Engineering plastic compounds are one of the most advanced materials in the plastic industry today. With superior technical characteristics and excellent economic benefits, engineering plastic compounds have been chosen by many businesses. Read the following article to discover interesting information about this material!

Input materials account for over 50% of the production cost of finished plastic products, which is also a prerequisite for product quality and competitiveness. Therefore, mastering a source of high-quality, stable raw materials at a reasonable price is the key to successfully conquering the market. However, it is not an easy thing because the plastic processing process - even a simple product requires a variety of materials (base resin, pigments, additives, fillers, ...) with exact ratios. This inadvertently puts businesses in a difficult position when they have to work with many different suppliers at the same time as well as face great price risks. That is the reason why engineering plastic compounds were born.

1. Why engineering plastic compounds?

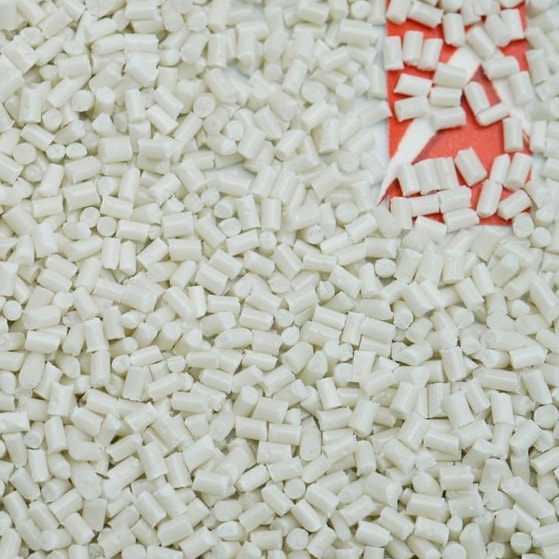

Engineering plastic (also known as engineering plastic compounds) is a combination of traditional plastic (PP, PC, ABS, ...) and reinforcing agents (fibers/glass beads, conductive carbon, flame retardants,...) and appropriate additives in certain proportions. The most outstanding feature of the compound resin is the ability to fully meet the technical requirements of the end product in a single specialized material. The advantages of products made from engineering plastics with traditional plastic materials are presented in detail in the table below:

|

Criteria

|

Products made from engineering plastic compounds

|

Products made from traditional plastics

|

|

Components

|

A single input material, carrying all the functions of the final product: hardness, strength, brightness, heat resistance, machining aids,...

|

Consisting of many constituent materials such as base resin, pigments, and additives (anti-UV, anti-aging, work aids,...), CaCO3 fillers help reduce production costs.

|

|

Manufacturing process

|

Time saving due to direct production without going through the process of mixing raw materials.

|

It takes a lot of time due to having to process input materials, and mix materials before extruding / extruding products.

|

|

Labor costs

|

Save labor costs by simplifying the production process.

|

Loss of labor cost due to more complex production process.

|

Comparison of technical and traditional plastic products

With the above advantages, engineering plastic compounds have been chosen by many businesses as an optimal raw material solution with modern production. Currently, there are many types of compounds developed to meet the increasingly diverse requirements of customers.

Engineering plastic compounds have been chosen by many businesses as optimal raw material solutions with modern production technology.

Engineering plastic compounds have been chosen by many businesses as optimal raw material solutions with modern production technology.2. Common applications of engineering plastic compounds

Some common types of engineering plastic compounds can be mentioned as PP compounds, ABS compounds, PC compounds, and PA compounds,... Along with the plastic base, reinforcing agents (glass beads/fibers, flame retardants, etc.) also help the finished product consolidate various technical characteristics and properties.

