Glass-filled polypropylene plastic is one of the most popular materials in industry, used to create familiar objects around us. So, what is this material? Why does it play such an important role? This article will explain in detail the definition, characteristics and specific effects of glass-filled polypropylene.

1. What is Glass-Filled Polypropylene?

First of all, what is polypropylene plastic? Polypropylene plastic (PP plastic for short, chemical formula (C3H6)n) is a form of polymer resin created from the polymerization of propylene. PP plastic beads are usually colorless, odorless, tasteless, and especially non-toxic to health. With outstanding advantages such as cheap price, high elasticity, good chemical resistance and good electrical and thermal insulation, PP plastic is popular and used to produce household items such as food storage boxes, or other heavy industrial products such as electronic components.

In the manufacturing industry, in order to match some output products that require higher quality than usual, manufacturers will mix into PP plastic with glass fiber or glass beads. These two different forms of glass enhancement are inherently tough and durable, so when mixed, glass-filled polypropylene materials become lighter and stronger.

Glass-filled polypropylene plastic is one of the most common elements in manufacturing industry.

2. Properties of glass-filled polypropylene

Glass-filled polypropylene composed of three main elements:

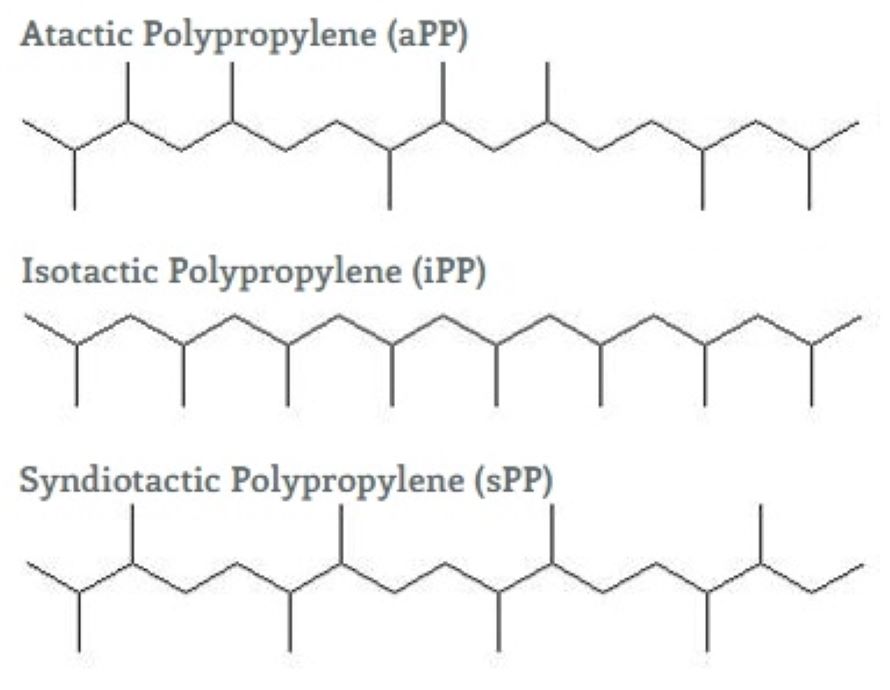

PP plastic: created from the Ziegler-Natta polymerization or metallocene polymerization. After this process, depends on the position of the methyl group, PP plastic can create three basic structures:

- Atactic (aPP): The arrangement of the methyl group (CH3) is irregular.

- Isotactic (iPP): The arrangement of the methyl group is on one side of the carbon chain.

- Syndiotactic (sPP): The arrangement of the methyl group is alternating.

Depends on the position of the methyl group, PP plastic can create three basic structures.

Glass: depending on the output product, manufacturers can choose to mix glass fibers or glass beads to the glass-filled polypropylene. The PP plastic itself has been appreciated for its durability, so after being reinforced by these types of glass, their quality becomes even more perfect.

Other ingredients: Other additives to the glass-filled polypropylene include: flame retardant, anti-UV, deodorant, anti-static, hygroscopic,...

3. Application of Glass-filled Polypropylene

Because of the affordable price, they are also used in consumer goods, including household appliances and furniture. Businesses in the hotel industry, especially resorts - their tables and chairs are outdoors to serve guests coming to the resort, prefer tables and chairs made of PP plastic mixed with UV resistant glass. In addition, toy manufacturers use PP plastic mixed with glass because of the low cost of input, and this plastic itself is inherently free of chemical toxicity without the need to add odorless and tasteless additives, from which the output product will be safe for children.

.jpg)

Resorts prefer to use furniture made from glass-filled polypropylene plastic.

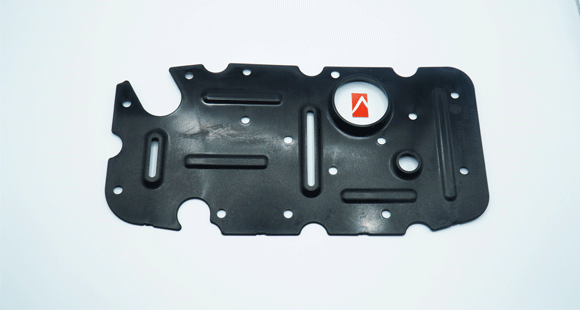

Glass-filled polypropylene plastic is also used in the automotive industry thanks to its good heat resistance, expansion and impact resistance. Specifically, glass-mixed PP plastic is used to make battery boxes, fuel tank covers, interior decoration and bumpers. In addition, the medical industry also chooses PP plastic mixed with glass to make the material for medical items, the most common are syringes. Other applications include medical vials, intravenous vials,...

Fuel tank cover is also made of glass-filled polypropylene plastic.

4. Introduction of EuroPlas Glass-filled Polypropylene

Glass-filled polypropylene plastic is one of the key products of EuroPlas. At EuroPlas, we provide customers with two different glass-phased PP plastic solutions:

PP glass bead compound is a combination of PP resin, glass beads, and other additives. The advantages of glass beads are transparency, compressive resistance, and high thermal stability thanks to their spherical shape. In addition, glass bead reinforcement can also improve the mechanical stress under load.

Using PP glass bead compound, manufacturers can increase your products’ stiffness, transparent shaping, compression resistance, and thermal stability. With those properties, this material is widely used in car interiors, home interiors, and home appliances.

PP glass bead compound has many advantages, thanks to its spherical shape.

PP glass fiber compound is made of PP base resin, glass fiber, and other additives. It gives the final products flexural modulus enhancement and more tensile strength. With those high-performance properties, glass fiber-reinforced polypropylene delivers superior strength for furniture, electric appliances, and automobile applications.

EuroPlas provides a wide range of PP glass fiber compounds with different densities of glass fiber, including ECP PP 10GF, ECP PP 20GF, ECP PP 30GF, ECP PP 40GF, and ECP PP 50GF.

.jpg)

PP glass fiber compound helps the output product has flexural modulus enhancement and more tensile strength.

At EuroPlas, the company provides a masterbatch solution tailored to the production needs of its customers. Possessing modern machinery and a team of experienced professionals, EuroPlas always provides high quality products and strives to satisfy customers at the highest level. Please contact EuroPlas for product questions, or if you have specific needs about your next project.