In increasingly modern life, fossil fuels-based plastics pose major environmental threats, such as pollution, and are non-degradable. Because of this, there is an increasing demand for bioplastics which are potential and sustainable alternatives to deal with plastic litter and conserve ecosystems. Among these, aliphatic polyester is considered a worthwhile choice, due to many outstanding properties compared to others. This article will show the definition, and the differences of bio polyester, decode the aliphatic polyester’s structure, and find out some applications of aliphatic polyester across industries.

1. What is aliphatic polyester?

Aliphatic polyesters are derived from naturally occurring compounds, such as lactide (LA), glycolide (GL), and ε-caprolactone (CL). An aliphatic polyester is a long-chain polymer that consists of repeating ester groups. Bacteria and other living things can break it down, therefore, that polyester is regarded as a biodegradable molecule.

These polymers feature long chains with repeating ester groups, which are key to their biodegradable and biocompatible nature. Compared to other polyesters, aliphatic polyesters have simple structure, excellent biodegradability, and lower mechanical and thermal properties.

Read more: How different types of bioplastics are produced?

2. Decoding aliphatic polyester’s structure

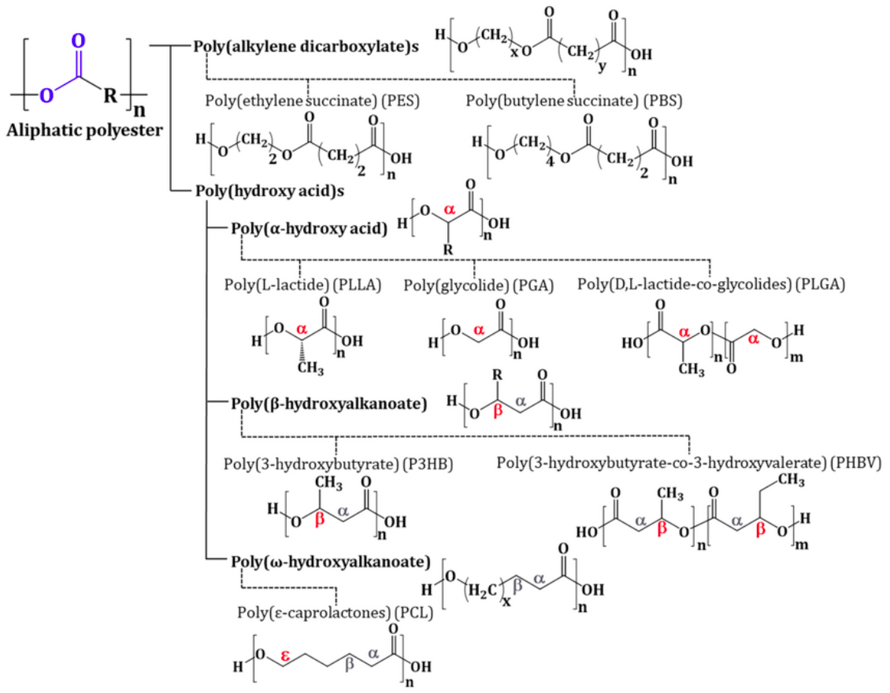

By using other compounds, we can create diverse types of aliphatic polyester, hence they have different structures. To learn about aliphatic polyester’s structure, we have:

Classification and structure of aliphatic polyester

2.1. Poly(alkylene dicarboxylate)s

Poly(alkylene dicarboxylates) are created by reacting a dicarboxylic acid or its alkyl ester with an alkanediol, using a titanium-containing chelate compound as a catalyst.

This chelate compound can be formed through the reaction of a tetraalkyl titanate with a carboxylic acid derivative such as methyl salicylate, malic acid, glycine, or dibutyl tartrate.

This polymerization technique helps reduce ester-carbonate interchange in mixtures of poly(alkylene dicarboxylates) with aromatic polycarbonates, and several of these chelates are new compounds.

There are two types of poly(alkylene dicarboxylate)s, including:

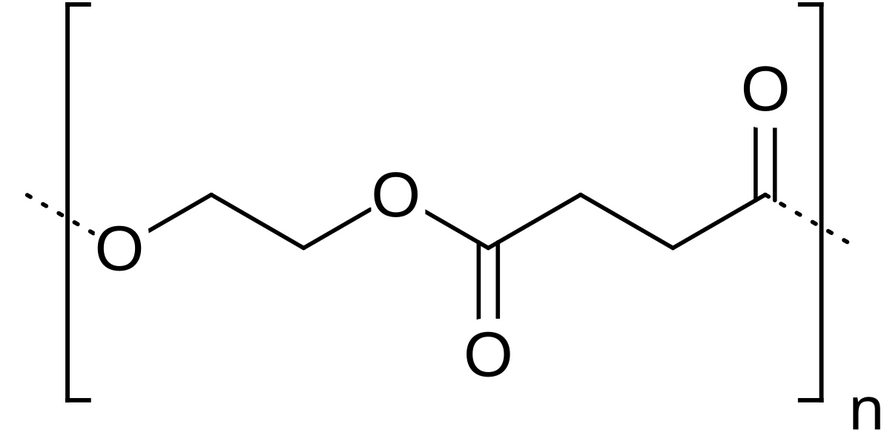

- Poly(ethylene succinate) (PES) is an aliphatic synthetic polyester with a melting point from 103 - 106°C. It is synthesized from dicarboxylic acids; either by ring-opening polymerization of succinic anhydride with ethylene oxide or by polycondensation of succinic acid and ethylene glycol.