PP engineering plastic compounds

PP engineering plastic compounds are engineering plastic based on polypropylene (PP) resin mixed with different reinforcing agents (glass beads/fibers, conductive carbon black, flame retardant additives,...). With outstanding properties such as good elasticity, anti-deformation, electrical insulation, and high transparency, polypropylene is especially used in packaging, household appliance, and other industries that demand high aesthetics and durability over time.

|

Category

|

Features

|

Applications

|

|

PP glass fiber compounds

|

Increasing stiffness, reducing shrinkage, increasing flexibility, improving impact resistance and heat resistance of the end product.

|

Car interiors, motorcycles, electrical appliances, tables and chairs,...

|

|

PP glass bead compounds

|

Transparent shaping, good compression resistance and thermal stability.

|

Car interiors, interior decoration, home appliances,...

|

|

PP talc compounds

|

Increasing stiffness and flexural modulus, improving flexural strength, reducing shrinkage, good thermal conductivity,...

|

Production of details for cars, motorcycles,...

|

|

PP BaSO4 compounds

|

Good formability, reducing shrinkage and deformation with temperature

|

Manufacture of rice cooker covers, water filter equipment, vacuum cleaners, sanitary equipment,...

|

|

PP conductive compounds

|

Increased stability and conductivity

|

Electronic industry,...

|

|

PP flame retardant compounds

|

Increasing fire resistance and mechanical properties

|

Electrical and electronic industry...

|

PP plastic compounds are widely used in many manufacturing industries

ABS engineering plastic compounds

Based on ABS resin and reinforced components such as fiber/glass beads, and flame retardant additives,..., ABS engineering plastic compounds provide excellent rigidity, durability, electrical insulation, waterproofing, and anti-deformation. It’s great for finished products. The material is widely used in the electrical and electronic industries, the details require high thermal resistance and electrical insulation.

ABS engineering plastic compounds are widely used in the electrical and electronic industries, the details require high heat resistance and insulation ability.

ABS engineering plastic compounds are widely used in the electrical and electronic industries, the details require high heat resistance and insulation ability.PC engineering plastic compounds

PC engineering plastic compounds are a material based on PC resin and additives, reinforcing agents such as fibers/glass beads, anti-static additives, etc., in accordance with the characteristics of the end products. The material helps to strengthen the surface hardness, impact resistance, and anti-static for products, often widely used in the production of computer components, electronics, office equipment, cameras, etc...

The material reinforces the surface hardness, impact resistance, and anti-static properties of finished products.

The material reinforces the surface hardness, impact resistance, and anti-static properties of finished products.PA66 engineering plastic compounds

With a combination of PA resin and reinforcing components such as beads/fiberglass, PA66 compound is an important material in the production of gears, bearings, household electrical components, office equipment, automobiles, and motorcycles,... These are details that require extremely high precision and wear resistance.

PA6 engineering plastic compounds

PA6 engineering plastic compounds are a mixture of PA resin reinforced with beads/glass fibers. PA6 engineering plastic has good chemical resistance, electrical insulation as well as damping and noise reduction in machine parts when working. The material is used in the production of coils, packaging, bottle caps, car dashboards,...

3. EuroPlas engineering plastic compounds - the optimal solution for plastic manufacturers

EuroPlas engineering plastic compounds is the most advanced material manufactured and distributed by European Plastic Company. With more than 15 years of experience in the industry, EuP understands the difficulties of businesses when looking for a stable and quality source of raw materials. EuroPlas technical plastic beads are born as a crystallization of our decades of knowledge, technology, and valuable experiences.

Products are made from selected, high-quality raw materials at reasonable prices, and specially designed according to the requirements of each customer. EuroPlas engineering plastic compound fully converges features in a single material, thereby simplifying the production process as well as saving labor costs and increasing productivity for businesses.

EuroPlas provide a full-function-in-one-material solution for end-products

Currently, EuP is providing a full range of the most popular compound codes on the market such as PP compound, PC compound, ABS compound, PA66/PA6 compound, Bio compound,...and constantly researching and improving to meet the ever-changing requirements and diverse needs of customers.

For more detailed product information and consultation, please contact us!

EuroPlas provide a full-function-in-one-material solution for end-products

Currently, EuP is providing a full range of the most popular compound codes on the market such as PP compound, PC compound, ABS compound, PA66/PA6 compound, Bio compound,...and constantly researching and improving to meet the ever-changing requirements and diverse needs of customers.

For more detailed product information and consultation, please contact us!