In the rapidly advancing world of electronic devices, ensuring safety and mitigating potential fire hazards is paramount. Flame retardant materials play a pivotal role in this quest for safety, and among them, Flame Retardant Polycarbonate (PC) stands out as a top choice. This robust and fire-resistant material not only enhances the reliability of electronic devices but also contributes significantly to safeguarding users and their surroundings. Let's delve into the key attributes that make Flame Retardant PC optimal for ensuring the electronic device safety that you are using.

1. What are flame retardant plastics?

The category of flame retardant resins primarily includes flame retardant high-impact polystyrene resin, flame retardant polypropylene resin, flame retardant ABS resin, Polyoxymethylene, Polyamide – Polyamit and more. These products are further classified into different flame retardant specifications based on their flame resistance levels, such as UL94 V0, UL94 V1, UL94 V2, and UL94 HB.

Read more: 5 common fire resistant plastics and how to enhance plastic fire resistance

Flame retardant plastics, in comparison to standard plastics, offer significant risk reduction in the occurrence of fire-related incidents, such as short circuits, overloads, water immersion, and other scenarios.

2. How to make flame retardant plastics?

This type of plastic is created by adding flame retardant additives to regular plastic, these additives are called flame retardants.

Flame retardants, vital components in the realm of fire safety, are a diverse array of chemicals strategically applied to materials to either prevent burning or significantly slow down the spread of fire.

In essence, flame retardants, often denoted as FRs, serve as integral additives specifically designed to inhibit or retard the ignition and burning of plastic. The rationale behind their incorporation lies in the quest to engineer polymers with thermal stability, minimizing the likelihood of decomposing into combustible gasses when exposed to heat stress.

The effectiveness of flame retardants (FRs) in enhancing fire safety is diverse, and they can be categorized based on their chemical compositions. Here's an overview of flame retardant additives classified by chemical category:

- Halogenated additives: Among the various chemical categories, halogenated additives are widely employed, with brominated FRs being the most prevalent. Halogenated FRs operate in the gas phase above the burning polymer surface, chemically disrupting the flame propagation mechanism. By releasing halogen radicals, they interfere with the combustion process, effectively suppressing the spread of flames.

- Intumescent additives: Another significant category is intumescent additives, featuring phosphorus-based FRs. These additives react with the polymer substrate during combustion, producing a char layer. This char layer acts as a robust barrier, effectively separating the heat source, oxygen, and the fuel generated from the polymer's pyrolysis. The efficiency of flame retardancy in this category is closely tied to the inherent charring tendency of the polymer.

- Spumific additives: These additives decompose at the combustion temperature of the polymer, generating inert gasses such as CO2 and H2O. The released gasses dilute the combustion gasses, creating a hindrance to the burning process. This mechanism effectively curtails the propagation of flames.

