As resources become increasingly depleted and human needs increase, sustainability is a vital issue for the global food business. Bioplastic packaging has become increasingly popular thanks to its sustainability and environmental friendliness. In this article, we will look at the different types of bioplastic packaging available and the benefits they offer.

1. Overview of bioplastic packaging

Bioplastic packaging can be used in various applications, from food and beverage products to medical supplies and electronics. This type of packaging is also more cost-effective than traditional plastic packaging, making it an attractive option for businesses looking to reduce their carbon footprint. Here are the two typical packaging applications of bioplastics.

Read more: What are bioplastics made from? Materials to make bioplastics

1.1. Food packaging

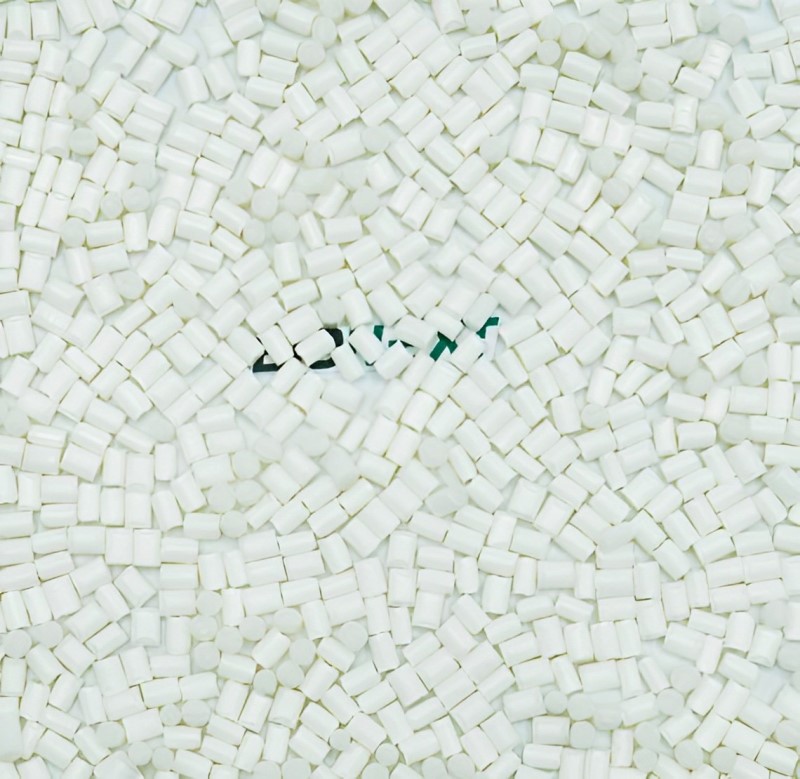

Bioplastics are usually made from renewable resources such as corn, sugar cane, and other plant-based materials. Bioplastic packaging stores food products protects them from damage and extends their shelf life without releasing toxic chemicals that can affect the food quality. It is also lightweight and cost-effective compared to traditional plastic packaging.

Since manufacturers use bioplastic for food packaging, the packaging is 100% compostable and biodegradable, meaning it does not produce any harmful waste or toxins that can harm the environment. It is also recyclable for further use in other products or materials.

1.2. Cosmetic packaging

Bio-PE (Polyethylene), Bio-PET(Polyethylene terephthalate), and other biobased plastic are appropriate alternatives for producing bottles with tubes, screw tops, pump dispensers, or hinged closures. Bioplastic cosmetic packaging is especially strong, chemically resistant, readily colored, product-safe, and 100% recyclable. Moreover, using bioplastics in packaging conserves fossil resources, avoiding damaging greenhouse emissions.

2. Advantages of bioplastic packaging

Bioplastic packaging offers several advantages over traditional plastic packaging:

- Less plastic pollution: It can be composted or recycled, reducing waste sent to landfills.

- Easier to be transported: Bioplastic packaging is lightweight and strong, making it ideal for transporting goods over long distances without adding additional weight to the product.

- Less harm to the environment: It also requires less energy to produce than traditional plastics, which can lead to cost savings for businesses and reduce carbon footprint.

- Improved product safety: Biodegradable packaging usually derives from biomass ingredients. Consequently, they contain no toxic compounds and pose no dangers to their consumers.

- Reduce fossil fuels exploitation: Plastic production accounts for more than 8% of global fossil fuel production. Using bioplastics as an alternative helps decrease the number of fossil fuels used.

- Can boost soil fertility: Biodegradable packaging products are safe to deposit in open areas since they improve soil fertility. They will decay and become part of the soil.

3. Disadvantages of bioplastic packaging

Despite all of the benefits, bioplastic has certain drawbacks that need to be improved:

- May have a higher price: Bioplastics are often more expensive than their oil-based equivalents. They are often two to three times more expensive than major traditional polymers as their manufacture needs to be improved by low yields and high costs. This disadvantage should lessen as manufacturing operations grow and benefit from economies of scale.

- Lack of resources: Crop-based bioplastics are weather dependent and need fertile soil, water, and fertilizers. This means that the availability of raw materials for bioplastics is vulnerable to natural occurrences such as drought.

- Shorter lifetime: Certain bioplastics have a shorter lifetime than oil-based polymers.

- Require facilities to decompose: Many bioplastics must follow a precise disposal protocol and require industrial composting to prevent being burnt or disposed of in a landfill. If local governments lack this equipment, bioplastics may be disposed of alongside regular rubbish and, in certain situations, do not degrade as quickly as the conventional.

4. The future of sustainable and eco-friendly packaging

Bioplastics are a novel approach to the world's concerns with traditional plastics. They're nearly indistinguishable from petroleum-based polymers but have many environmental advantages.

Bioplastic food packaging protects the planet's natural resources and provides consumers with additional alternatives for disposing of packaging responsibly, making it a significantly more environmentally friendly packaging solution.

Bioplastics for packaging markets account for a relatively tiny portion of the worldwide plastic packaging market value, but they are rapidly growing. While the potential market for bioplastics is enormous, consumption rates will be determined by companies' ability to expand production capacity quickly enough and at acceptable cost/performance ratios to fulfill demand.

5. BiONext - The ideal material for bioplastic packaging

BiONext is a bioplastic compound created exclusively by EuroPlas. It offers many advantages over traditional plastics, such as

- Eco-friendly and sustainable: This material decomposes in 12 months or less, minimizing its environmental footprint.

- High strength and flexibility: The material can meet the most rigorous standards of quality.

- All features in one material: BiONext helps save you time and money, no need to add many additives.

- Customizable to fit your product's requirements: Just let us know what you need, and we'll deliver the perfect tailored materials for your project.

BiONext is used in various industries, including electronics, automotive and transportation, home appliances, construction, fibers, and, most notably, food packaging. EuroPlas provides a variety of bioplastics: BiONext 102, BiONext 152, BiONext 400, BiONext 500, BiONext 600, and BiONext 700. Contact us for more details.