Chemical structure of poly(ethylene succinate) (PES)

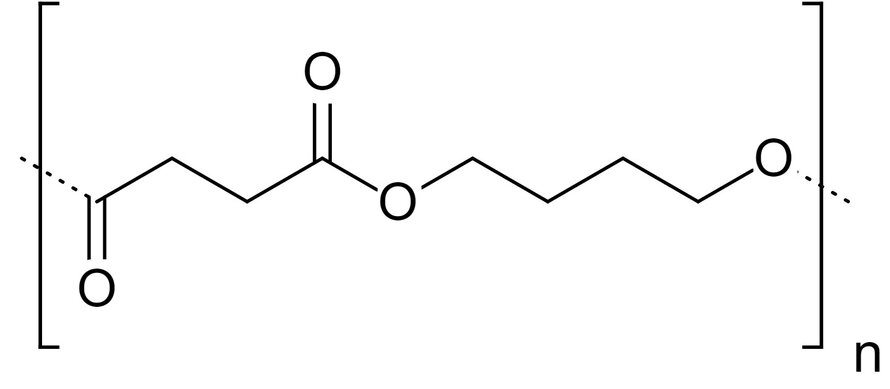

- Polybutylene succinate (PBS) being a versatile semi-crystalline polymer has the repeating unit represented by the formula –[O–(CH2)m–O–CO–(CH2)n–CO]N. The chemical structure of PBS contains an ester group, which will degrade into low molecular weight polymers when exposed to water. As the temperature increases, the degradation rate of PBS also rises.

Chemical structure of a unit in PBS

Read more: What is polybutylene succinate? Structure, biodegradability, and applications

2.2. Poly(hydroxy acid)s

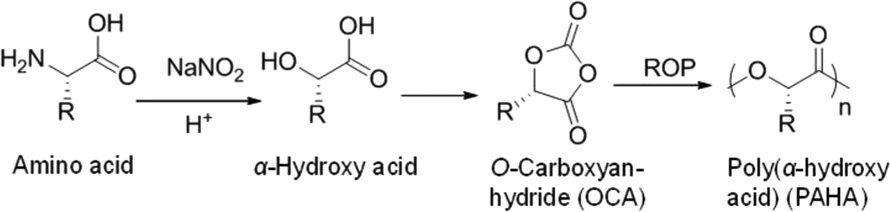

Poly(hydroxy acids) are polyesters synthesized from hydroxy acids, which are extracted from renewable resources and biowaste. There are some types of outstanding poly(hydroxy acids) such as:

The structure of poly(α-hydroxy acid)

