Nylon and synthetic fibers are one of the leading materials in the world fashion industry

Nylon and synthetic fibers are one of the leading materials in the world fashion industry.Nylon has been a part of the fashion landscape since the 1930s with great success in the US and has spread widely around the world until today. With its outstanding ability to be durable, lightweight, comfortable and adaptable to a variety of costume designs, Nylon becomes the ideal choice for the daily garment industry. Furthermore, many fashion shows have chosen to combine Nylon fabric with other materials to create costumes that are both highly aesthetic and flexible in application. Understanding the impacts of Nylon in the fashion industry in particular and the human production industry in general will be a bridge to many significant economic benefits!

1. Nylon in the Fashion Industry

Nylon and most synthetic plastic materials will be constructed from polyamides

Developed in the 1930s by a group of American chemists working for E.I. du Pont de Nemours & Company, Nylon and synthetic plastic materials in general are developed and widely applied in many different industries, especially the fashion industry.

In terms of structure, Nylon and most synthetic fibers will be constructed from polyamides produced in the form of fibers with high molecular weight and mass. Polyamides in Nylon are usually the result of the combination of dicarboxylic acids and diamines or from amino acids (self-condensing or lactams). In addition, two common active ingredients for synthesizing Nylon can be mentioned as adipic acid and hexamethylenediamine. These lines of synthetic substances are becoming increasingly strong and stimulating the research of many scientists and investors on polymers. Based on the manufacturer's needs, the ingredient ratio can be changed to adjust the softness or toughness of the material made. Nylon and synthetic plastic materials possess unique properties with good flexibility and tension resistance. According to many studies, nylon fibers have the ability to stretch 3 to 4 times compared to their original size. That is also one of the advantages of Nylon compared to other materials.

Read more: Different types of synthetic materials

2. Historical Context

2.1 Emergence of nylon in fashion

Nylon is difficult to compare thanks to its uniqueness and novelty

In the 1930s, the launch of Nylon opened a new path for fashion around the world. In particular, in 1938 – 1939 is the peak age of Nylon, Nylon was known as one of the materials that is difficult to compare thanks to its uniqueness and novelty. Nylon's predecessor, known to everyone as artificial silk (rayon), is one of the keys to the economic success of many fashion investors. This is a huge commercial fiber material and opened a fashion revolution on an extremely large scale. Fashion products made from Nylon meet the need to optimize costs many times more than silk but still satisfy the wearer's luxurious aesthetics. Depending on usage needs, the ratio of materials during the production process will be calibrated, helping Nylon not only bring soft, comfortable clothes but also be the ideal choice for clothes that require durability, Waterproof and anti-mold. Today, under the strong development of production technology and widespread use by most consumers in the world, Nylon products are present everywhere around us from the fashion industry to many other fields.

2.2 Introduction of nylon stockings and garments

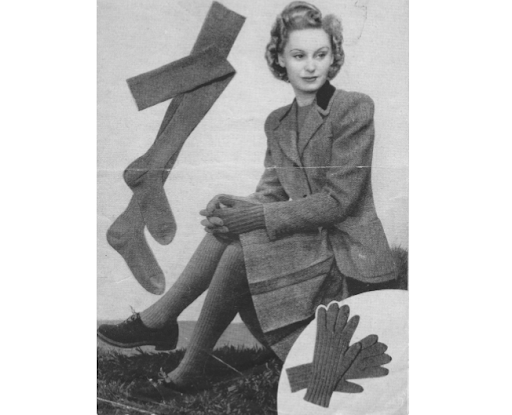

Nylon socks were first introduced and received a strong response from American

Before the advent of Nylon, most stockings and garments were produced primarily from silk or cotton. Before the 1930s, Japan developed strongly in silk materials and was a source of silk for the US and many other countries around the world. In particular, the US is the largest consumer of silk from Japan, the rate is up to about 90%, of which 3/4 of silk materials are imported by the US to use for the purpose of producing stockings. However, silk materials for stocking are not the best choice because they are thin, easy to tear and have poor impact protection. Above all, trade relations between the US and Japan became increasingly worse due to Japan's expansion at that time. This led to the American invention of a replacement for Japanese silk.

According to America's plan, the invented Nylon material was extremely well received by the people. In 1939, at the New York World's Fair, Nylon socks were first introduced and received a strong response from American citizens. The proof is that at that time all 4,000 pairs of socks with Nylon were sold out in just a few hours and about 4 million pairs of socks were sold out in just 4 days. This is a revolutionary milestone in the stockings industry. In May 1940, nylon socks were sold in stores across the United States.

2.3 Revolutionizing fashion

Nylon materials were increasingly exploited in the garment industry

After the notable event about Nylon in the US, this is also a milestone marking a revolution in garment materials on a scale that spreads widely around the world.

America's success is extremely worthy of recognition. Nylon socks products bring a comfortable feeling, fit well, hug tightly and are especially super durable for users. Nylon stockings are soft, protect and support the skin extremely well. Not only for the purpose of keeping warm and protecting the legs, nylon stockings were also considered a fashion accessory for many women at that time.

When World War II broke out, Nylon materials were increasingly exploited in the garment industry. They are woven and processed into military clothes with waterproof, mold-proof, elastic and super durable properties. A series of bulletproof armor is also produced with the contribution of Nylon. In addition, products that can be easily found include parachutes for skydiving, nylon socks, shoes and shoelaces, hammocks or anti-mosquito membranes.

Nowadays, products made from Nylon fiber have become stronger and stronger. Fashion products made from Nylon meet the sophisticated and beautiful processing process but still meet the price suitable for all classes.

