In the realm of electronics and sensitive equipment, the battle against the unseen but potentially damaging force of static electricity is a critical one. ESD, or Electrostatic Discharge, poses a significant threat to the integrity and functionality of electronic components. To combat this, a class of materials known as ESD materials has emerged, playing a pivotal role in controlling and neutralizing static electricity. But what exactly are ESD materials, and how do they safeguard our electronic devices? Let's delve into the realm of ESD materials to uncover their significance and functionalities.

1. What is static electricity?

The phenomenon of static electricity is often seen in practice

Have you ever taken off your shirt and heard a cracking sound coming from it? Or when you try rubbing a plastic ruler on clothes, or a plush cloth and then put it on your hair and see the hair stand up? That is the phenomenon of static electricity.

Static electricity arises from an imbalance of electrons that can leap between surfaces or materials upon contact. This phenomenon occurs particularly when one material is highly insulative, impeding the flow of electrons. The transferred electrons accumulate on the insulative surface until neutralized, either through grounding or interaction with a material of opposite polarity.

This phenomenon does not affect our daily lives much, however, in industry, it has significant potential harm. In environments such as laboratories, the buildup of electrons on insulative materials poses risks, potentially leading to damage or loss of magnetic data when neutralized by sensitive electronics.

Furthermore, the accumulation of electrostatic energy can pose hazards, triggering sparks that may ignite flammable liquids or materials. To mitigate these risks, the careful prevention or control of static electricity is essential, and this is precisely the purpose served by ESD materials.

2. What are electrostatic discharge materials?

Electrostatic discharge materials, often called ESD materials, are special types of plastics crafted to lower the risk of static electricity. Their main job is to keep electrostatic sensitive devices (ESD) safe from harm and also to avoid any accidental sparks that could ignite flammable liquids or gasses.

These materials act as protectors, making sure that the buildup of static electricity doesn't cause damage to sensitive devices or create any unsafe situations with things that easily catch fire. In short, they're like the guardians against unwanted sparks and potential damage in environments where static electricity is a concern.

3. Types of ESD materials

3.1. Anti-static materials

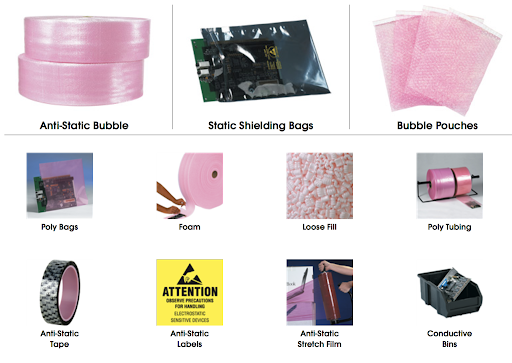

Antistatic packaging materials

Anti-static materials play a crucial role in mitigating the effects of triboelectric charging, a phenomenon that occurs when two materials come into contact and transfer electrons. Unlike insulative materials that hinder the flow of electrons, anti-static materials are specifically engineered to impede the creation and accumulation of static charges on the surface of an object.

This type of material ensures that electrons do not accumulate on the surface of the item. Using anti-static materials is a very important preventative measure, especially in environments with sensitive electronic components.

Moreover, the versatility of anti-static materials is noteworthy, as they can be formulated with additional conductive or dissipative qualities. This adaptability allows these materials to address various levels of static electricity, providing comprehensive protection against electrostatic discharge. Whether incorporated into packaging, work surfaces, or personal protective equipment, anti-static materials contribute significantly to maintaining the integrity and functionality of electronic devices.

Read more: Antistatic Agents Overview (2022)

3.2. Conductive materials

Conductive materials are like speedy highways for electrons—they let them move quickly. These materials either let electric energy escape into the ground or pass the charge to something else conductive.

But here's the catch: while conductive materials are good at getting rid of electric charge by connecting to the ground, they're not always the best choice for ESD tables. This is because they might accidentally pass the charge to nearby things, like sensitive equipment or materials that can get harmed.

So, when it comes to tables or places where static electricity needs careful control, we often prefer materials that are a bit different—ones that can handle static charges more safely without passing them around too much.