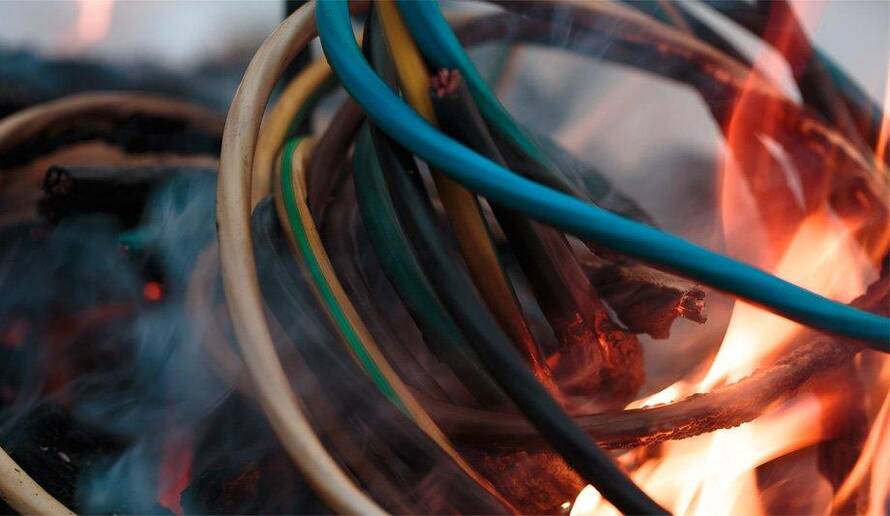

3. The importance of flame retardant plastics

Flame retardant plastics play an important role in fire risk mitigation

In the dynamic landscape of modern industries, where polymers are extensively utilized, ensuring fire safety is paramount. Polymers, organic in nature, possess the potential to fuel fires, presenting challenges across sectors like electrical, electronic, transportation, and construction. The diffusion of synthetic polymers has elevated both the likelihood of fire occurrence and the consequential risks to human safety and infrastructure.

To address these challenges and comply with rigorous safety standards, the usage of flame retardant plastics has become indispensable. Specifically, the important role of fireproof plastic in industry and life can be mentioned as follows:

- Fire risk mitigation: Flame retardant plastics are crucial in reducing the probability of fire occurrence, especially in industries heavily reliant on polymers. In sectors like electrical, electronic, transportation, and construction, flame retardants play a pivotal role in safeguarding occupants and structures from the potential consequences of fires.

- Fire extinction: The primary function of these additives is to slow down polymer combustion and degradation, contributing significantly to the extinguishing of fires.

- Smoke reduction: Flame retardants effectively reduce smoke emissions, minimizing the health hazards associated with fire incidents.

- Protect electrical and electronic equipment: By averting the dripping of burning materials, flame retardants add an additional layer of safety, particularly in environments where rapid fire spread is a concern.

- Legal compliance: Meeting stringent legal requirements necessitates the incorporation of flame retardants into polymer formulations to ensure adherence to safety standards.

- Increased escape time: Flame retardant plastics extend the time available for individuals to safely evacuate fire-affected areas, supporting overall emergency response efforts.

4. What is Flame Retardant PC? Outstanding features

Polycarbonate (PC) stands out as a remarkable thermoplastic material, characterized by its colorless and transparent nature, making it an ideal choice for various applications. As a widely used thermoplastic, PC boasts exceptional attributes such as lightness, durability, impact resistance, and high-temperature tolerance. Its versatility extends to excellent optical clarity and outstanding electrical insulation properties.

Flame Retardant PC takes the inherent qualities of PC to the next level by incorporating flame retardancy. By combining with fire-retardant additives, we get a new type of PC plastic, which still retains its original excellent properties and has additional fire resistance.

PC, being inherently flame-resistant, catalyzes carbon formation during combustion, ensuring self-extinguishing properties. This makes PC, after combining with fire-retardant additives, a sought-after material for automotive and electronic components.

Flame Retardant PC possesses excellent electrical insulation, high heat resistance, and dimensional stability. It falls under the category of self-extinguishing engineering plastics, meeting stringent safety standards. Widely utilized in the production of plastic parts for automobiles and electronic devices, manufacturers often aim for a flame retardant grade of UL94V-0, ensuring top-tier fire safety.

Some outstanding features of Flame Retardant PC:

- Fire resistant, self-extinguishing, and does not create smoke.

- Achieve quite high fire-resistance ratings.

- Good flame retardant performance to ensure no spontaneous fire damage during high energy usage

