PP BaSO4 Compound is an extremely necessary component in modern industry. Products made from this material are always a symbol of excellent performance and durability over time.

PP BaSO4 compound is widely used in many different areas of life today. With outstanding advantages and uses, this material contributes to the production of high-quality products and promotes a green environment. Learning about PP BaSO4 compound is a simple way to contribute to upgrading your production process in a positive direction today!

1. What is PP BaSO4 Compound?

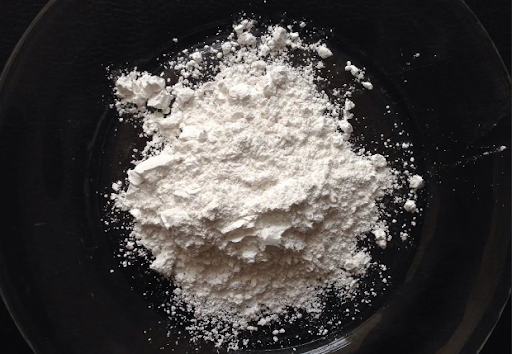

PP BaSO4 compound is a combination of Polypropylene and Barium Sulfate

PP BaSO4 compound has the full name Polypropylene Barium Sulfate. This is a very good additive in the field of plastics and coatings. This compound is a combination of Polypropylene and Barium Sulfate after improving some properties of the original compound such as opacity, brightness and UV resistance.

In fact, PP BaSO4 compound is very popular in many areas of life today. The application of PP BaSO4 compound will provide a solution to increase product durability and performance by improving not only the mechanical properties of the material but also its resistance to various physical factors from the environment. Moreover, it helps to significantly reduce production costs and can act as an excellent filler without reducing the quality of the product.

Moreover, PP BaSO4 compound is also environmentally friendly, affirming the sustainable potential of the material in the future. They are one of the elements in the green transformation of modern industries.

PP BaSO4 compound offers many outstanding benefits that improve the diverse functions of the product and are environmentally friendly. Some of the following important benefits will reveal why companies value PP BaSO4 compound in many different fields.

Read more: Applications of PP BaSO4 composites in pipes and fittings

2. Benefits of Using PP BaSO4 Compound

2.1. Improved mechanical strength

PP BaSO4 compound is an additive that increases the mechanical properties of plastics. Therefore, they bring higher tensile strength and impact resistance to the application. Therefore, PP BaSO4 compound is considered as a factor that helps products to be more durable when operating in harsh environments such as the automotive and construction industries.

2.2. Improved opacity and brightness

The addition of Barium Sulfate is a technique that helps increase the opacity and brightness of products. This high property especially plays a key role in packaging and coatings and some applications that emphasize appearance and light blocking ability.

BaSO4 is added to address the limitations of PP such as shrinkage, limited heat resistance, chemical resistance, and impact resistance

2.3. Cost effective

Substituting PP BaSO4 compound as a filler is a very versatile way to reduce manufacturing costs. It is a less expensive additive but does not affect the quality of the product in any way. Therefore, this helps manufacturing companies to gain higher profit margins while still improving the performance level of the product.

2.4. UV protection

PP BaSO4 compound is a polymer that provides strong UV protection to the product. Due to this property, the material will not degrade due to exposure to sunlight. This is a huge benefit that prolongs the life of the material and reduces maintenance costs for outdoor applications where they are used.

2.5. Environmentally friendly

Barium sulfate is an environmentally friendly filler. It is considered to be completely non-toxic and helps improve the overall sustainability of the items. Specifically, companies that combine PP BaSO4 compound can produce environmentally friendly materials that meet both green standards and manufacturing standards.

2.6. Versatility in application

PP BaSO4 compound not only shows good versatility but is also applied in many different types of industries such as automobiles, construction and consumer goods. Products manufactured from PP BaSO4 compound all show many outstanding properties suitable for each different application. The reason is that their properties have been improved compared to the basic functional level.

3. How to Choose the Right PP BaSO4 Compound

Choosing the right PP BaSO4 compound is the most important factor in ensuring excellent quality and achieving the desired results in many different fields. Here are some key approaches to choosing the most suitable PP BaSO4 compound for your needs.

A reputable supplier can provide high purity compounds, limiting impurities to the lowest possible level

3.1. Evaluate the application requirements

When choosing the most suitable PP BaSO4 compound for your application, it is first and foremost important to evaluate the specific requirements of the final product. Factors such as mechanical strength, opacity and thermal stability cannot be ignored. In addition, differences in quality between different PP BaSO4 compounds can be due to different chemical compositions. Therefore, understanding the application requirements is very important to get the best performance for the product.