3. Nylon's versatility in design and applications

3.1 Diverse applications of nylon

In general, Nylon is widely used in various industries and manufacturing fields today. It is thanks to its flexibility and great economic efficiency that Nylon is so popular. Here are some areas where nylon makes a huge contribution:

Nylon is very flexible in garment applications suitable for all ages

- Garment industry: Nylon is very flexible in garment applications suitable for all ages. Designs such as clothes, shoes, underwear, raincoats, swimwear, sportswear, etc. These products are very popular and widely used around the world.

- Fashion accessories industry: Nylon is a reliable choice for designs that require high formability. Today's materials help manufacturers easily shape designs from simple to complex. Applications that can be easily found include bags, belts, hats, socks, gloves, etc

- Automotive industry: applications include gears, bearings, bodywork, water pump impellers, wheel covers, exterior dashboards, oil tanks, cylinder heads, radiators, oil & water tanks. Thanks to the flexibility and durability of this material, the above designs are always very popular.

- Electronics - components industry: thanks to its flexibility in design and installation, Nylon is used to produce connectors, component holders, plug-ins and some electrical circuit protection covers.

- Civilian materials: Nylon is present in many devices you use every day such as hammocks, tents, bags, toothbrushes and some other common materials such as tennis racket strings, fishing nets, guitar strings -ta, picture frames,... Everyday materials made from Nylon always meet durability over many years.

- Medical industry: Nylon is used to manufacture some pipes, protective bags and waste bags. Their price is quite cheap and suitable for disposable applications. In particular, its moisture-proof and dry properties help limit mold and infection

3.2 Advancements in textile technology

The advancement in textile technology that Nylon brings is undeniable. They are increasingly popular and have become the ideal material to meet many diverse fashion uses of people. The appearance of nylon has replaced other materials not only in the field of stockings but also in the garment industry, especially for women. The advances in textile technology that Nylon material brings to us can be listed as follows:

Nylon is considered a material that can retain color extremely well

- High durability and limited wrinkles: clothes will easily wrinkle after washing, Nylon material is the solution to this situation. Nylon will minimize wrinkles on clothes, helping you save a lot of time and electricity for ironing every day.

- Affordable price: Synthetic nylon material is not too expensive and can meet the needs of mass production. Nylon fabric sources and markets meet very reasonable prices for many families. Depending on usage needs, consumers can choose from a variety of models, sizes, and designs at many affordable prices.

- Long-lasting color: Nylon is considered a material that can retain color extremely well. The ability to adhere to color makes the process of dyeing Nylon fabric quick and cost-effective. Besides, the color fastness of the fabric helps the outfit always maintain its fresh color through many washes.

- The product has a long lifespan: thanks to the toughness and durability of polymers and synthetic components. They limit tearing or deformation due to stretching.

- Moisture-proof: this helps clothes avoid mold and mildew, helping to limit most bacteria that cause unpleasant odors. Nylon fabric absorbs moisture quite low, so it dries quickly after washing, helping to bring a pleasant dry feeling on the skin.

3.3 Nylon's role in designing apparel

Nylon's role in designing apparel is increasingly affirmed. The key roles that this material plays in the garment industry include:

Nylon saves most costs and brings significant profits

- Diverse costume designs: Nylon contributes to the diversity of designs from simple to sophisticated. Thanks to properties such as durability, lightness, dryness and ease of shaping, Nylon is suitable for many designs such as clothes, dresses, socks, raincoats, sportswear and even swimwear. Due to its extremely flexible application, Nylon is gradually appearing in all forms of clothing for many ages.

- Eye-catching color design: thanks to the color-adhering properties, the fabric dyeing process becomes quick and easy. Nylon fabric can be dyed in all colors and the color level is extremely standard. Color durability is a plus point that helps clothes always maintain their fresh colors even after being washed many times.

- Role in economic efficiency: this is one of the top goals that investors set. Replacing the majority of garment materials to Nylon saves most costs and brings significant profits. Besides, price is also one of the things that consumers care about when deciding to use Nylon fabric.

3.4 Aesthetic contributions to fashion

Women love flared dress designs and Nylon is an ideal choice

Nylon has made significant aesthetic contributions to fashion. Since the 1930s, the presence of Nylon solved the huge supply of materials for America, and people began to care more about the aesthetics of the product. Stockings are becoming more and more beautiful with many designs and colors. Women love flared dress designs and Nylon is an ideal choice. The dresses are sewn from Nylon fabric to create a flared look, combined with a belt to help accentuate a woman's perfect waist.

Continuing the craze called Nylon fabric, to this day, Nylon is always the top choice for the garment industry. Nylon fabric is suitable for most designs on the market from flared short dresses, long sundresses, or even designs for men. Nylon appears more in fashion shows with costumes that meet both beauty and practicality. The aesthetics of Nylon fabric is affirmed through its diverse colors and ease of shaping during the sewing process.

4. Challenges and criticisms

The development of Nylon also brings impacts on the environment

4.1 Environmental concerns

The development of Nylon also brings concerns about the impact of this material on the environment. Nylon material has a quite positive impact on the environment in reducing waste after use from less durable materials. However, the Nylon fabric production process also brings negative effects to the environment. To minimize these negative effects, we need more effective and safer measures to treat Nylon waste.

4.2 Shifts in fashion sustainability

In an era when people are promoting the importance of environmental protection, Nylon must face certain challenges. The balance in use between Nylon and other materials can contribute to cost optimization and environmental protection.

5. Conclusion

In conclusion, Nylon has created a fashion revolution and gradually asserted its role in the fashion industry worldwide. In today's era, Nylon still continues its success and maintains its position in the hearts of consumers thanks to its outstanding features and significant cost benefits. Please continue to follow EuroPlas's diverse articles on materials knowledge to update useful information every day!