Cross linked polyethylene is a versatile material with a wide range of applications across various industries thanks to its unique properties. In this article, we will explore cross-linked polyethylene, its key features, and its typical uses.

1. What is cross linked polyethylene?

Cross linked polyethylene, commonly known as XLPE (or PEX), is a type of thermoplastic polymer. It is created by subjecting regular polyethylene to cross-linking, which involves connecting the polymer chains to form a three-dimensional network.

Cross linked polyethylene is created through a process called cross-linking, where polyethylene is exposed to heat and pressure or radiation. This process forms covalent bonds between the polymer chains, resulting in a material with improved strength, flexibility, and resistance to environmental factors.

Cross linked polyethylene is commonly known as XLPE or PEX

The cross-linking process improves polyethylene's mechanical, thermal, and chemical properties, making it more durable, resistant to heat and pressure, and less susceptible to chemical degradation. It also increases the flexibility and impact resistance of the material.

Different methods of cross-linking polyethylene include chemical cross-linking, irradiation, and physical cross-linking. Chemical cross-linking involves using a cross-linking agent, such as peroxide, to initiate the reaction that forms the cross-links between polymer chains.

Irradiation involves exposing polyethylene to high-energy radiation, such as gamma rays or electron beams, which causes the polymer chains to cross-link. On the other hand, physical cross-linking relies on heat or pressure to induce the cross-linking of the polymer chains.

2. Key features of XLPE cross linked polyethylene

Cross linked polyethylene is a thermosetting polymer with several remarkable properties that make it suitable for various applications.

2.1 High Temperature Resistance

One of XLPE's primary advantages is its exceptional temperature resistance. It exhibits excellent thermal stability and can withstand high temperatures without degradation, making it suitable for applications in hot and harsh environments. Crosslinked polyethylene can operate continuously at temperatures up to 90°C and withstand short-term temperature spikes up to 130°C. (Source: Polyethylene Nanocomposites for Power Cable Insulations)

Polyethylene cross linked can withstand high temperature

2.2 Chemical Resistance

Another notable feature of cross linked polyethylene is its chemical resistance. XLPE has extensive chemical resistance capabilities without the need for high-cost coatings. This material is highly resistant to acids, alkalis, solvents, and oils.

This property makes it suitable for applications where exposure to corrosive substances is a concern. Moreover, cross linked polyethylene pipes have low permeability, reducing the risk of contamination by external elements and ensuring the integrity of fluid transportation systems.

2.3 Electrical Insulation

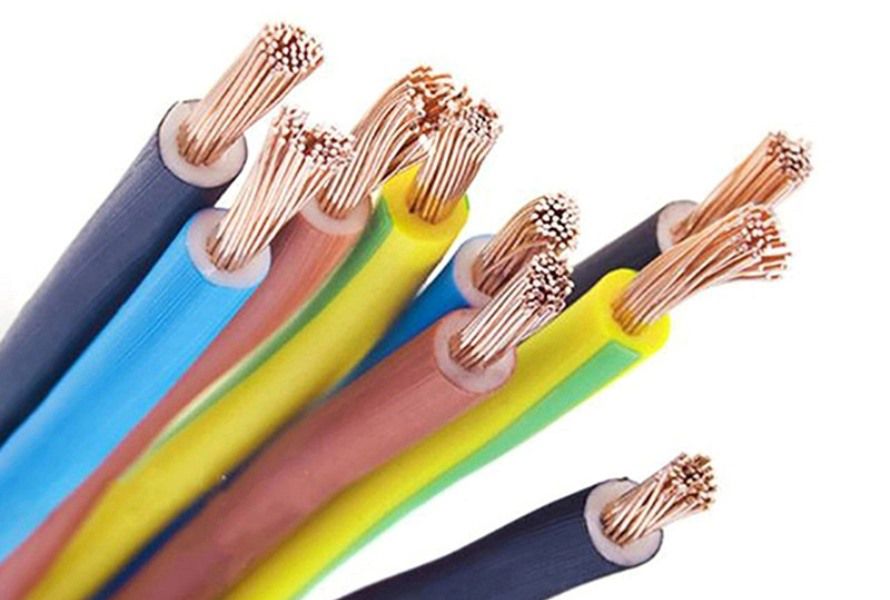

Crosslinked polyethylene has excellent electrical insulation properties, making it widely used to manufacture cables and wires. It offers low dielectric constant and high dielectric strength, allowing efficient electrical power transmission while minimizing energy losses.

Crosslinked polyethylene has excellent elecstrical insulation properties

2.4 Low Water Absorption

Crosslinked polyethylene has low water absorption characteristics, making it resistant to moisture and preventing the deterioration of its electrical and mechanical properties even in humid environments. This property is especially beneficial for underground cable installations.

2.5. Enhanced Durability

Durability is also a significant advantage of cross linked polyethylene. This polymer possesses high tensile strength, which enables it to withstand mechanical stresses and external impacts.

It has good resistance to abrasion, cuts, and punctures, making it suitable for applications where durability is crucial. It remains stable and maintains its physical properties even under harsh conditions, ensuring long-lasting performance.

PEX pipes, for instance, can withstand high water pressure, temperature fluctuations, and harsh environmental conditions without cracking or corroding. This durability makes PEX a reliable choice for long-lasting plumbing systems, ensuring minimal maintenance and replacement costs.

2.6. Flexibility

XLPE is known for its flexibility, allowing for easy cable installation and routing even in confined spaces. Unlike rigid materials like copper or PVC, it can be easily molded into different shapes and forms, allowing for versatile applications. Additionally, the lightweight nature of cross linked polyethylene makes it easier to handle and transport, further enhancing its appeal in construction and plumbing projects.

