Color masterbatch is properly one of the most vital and widely-used material in manufacturing high-quality plastic products. Color masterbatch is mainly used with the purpose of creating colorful and eye-catching appearance for the final products, helping them cover the aesthetic requirements. The category of color masterbatches in EuP consists of a wide range of products, from simple and basic products such as white masterbatch and black masterbatch to other products complex colors and effects.

White masterbatch consists of high concentration (80%) of titanium dioxide, which helps the color masterbatch to achieve excellent dispersion, good heat resistance and thermal stability. TiO2 is considered to perform effectively in scattering light, contributing high opacity and improving lightness and brightness of the material it is mixed with. Moreover, titanium dioxide is also able to absorb UV light. This ability significantly affects the final product in the way which their durability, especially during weather conditions, is highly improved. Excellent mechanical properties (be able to withstand impacts and tear resistance) is another benefits of using this product. White masterbatch in the current markets is diverse in a wide range of types categorized based on the specific base resin it consists of, including PP, PE, PS, ABS and polyester. Thus it is widely applied in many fields such as blow molding, injection molding and high-end rotational molding.

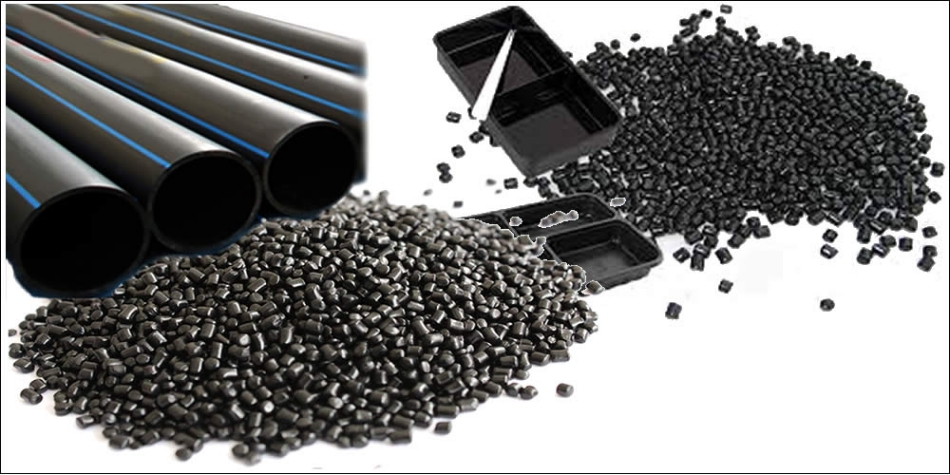

On the other hand, black masterbatch consists high amount of black carbon powder, which brought the black color to the masterbatch, base resins, functional additives and with or without fillers (such as talc, calcium carbonate powder). Black masterbatch is famous for its UV resistance and high endurance to harsh weather conditions. This color masterbatch also has homogenous dispersion which is suitable for applications in electronic and electrical devices (such as wires, cables, washing machine, vacuum cleaners, coffee machines, mixers, blenders, DVDs, TVs), automotive accessories, argicuture, construction industry (geomembranes, water tanks, water pipes) and packaging industries (especially safe for making packaging used in food and beverage industry).

In comparison to color master batch does not contain fillers, the calcium carbonate in those including them helps manufacturers save more production costs and gain more productivity, helps the products achieve better performance without causing negative impacts to the environment.

At EuP, we can produce any type

of color masterbatch that you

require. Our research team is willing to try our best to find out the best

solution with high-quality products that cater multitude of your requirements.

So whether you want white masterbatch, black masterbatch or any kind of

masterbatch, we are sure that you can find it at EuP. We guarantee that all

products with brand-name EuroPlas produced by EuP achieve excellent color

dispersion, stable performance and fine-smoothness since we applied the most

modern technology on the world and used machinery imported from Germany into

our productions.

EuP offers a wide range of color masterbatch with different color

options such as yellow, orange, red, pink, green, brown, blue, purple and

grey/silver which can be modified into various shades, hues (such as

transparent, , opaque, milky) and even with special effects (metallic, pearlite

sparkle, etc.). The color pigments are carefully selected to ensure chemical

resistance, color fastness, good printability and color stability during

different weather conditions. We paid efforts to generate desired formula for

specific products and usage purposes.