- High transparency provides excellent product aesthetics

5. Why should Flame Retardant PC for electronic devices?

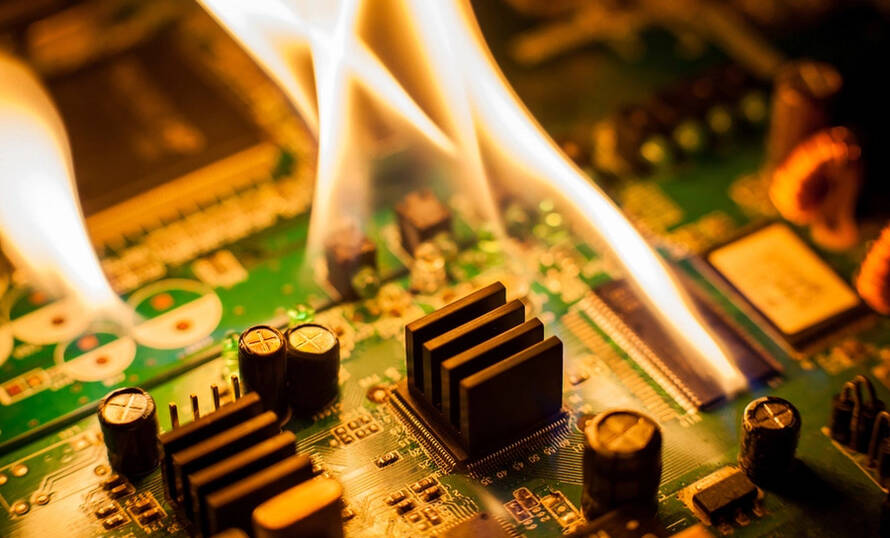

The average household owns more than 20 electronic products, an indispensable part of daily life. Flame Retardant PC has emerged as an important component ensuring the safety of these devices. This specialized polymer not only reduces the risk of ignition but also limits the possibility of fire spreading.

Why is Flame Retardant PC cam optimal for electronic device safety?

Many studies have emphasized the importance of fire-resistant PC in improving the safety of consumer products. This type of plastic is often used to manufacture the casings of electronic products and has been shown to prevent short circuits and prevent overheating, thereby reducing the risk of fire and explosion.

Additionally, by incorporating Flame Retardant PC in the production of electronic devices, we can maintain the longevity and functionality of these products.

The PC Flame Retardant compound manufactured by EuroPlas combines polycarbonate plastic with a flame retardant to meet precise safety standards. EuroPlas supplies a PC-FR compound made of PC resin mixed with halogen flame retardant. Tailored to cater to diverse needs, this compound comes in a range of UL94 standard fireproof levels, including 5VA, 5VB, V0, V1, and V2.

Why choose EuroPlas PC Flame Retardant compound?

- Versatility: Our compound serves as an all-in-one material, seamlessly integrating multiple functions into a single solution.

- Direct processing: EuroPlas PC-FR compound allows for direct processing without the need for additional materials, streamlining your manufacturing process.

- Tailor-made PC Flame Retardant compound: Created to meet specific end product requirements, our compounds can be tailored to each customer's individual needs, to suit your plastic product.

- Performance enhancement: EuroPlas PC-FR compound goes beyond safety, increasing the stiffness, thermal ability, and impact strength of your end-products.

The PC Flame Retardant compound manufactured by EuroPlas

EuroPlas specializes in providing high-quality engineering plastic compounds, and our PC-FR compound is ideal for various applications, such as:

- Mobile chargers: Ensure safety in electronic devices crucial for daily life.

- Keyboards: Enhance safety features in electronic peripherals.

- Power sockets: Elevate the safety standards of electrical components.

- Electronic components: Safeguard critical elements in electronic manufacturing.

- Earphones: Prioritize safety in personal audio devices.

EuroPlas is a leading manufacturer in the plastic industry, not only providing plastic products, plastic additives, filler masterbatch, and color masterbatch... but also committed to safety and reliability. We believe that EuroPlas PC flame retardant compounds are the optimal manufacturing solution for electronic and electrical equipment, ensuring safety without compromising performance.

7. Conclusion

In conclusion, the Flame Retardant PC emerges as not just a technological advancement but a protective material for our safety in the digital age. As we continue to innovate and integrate electronics into every aspect of our lives, the optimal safety provided by Flame Retardant PC becomes an indispensable shield against potential fire hazards. Let’s embrace the future of electronic device safety – embrace Flame Retardant PC.

Contact us immediately if you are looking for a quality, reputable supplier of PC fire retardant compounds. Or follow EuroPlas's blog to stay updated on the latest plastic usage trends.