3.3. Electrostatic-dissipative materials

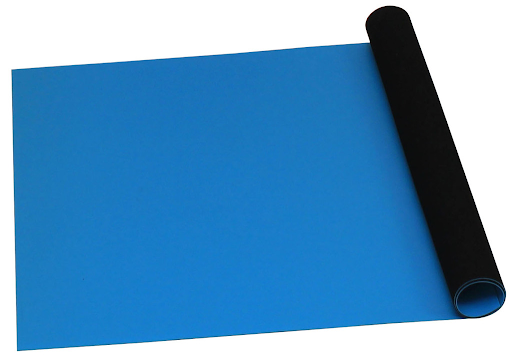

The product is made from electrostatic-dissipative materials

Electrostatic-dissipative materials are like superheroes in preventing shocks in places with lots of electronics. They're made by mixing special plastics and metals. The cool thing about them is that they let electric charges move slowly, like a calm river, and make sure the energy doesn't get too strong to cause any problems.

These materials are perfect for places with electronics because they can safely get rid of static energy without risking any harm to sensitive stuff. If you touch them or if something delicate hangs out nearby, they won't pass on the electric charge. It's like they make a safe space where static electricity can quietly disappear without causing any issues.

And here's the bonus: these materials are also called 'anti-static.' That means they're good at stopping static energy from building up in the first place. Therefore, in the electronics industry, electrostatic dissipation materials are always the best choice to ensure maximum safety.

4. Conclusion

In conclusion, ESD materials are useful for protecting electronic devices from the threat of static electricity, especially in the electronics industry. As technology continues to advance, the need for reliable ESD solutions is becoming more widespread and important. Whether it is electrical conductive materials, static dissipative materials, or anti-static plastics, they all contribute to creating safer and more durable electronic products.

5. About EuroPlas

Manufacturers often add antistatic additives to plastics to minimize the buildup and transfer of static charge, especially in applications involving sensitive electronics. Antistatic plastics are often used in the production of packaging materials, and electronic components, or in environments where static electricity control is needed to protect devices such as computers, cell phones, or other electronic components.

At EuroPlas, we offer you a wide selection of antistatic additives, which can reduce the possibility of static electricity on plastic surfaces, making the production process safer and more efficient. This type of additive is used to dissipate or promote the breakdown of static electricity, as well as improve machinability, lubrication, and mold release.

In addition, we also produce and distribute ABS antistatic compounds. Thanks to the combination of ABS plastic granules and antistatic plastic additives, EuroPlas creates a flexible plastic that is flexible, easy to process, heat resistant, impact resistant, and dissipates static electricity. The ABS-antistatic compound is commonly used in applications where static electricity can be detrimental to the product or the user, such as electronic components pallets, mobile chargers, power sockets, and earphones.

ABS Antistatic compound at EuroPlas

EuroPlas is proud to offer unique plastic material solutions, helping customers' factories optimize production costs and improve businesses' competitiveness in the market. Up to now, thousands of factories in more than 90 countries around the world have chosen EuroPlas products.

Behind a pioneering EuP with optimal material solutions is a team of leading experts and thousands of staff and technicians who work day and night to bring the best quality products to customers. We provide a diverse range of plastic products, meeting many different requirements of the world plastic market.

Besides the above products, we also have other outstanding plastic products, including:

- Bioplastic compound: The green raw material solution that helps finished products biodegrade within 12 months

- Color masterbatch: This is applied to industrial activities such as film blowing, injection molding, extrusion blow, and other applications. We also provide specialized color masterbatch products with diverse effects according to the requirements of the finished product.

- Plastic additives: EuroPlas provides many types of plastic additives, including deodorizing additives, desiccant additives, flame retardant additives, anti-fog additives, anti-aging additives, processing aids, and anti-ultraviolet additives, and additives to increase clarity and brightness...

- Engineering plastic compound: EuroPlas technical plastic compound is the optimal solution with flexibility, high quality, and all functions in just one material. EuroPlas provides engineering plastics including PBT GF-FR compound, blend PA6, PA66, PC fireproof compound, and ABS fiberglass compound...

- Filler masterbatch: EuroPlas has More than 16 years of manufacturing and exporting filler masterbatch to thousands of businesses in Asia, the Middle East, Africa, and Europe... and is currently the number 1 filler masterbatch manufacturer in the world.

- Bio filler: BiOMates brand Biofiller is a suitable choice for producing environmentally friendly products such as biological packaging, and extrusion of disposable plastic items.

Visit our blog to learn more useful information. If you are in need of detailed advice about EuroPlas products, do not hesitate to contact us. EuroPlas is always ready to support you.