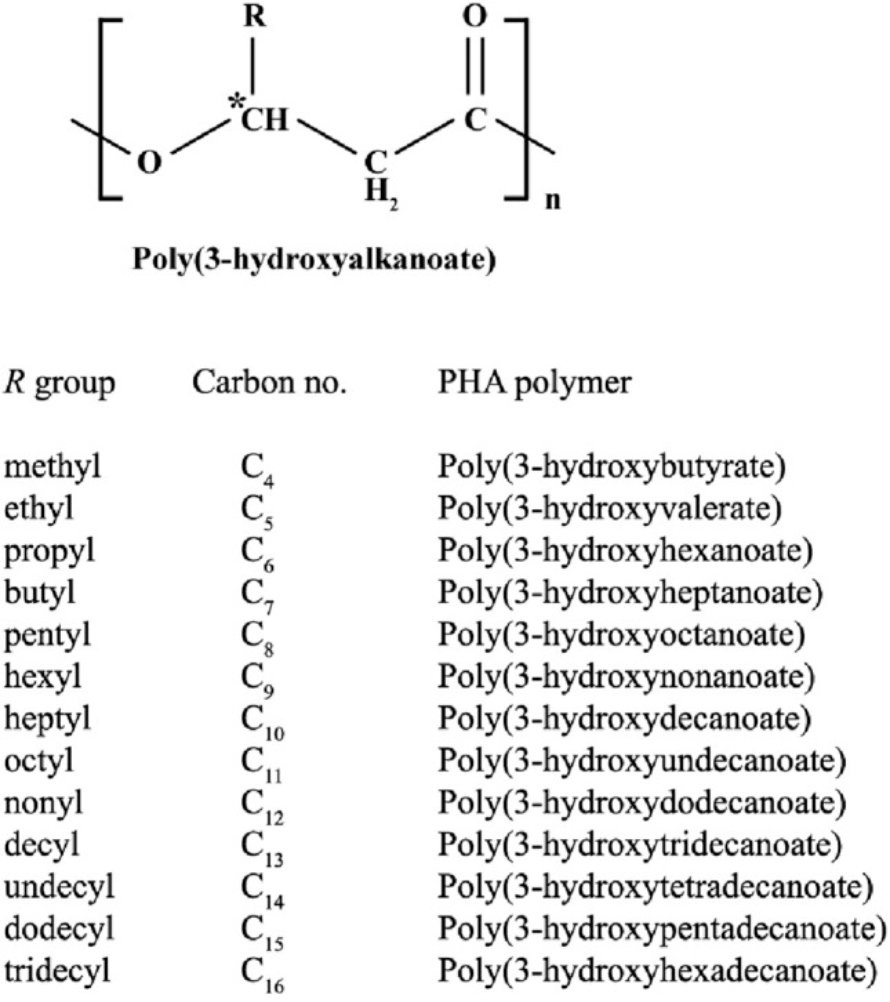

- Poly(β-hydroxyalkanoate) (PHAs) is a linear polyester that contains 3-hydroxy fatty acid monomers. Hydroxyl group from one monomer forms an ester bond with the carboxyl group of another monomer unit. The R group in the structure represents the alkyl group. If the R group is methyl (CH3), the polymer is named poly(3-hydroxybutyrate) as it will contain four carbons in the monomer unit, likewise if R is C3H7, it is called poly(3-hydroxyhexanoate).

Structure and types of poly(β-hydroxyalkanoate)

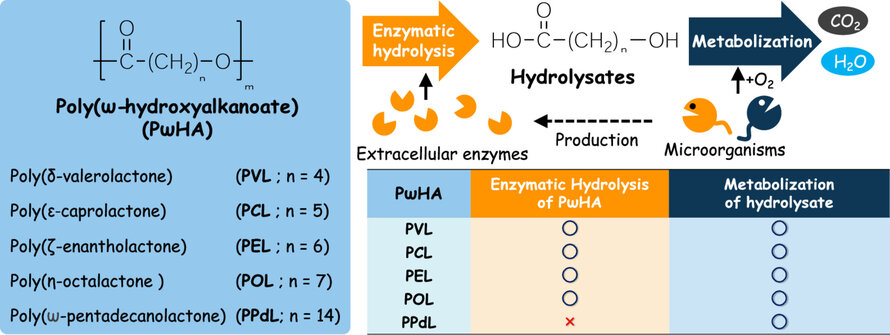

- Poly(ω-hydroxyalkanoate) (PωHA) is created by ring-opening polymerization of the corresponding lactones, δ-valerolactone (VL), ε-caprolactone (CL), ζ-enantholactone (EL), η-octalactone (OL), and ω-pentadecanolactone. There are some of that polyesters such as poly(δ-valerolactone) (PVL; n = 4), PCL (n = 5), poly(ζ-enantholactone) (PEL; n = 6), poly(η-octalactone) (POL; n = 7), and poly(ω-pentadecanolactone) (PPdL) (n = 14).

Structure and some types of poly(ω-hydroxyalkanoate) (PωHA)

3. Applications of aliphatic polyester across industries

Aliphatic polyesters, known for their biodegradability and versatility, find a wide range of applications in various industries, such as:

- Tissue engineering: Aliphatic polyesters can support tissue engineering efforts and develop scaffolds, for example, PLA can be combined with other polymers to produce new biomaterials with suitable physicochemical properties for tissue engineering applications.

- Develop drug delivery systems: Some aliphatic sources of polyesters also have excellent biodegradability and biocompatibility, making them effective for certain medical applications. For instance, PLA has been widely studied for use in medical applications because of its bioresorbable and biocompatible properties in the human body. PCL has been approved by the Food and Drug Administration (FDA) and has undergone considerable research to be used in drug delivery systems.

- Create medical equipment: Scientists indicated that aliphatic polyester such as PCL, PLA, PBS, PHA, PGA, etc can be used for implant materials, sutures, etc.

4. Conclusion

In summary, aliphatic polyesters, thanks to their unique chemical structure, can be biodegradable and become key and potential materials in both current and future applications. By delving into research on aliphatic polyester properties and improving the production process, we can move further breakthroughs and bring perfect solutions for ecosystems and industries.

5. About EuroPlas

EuroPlas is renowned as the world's No. 1 filler masterbatch manufacturer. Besides, we acknowledge that biomaterials will play an important role in various industries because of sustainable development. Enterprises, society, and governments must cooperate to solve plastic garbage problems by improving alternative solutions.

Therefore, EuroPlas not only provides diverse types of plastics such as engineering plastic compounds, plastic additives, etc, but also brings the global market some green material solutions, including bioplastic compounds and bio filler. Our products ensure to help customer’s factories optimize production costs and improve competitiveness in the international market.

EuP owns several modern equipments, such as extruders, blown film machines, and injection molding machines, ... along with a system of standard testing machines, such as plastic thermal deformation testing machines, impact testing machines, tensile strength testing machines, etc, thus ensuring the highest-quality products to customers.

Let us know if you are looking for suitable materials for your projects. We will support the best for your needs and enhance your plastic competitiveness with optimal material solutions.