XLPE can be molded into different shapes due to its high flexibility

2.7 Cost-effectiveness

PEX is a cost-effective alternative to traditional materials like copper and PVC. The lower material cost, combined with its ease of installation and reduced maintenance requirements, contributes to significant cost savings over the lifetime of a project. Additionally, PEX's longevity and durability minimize the need for repairs or replacements, further reducing expenses. As a result, builders, contractors, and homeowners are increasingly adopting polyethylene cross linked for various applications, recognizing its economic benefits.

3. Common uses of polyethylene cross linked

The unique properties of Cross-linked polyethylene make it highly versatile, leading to its widespread usage across various industries. Some common uses of polyethylene cross-linked include:

3.1 Plumbing and Heating Systems

One common application of XLPE is in plumbing systems. Cross linked polyethylene pipes are widely used for plumbing and heating systems in residential, commercial, and industrial buildings. They offer superior resistance to high temperatures and chemicals, ensuring reliable and safe water distribution, making them an excellent choice for carrying hot and cold water and radiant heating systems.

Cross linked polyethylene plays a vital role in constructing plumbing systems

3.2 Chemical Industry

Polyethylene cross linked is employed in chemical processing plants, refineries, and industrial settings due to its resistance to chemical corrosion. It is commonly used for aggressive chemicals transportation, chemical storage tanks, mining pipes, and oil and gas pipelines.

XLPE is widely used to make chemical storage tanks

3.3 Automotives

XLPE is also prevalent in the automotive sector. It is used for wire harnesses, fuel lines, and tubing due to its resistance to heat, chemicals, and mechanical stress. Its lightweight nature contributes to fuel efficiency and reduces vehicle weight.

XLPE is also important to the automotive industry

3.4 Electronics and telecommunications

PEX is extensively used for insulation in cables and wiring as insulation material.. Its excellent electrical insulation properties, thermal stability, and resistance to moisture and chemicals make it an ideal choice for transmitting electricity safely and efficiently.

PEX is extensively used for insulation in cables and wiring

3.5 Agriculture

Cross linked polyethylene pipes find use in agricultural applications for irrigation systems, water supply lines, and animal watering systems. They are resistant to weathering, UV radiation, and agricultural chemicals.

These are just a few examples of the many applications of polyethylene cross-linked. Its versatility, durability, and resistance to various environmental factors make it a popular choice in numerous industries.

A irrigation system made from cross linked polyethylene

4. Europlas - a world's leading plastic masterbatch manufacturer

Europlas is a globally recognized plastic masterbatch manufacturer. With a commitment to innovation, Europlas has established itself as a leader in the industry.

As a leading manufacturer, Europlas specializes in the production of masterbatches, which are additives used in plastics to impart desired properties such as color, UV resistance, flame retardancy, and more. These masterbatches are widely used across various industries, including packaging, automotives, electronics, construction, and consumer goods.

Europlas is one of the top leading plastic masterbatch manufacturers

Europlas is committed to delivering top-notch products that meet the specific needs and requirements of its customers. The company employs advanced manufacturing techniques and invests in cutting-edge research and development to ensure the highest level of quality and performance.

One of the key strengths of Europlas is its extensive range of masterbatch solutions. The company offers a diverse portfolio of plastic masterbatch, including:

- Color masterbatches: Have a comprehensive range of colors and shades to suit different product requirements and customer preferences. The masterbatches are formulated to ensure uniform dispersion of pigments throughout the plastic matrix, resulting in consistent and vibrant colors.

- Filler masterbatch: Is a cost-effective solution used to enhance the physical properties of plastic products. These masterbatches are composed of high-quality fillers, such as calcium carbonate or talc, dispersed in a polymer carrier.

- Engineering plastic compound: Is a specialized formulation combining different polymers, reinforcements and additives to enhance plastic properties. These compounds are tailored to meet the demanding requirements of engineering applications where standard plastics fall short.

- Bioplastic compound: Is a sustainable alternative to traditional plastics, derived from renewable resources such as starch, PLA, or PHA. These compounds offer comparable performance to conventional plastics and are degradable within 12 months, reducing the environmental footprint.

This broad range allows Europlas to cater to a wide range of applications and industry requirements.

Europlas’s color masterbatch

With its global presence, Europlas serves customers around the world, catering to both large-scale manufacturers and smaller businesses. The company's commitment to quality, innovation, and sustainability has earned it a reputation as a world leader in the plastic masterbatch industry.

Europlas is looking forward to assisting you and providing additional information. Please don't hesitate to contact us. Whether you have questions, need clarification, or require further details about our products or services, our team is here to help.

FAQs

Q: Is cross-linked polyethylene safe for plumbing applications?

A: Yes, crosslinked polyethylene is widely used in plumbing systems due to its safety and reliability. It offers resistance to high temperatures and chemicals, ensuring clean and safe water distribution.

Q: Can XLPE withstand extreme weather conditions?

A: Yes, XLPE is known for its durability and can withstand harsh environmental conditions, including extreme temperatures, UV exposure, and moisture.

Q: Are cross linked polyethylene cables more efficient than traditional cables?

A: Yes, XLPE cables offer improved electrical insulation properties and lower transmission losses, resulting in more efficient power transmission compared to traditional cables.

Q: Is cross linked polyethylene environmentally friendly?

A: XLPE is considered to be a relatively environmentally friendly material. It requires less energy to produce and has a longer lifespan. However, it is important to note that PEX is still a plastic material and should be disposed of properly and recycled whenever possible.