3.2. Evaluate the purity and quality

The quality of the Barium Sulfate used in the PP BaSO4 compound is one of the biggest factors affecting the performance of the product. Some suggestions to consider include finding a reputable supplier who will provide you with high purity compounds while maintaining the same particle size and limiting impurities to the lowest possible level. Checking the supplier's certification and conducting material quality testing can be considered as a guarantee of product quality according to the standards of the manufacturing industry. This is one of the factors considered extremely essential to improve product quality in the most effective and safe way.

3.3. Consider the environmental impact

Ecological concerns have become the focus of attention as the question of sustainable development becomes increasingly important. It is advisable to choose products that contain the lowest level of toxicity during the manufacturing process. It would be great if the supplier provides a detailed report on the environmental certifications of the compound. This can be a decisive criterion for longevity and competitiveness for environmentally conscious businesses.

4. Applications of PP BaSO4 Compound

One of the reasons why PP BaSO4 compound is highly appreciated is that it greatly improves the performance and quality of the product. Here are some of the main applications of PP BaSO4 compound that demonstrate its effectiveness and importance in modern manufacturing.

Automotive components: PP BaSO4 compound is widely used in the automotive industry for various reasons. One of them is that it helps parts such as bumpers, dashboards and interior trim become more durable and stronger during the manufacturing process. Moreover, PP BaSO4 compound is superior to other materials in terms of mechanical properties and UV resistance, making it the best choice for parts exposed to rain, frost or high temperatures. It can be seen that they limit the swelling or cracking and help prolong the life of these parts when operating for a long time.

PP BaSO4 compound is widely used in the automotive industry for various reasons

Construction materials: In the construction field, PP BaSO4 compound is used to make pipes, profiles and panels, etc. This compound enhances the mechanical properties (weakness, elongation, compressive strength, hardness), impact resistance and durability of the product. In addition, the opacity and brightness of the building material are also enhanced due to the inherent properties of Barium Sulfate.

Equipment coatings: PP BaSO4 compound is mainly used in equipment coatings to improve the opacity level. The reason is that they have good light diffusion and scattering ability through reflection or transmission (or translucency). PP BaSO4 compound is an excellent choice for effective coatings for applications that help create a surface with high aesthetics. For example, automotive coatings or industrial coatings made from PP BaSO4 compound will have bright colors and durable UV resistance properties against light. In this way, the finish will be more durable under sunlight and will deteriorate faster.

PP BaSO4 compound is a non-toxic material, ensuring safety for consumers of all ages

Consumer goods: The wide range of applications of PP BaSO4 compound in many items such as bags, household items and toys is mainly due to the lightweight and affordable nature of the product. Therefore, it is the first choice for manufacturers who want to achieve better product quality and save some costs at the same time. In particular, this is a non-toxic material, ensuring safety for consumers of all ages.

Insulating devices: They are popular materials in the electrical industry, often used to produce cables, connectors and protective shields. Products made from PP BaSO4 compound possess excellent properties such as good insulation, good dielectric strength, resistance to temperature and strong chemical effects. PP BaSO4 makes electrical systems safer and more efficient.

5. Conclusion

In conclusion, PP BaSO4 compound is one of the ideal choices for a modern production process. Their position is increasingly affirmed through highlighting their benefits, applications, and excellent properties. The selection of a PP BaSO4 compound should also be considered through a few core factors to ensure the efficiency of the product. In the context of industries constantly upgrading, PP BaSO4 compound will still be a symbol of sustainable materials not only for quality but also for an environmentally friendly production culture.

6. Introducing PP BaSO4 Compound from EuroPlas

EuroPlas's formulation also brightens the material and reduces manufacturing costs

EuroPlas is proud to be a leading global plastic manufacturer and supplier. We have developed one of the best PP BaSO4 grades available on the market and we are constantly working to improve our products.

EuroPlas PP BaSO4 compound is a blend of Barium Sulfate(BaSO4) and Polypropylene (PP), along with a number of other additives to create a lightweight, low-density material with many significant benefits. BaSO4 is added to address the limitations of PP such as shrinkage, limited heat resistance, chemical resistance, and impact resistance. This results in a finished material that is excellent in performance and quality.

EuroPlas's formulation also brightens the material and reduces manufacturing costs. Contact EuroPlas today! With EuroPlas's extensive experience in the industry, we absolutely guarantee the supply of high quality plastic materials that are designed to best suit our customers' requirements.