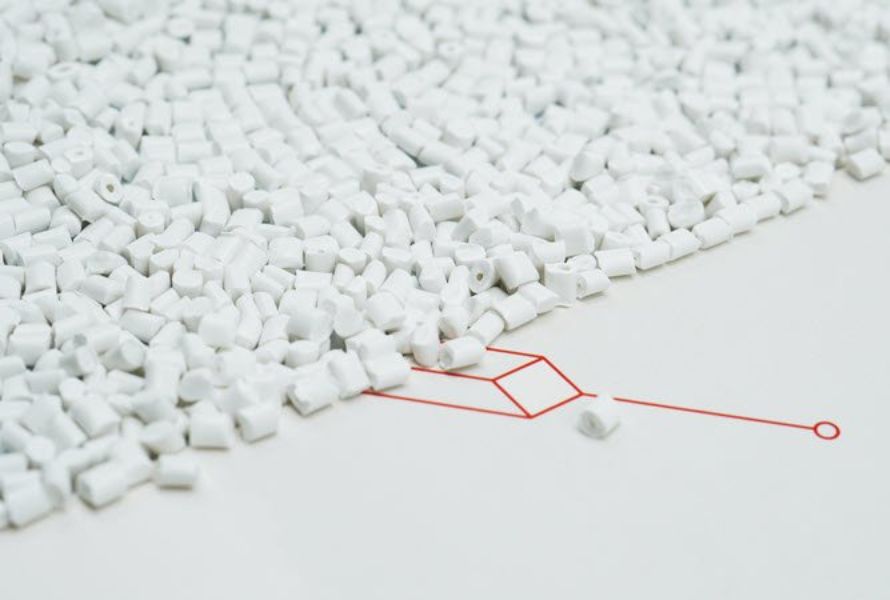

Flame retardant polypropylene is a specialized form of polypropylene that has been modified to exhibit enhanced fire resistance properties. Flame retardant polypropylene is widely used in industries where fire safety is crucial, such as automotive, electrical, and construction sectors. In this article, we will explore the key aspects of Flame retardant polypropylene, focusing on its fire resistance and thermal stability.

1. Understanding flame retardant polypropylene

Flame retardant polypropylene is a modified version of polypropylene, a thermoplastic polymer known for its advantageous characteristics such as high fire resistance, making it suitable for applications where fire safety is a primary concern.

Flame retardant polypropylene is typically produced by incorporating flame retardant additives into the polypropylene matrix during the manufacturing process. These additives can include halogenated compounds, phosphorus-based compounds, or combinations thereof. The presence of these additives imparts flame retardancy to the material.

A specific type of polypropylene that has been altered to improve fire resistance qualities is called flame retardant polypropylene

2. Key properties of flame retardant polypropylene

2.1. Fire resistance in flame retardant polypropylene

One of the key advantages of flame retardant polypropylene is its exceptional fire resistance. Flame retardant polypropylene is specifically engineered to inhibit the spread of flames and reduce the risk of fire incidents. The flame retardant additives incorporated into polypropylene play a crucial role in enhancing its fire resistance properties.

The flame retardant additives in polypropylene act through various mechanisms to disrupt the combustion process and suppress flame spread. Halogenated compounds, such as bromine or chlorine, are commonly used as flame retardants in Flame retardant polypropylene. When exposed to fire, these halogenated compounds undergo chemical reactions that release gas, such as hydrogen bromide or hydrogen chloride. These gas dilute the oxygen concentration in the combustion zone, thereby inhibiting the flame propagation process. Additionally, the released gas can act as free radical scavengers, interrupting the chain reactions that sustain the combustion process.

Phosphorous-based flame retardant additives are another commonly used option in flame retardant polypropylene. These additives can undergo thermal decomposition when exposed to high temperatures, leading to the formation of a protective char layer. This char layer acts as a barrier, shielding the underlying material from the heat and flames. It acts as an insulating layer, reducing heat transfer and preventing further flame propagation.

The combination of halogenated compounds and phosphorous-based additives in Flame retardant polypropylene can provide synergistic effects, enhancing its overall fire resistance properties. By effectively suppressing flame spread, Flame retardant polypropylene helps to mitigate the risk of fire incidents and improve overall fire safety in applications where it is utilized.

The remarkable fire resistance of flame retardant polypropylene is one of its main benefits

2.2. Thermal stability of flame retardant polypropylene

In addition to its fire resistance properties, flame retardant polypropylene exhibits excellent thermal stability, making it suitable for applications where the material is exposed to high temperatures or thermal stress.

Thermal stability refers to the ability of a material to withstand elevated temperatures without significant degradation or loss of performance. Flame retardant polypropylene is designed to maintain its structural integrity and mechanical properties even when subjected to prolonged exposure to heat.

The inherent molecular structure of polypropylene provides it with good thermal stability. However, the incorporation of flame retardant additives in flame retardant polypropylene further enhances its ability to withstand high temperatures. These additives serve to increase the material's resistance to thermal degradation and prevent premature breakdown when exposed to heat sources.

The thermal stability of flame retardant polypropylene is crucial in applications where the material may encounter elevated temperatures, such as in electrical systems, automotive components, or industrial settings. By retaining its structural integrity and performance under challenging thermal conditions, flame retardant polypropylene ensures the reliability and longevity of the products in which it is used.

