Cost Comparison: High Impact Polystyrene vs. Other Materials

1. What is High Impact Polystyrene?

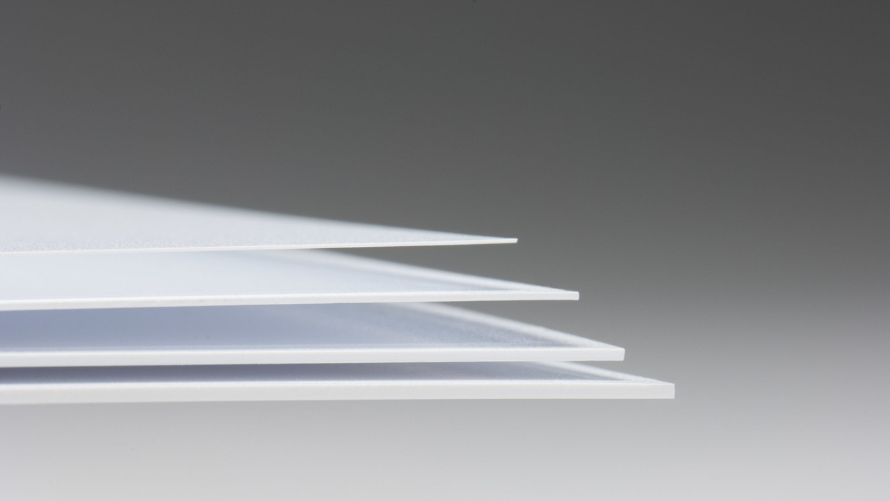

High impact polystyrene (HIPS) is a popular thermoplastic polymer known for its strength, ease of processing, and affordability. It combines the toughness of rubber with the rigidity of polystyrene, resulting in a material widely used in numerous applications, from packaging and consumer products to industrial parts.

Read more: Advantages and disadvantages of HIPS plastic - Best in class HIPS compounds

High impact polystyrene (HIPS) is a popular thermoplastic polymer known for its strength, ease of processing, and affordability.

2. Cost Factors of High Impact Polystyrene

2.1. Raw Material Cost

High impact polystyrene is generally cost-effective due to abundant raw materials such as styrene monomer. The global availability of styrene ensures stable pricing and reliability. Although petroleum-based fluctuations occasionally impact costs, overall stability makes HIPS a preferred choice for manufacturers.

2.2. Production Efficiency

HIPS has excellent processing characteristics, allowing manufacturers to benefit from faster cycle times, reduced energy consumption, and minimized waste. Its ease of molding, thermoforming, and extrusion contributes significantly to cost efficiency and high productivity.

2.3. Transportation and Storage

HIPS is lightweight, simplifying logistics and transportation costs. Its resistance to moisture and stable shelf-life reduces storage requirements, providing further cost advantages.

3. Comparison of High Impact Polystyrene vs. Alternative Materials

3.1. High Impact Polystyrene vs. ABS (Acrylonitrile Butadiene Styrene)

ABS shares similarities with high impact polystyrene, particularly in durability and versatility. However, ABS generally incurs higher production costs due to the complexity of its raw materials. ABS provides superior heat resistance and impact strength but at a notable price premium over HIPS, making HIPS more cost-effective for many non-critical applications.

Read more: HIPS vs. ABS Plastic: What Are The Differences?

3.2. High Impact Polystyrene vs. Polypropylene (PP)

Polypropylene is another widely-used thermoplastic known for being highly affordable. Compared to high impact polystyrene, PP offers slightly lower rigidity and surface quality but superior chemical resistance. While PP can be cheaper depending on market conditions, HIPS remains competitively priced due to its balanced performance and ease of manufacturing.

3.3. High Impact Polystyrene vs. Polyethylene (PE)

Polyethylene is highly affordable and widely available. However, compared to high impact polystyrene, PE is generally softer, less rigid, and less suitable for applications requiring structural integrity or detailed molding. Although polyethylene may present initial cost savings, the limitations in performance and durability can lead to higher long-term costs.

3.4. High Impact Polystyrene vs. Polycarbonate (PC)

Polycarbonate is significantly more expensive than HIPS due to its superior strength, transparency, and impact resistance. This premium material is often chosen for high-performance applications such as automotive or electronics. However, for general-use scenarios where extreme performance isn't required, high impact polystyrene provides a more cost-effective alternative without sacrificing basic performance attributes.

4. Specific Cost Comparison (2024 Prices)

In 2024, the average prices per kilogram for high impact polystyrene (HIPS) and its alternative materials were:

- High Impact Polystyrene (HIPS): Approximately $1.30 per kg

- Acrylonitrile Butadiene Styrene (ABS): Approximately $1.97 per kg

- Polypropylene (PP): Approximately $1.20 per kg

- Polyethylene (PE): Approximately $1.00 to $1.35 per kg

- Polycarbonate (PC): Approximately $2.25 per kg

These prices are indicative and can vary based on order quantity, supplier, and market conditions.

High Impact Polystyrene (HIPS) has the cost of approximately $1.30 per kg.

5. Overall Cost Benefits of Choosing High Impact Polystyrene

5.1. Versatility and Applicability

High impact polystyrene is versatile, making it suitable for diverse applications including packaging, signage, and automotive parts. Its combination of ease-of-use, low cost, and good mechanical properties enables manufacturers to reduce overall production expenses without compromising quality.

5.2. Durability and Longevity

Despite being economical, HIPS offers impressive durability and resistance to impact. This balance of affordability and toughness makes high impact polystyrene a strategic choice for long-term use, reducing replacement frequencies and lifecycle costs.

5.3. Cost Stability

Thanks to its well-established supply chain and global availability, high impact polystyrene demonstrates exceptional cost stability compared to more volatile alternatives. Manufacturers benefit from predictable budgeting and lower risk exposure related to market fluctuations.

High impact polystyrene is versatile, making it suitable for diverse applications including packaging, signage, and automotive parts.

6. Conclusion: Making the Right Material Choice

When comparing the overall cost-effectiveness of high impact polystyrene with alternative materials, several factors emerge clearly: affordability, ease of production, versatility, and environmental friendliness. For most general applications, HIPS offers substantial economic advantages without significantly compromising performance or environmental goals.

7. About EuroPlas

EuroPlas is a leading manufacturer and supplier of plastic masterbatch and compounds, including HIPS filler masterbatch, dedicated to delivering innovative solutions in the plastic industry. With extensive expertise in high-quality products, including filler masterbatch, color masterbatch, plastic additives, engineering plastic compounds, biofillers, and bioplastic compounds, EuroPlas helps clients optimize their production processes and enhance product performance.

Learn more about our products and explore further articles on our blog. For questions about HIPS filler masterbatch or other products, please contact us via email or telephone!