched and launched BiONEXT bioplastic material to meet this demand. Products made from BiONEXT will be biodegradable or biodegrade quickly by the composting process.

The result of the decomposition process will produce water, carbon dioxide and humus. Currently, BiONEXT develops 3 main lines targeting three areas.

One is the BiONEXT 400 and 500 material lines. This is a group of materials for blowing biofilms, flexible packaging, having enough toughness and biodegradability.

The second is the BiONEXT 152 material line aimed at the injection molding product segment to create biodegradable dental cups, spoons, forks or toothpicks.

Third is the BiONext 102 series, designed for the extrusion industry that creates biodegradable straws

BiONext's Opportunities and Challenges

EuP successfully developed the bioplastic material BiONEXT at the right time for the 2019 K-fair exhibition. This was a golden opportunity for EuP to introduce to the world at the end of October 2019. The event attracted a large number of customers and partners to visit the exhibition.

The product is made from bio-plastic material, which is both environmentally friendly and convenient in daily life, and is assessed to have great potential in gradually replacing fossil plastic products. .

In addition, with many new policies being issued on environmental issues in general, and restrictive policies for the plastic industry in particular, it has opened the door to development for bioplastics like BiONEXT worldwide.

Another factor to mention is Vietnam. Our country has been a leader in exporting rice and a number of agricultural products over the past decade. From a different perspective, it will help Vietnamese businesses be proactive about renewable resources. Taking advantage of this source of raw materials will bring great advantages to BiONEXT bioplastics.

The biggest challenge for bioplastic materials like BiONEXT at present is the technical and cost factors. These two factors are directly related.

To create BiONEXT, it is necessary to invest in research and development. Manufacturers need to invest in equipment and modern technology to convert materials from renewable sources into biological materials with the required properties in each final product.

This has resulted in higher prices for biomaterials than for fossil-based materials that are common today. In the future, when technical technology is transferred and more widespread, and it is easier to convert agricultural waste products, the cost of bioplastic production can be optimized.

Combined with the scarcity of fossil raw materials, Biomaterials such as BiONEXT are considered to be the next inevitable process of the market.

Eco-friendly properties of BiONext

BiONEXT is environmentally friendly because it is the raw material to create biodegradable plastic products. Biodegradation is a process thanks to the action of microorganisms, which, under natural conditions, make the product decompose into water, carbon dioxide and humus.

Factors in the natural environment such as location, humidity, temperature, different amount of microorganisms... will bring different decomposition results. BiONEXT is designed so that the end products are biodegradable within 12 months of being disposed of in the general environment.

The biodegradation process will be accelerated by industrial or home composting methods and at the same time, humus residue is obtained as organic fertilizer in agriculture.

This is the “Compost” method. This method is very popular in developed countries around the world.

Biodegradable products labeled “Compostable” will be collected for treatment in factories (Compost Industrial) or in separate compost bins in the garden in households (Compost Home). The humus residue obtained from the “compost” process is used as fertilizer for plants.

The closed cycle based on the ecosystem is the factor that creates the sustainable development of bioplastics.

For more details and to get samples of BiONext from EuroPlas, do not hesitate to contact us!