Apart from its fire resistance characteristics, Flame retardant polypropylene demonstrates exceptional thermal stability

3. Applications of flame retardant polypropylene

3.1 Automotive industry

Flame retardant polypropylene finds widespread use in the automotive industry, particularly in interior components that require high fire safety standards. Dashboard panels, seat trims, door panels, and other interior parts are often made from flame retardant polypropylene. These components are in close proximity to passengers and are vulnerable to ignition sources. In the event of a fire, flame retardant polypropylene helps to inhibit the spread of flames, reducing the risk of passenger injury and improving overall safety. Additionally, flame retardant polypropylene is designed to minimize smoke generation, which helps maintain visibility and facilitates safe evacuation in emergency situations.

The automotive industry uses Flame retardant polypropylene extensively, especially for interior components that have to meet strict fire safety regulations

3.2 Electrical and electronics

The electrical and electronics industry relies on flame retardant polypropylene due to its excellent fire resistance and thermal stability. Flame retardant polypropylene is commonly used in the insulation of cables, electrical connectors, circuit enclosures, and switches. These components are critical for the safe and reliable operation of electrical systems. Flame retardant polypropylene helps minimize the risk of electrical fires by inhibiting flame propagation and reducing the release of toxic gas. Its thermal stability ensures that the material retains its electrical insulation properties even when exposed to high temperatures, providing long-term reliability and safety in high-risk environments.

3.3. Construction materials

Flame retardant polypropylene is extensively utilized in the construction industry to enhance fire safety. Pipes, fittings, and insulation made of flame retardant polypropylene are employed in plumbing and HVAC systems to prevent the spread of fire through building services. By inhibiting flame propagation, flame retardant polypropylene helps contain fires and limit their impact on the overall structure. Flame retardant polypropylene is also used in wall coverings, roofing membranes, and insulation materials to improve the fire resistance of buildings. These applications help enhance the overall fire safety of structures and protect occupants.

3.4. Consumer goods

Flame retardant polypropylene is employed in various consumer goods to enhance fire safety and comply with regulations. It is commonly found in household appliances such as washing machines, refrigerators, and microwaves. Components made from flame retardant polypropylene, such as parts and casings, help reduce the risk of fire incidents in these appliances. Flame retardant polypropylene is also used in furniture upholstery, mattresses, and curtains to improve their fire resistance properties. By incorporating flame retardant polypropylene into these consumer goods, manufacturers can ensure a higher level of safety for consumers and meet regulatory requirements.

Many consumer products use flame-retardant polypropylene to improve fire safety and adhere to regulations

3.5. Industrial applications

In industrial settings where fire safety is critical, flame retardant polypropylene is widely used. It is employed in enclosures for electrical equipment, control panels, and industrial machinery. These components are often located in environments where the risk of fire is high, such as chemical plants or manufacturing facilities. Flame retardant polypropylene helps prevent the spread of fire in these areas by inhibiting flame propagation. Its fire resistance properties ensure the protection of personnel, equipment, and critical infrastructure, reducing the potential for accidents and minimizing downtime.

3.6. Transportation and aerospace

Flame retardant polypropylene plays a crucial role in transportation and aerospace applications, where fire safety is of paramount importance. It is extensively used in the manufacturing of aircraft interiors, railway components, and mass transit systems. Flame retardant polypropylene helps meet stringent fire safety regulations and enhances passenger safety. In the event of a fire, flame retardant polypropylene inhibits flame spread and reduces smoke generation, providing passengers with valuable time for evacuation. Its use in transportation and aerospace applications ensures the highest level of fire safety and contributes to the overall integrity of these systems.

3.7. Medical and healthcare

Flame retardant polypropylene finds various applications in the medical and healthcare sector. It is used in the manufacturing of medical equipment housings, hospital furniture, and patient-care products. The fire resistance of flame retardant polypropylene is crucial in these applications, as it ensures the safety of patients, healthcare professionals, and critical medical equipment. By using flame retardant polypropylene, manufacturers can reduce the risk of fire incidents and improve the overall fire safety of healthcare facilities. This contributes to maintaining a safe environment for patients and healthcare providers.

Numerous uses for flame-resistant polypropylene can be found in the healthcare and medical industries

4. Flame retardant polypropylene of EuroPlas

EuroPlas offers a range of flame retardant polypropylene (PP) compounds with different UL94-standard flame retardant levels, including 5VA, 5VB, V0, V1, and V2. Our team of technicians works closely with customers to understand their specific requirements and create a compound that meets their desired properties.

As a trusted partner to thousands of companies worldwide, EuroPlas is committed to delivering the highest-quality products to our clients. We pride ourselves on our excellent features and capabilities in producing PP flame retardant compounds.

5. Conclusion

Flame retardant polypropylene offers significant advantages in terms of fire resistance and thermal stability. Its incorporation of flame retardant additives enables it to inhibit flame spread and enhance fire safety. Additionally, flame retardant polypropylene's thermal stability ensures its performance and integrity even under high temperatures. With its wide range of applications and ongoing advancements, flame retardant polypropylene continues to be a reliable choice for industries where fire safety is paramount.

If you want to explore our products, contact us right now or view the blog for more information about the plastic industry!