In the world of interior design and DIY projects, the allure of natural wood is undeniable. Its warmth, texture, and timeless appeal can transform any space. But what if we told you that you can achieve the same captivating wood-like aesthetics on plastic surfaces?

Welcome to the guide on how to make plastic look like wood. Whether you're upcycling furniture, adding a rustic touch to your home decor, or just unleashing your creative flair, this guide is your key to mastering the art of faux wood finishes.

From essential materials and techniques to valuable tips and tricks, we'll walk you through the entire process. So, let's roll up our sleeves and embark on a journey that combines creativity and ingenuity, proving that with the right know-how, plastic can be transformed into something truly extraordinary.

1. Materials and tools you need

Transforming plastic into a wood-like appearance can be a fun and creative project, whether you're working on DIY crafts or home improvement. To get started, you'll need a few essential materials and tools. Here's a comprehensive list of what you'll require:

1.1. Materials:

- Plastic Surface: Select the plastic object or surface you want to make look like wood. This could be anything from a piece of furniture to PVC pipes, planters, or even toys.

- Primer: A good-quality primer will help the paint adhere to the plastic surface effectively. Choose a primer suitable for plastic materials.

- Wood Grain Tool: This tool is essential for creating the realistic wood grain pattern. You can find wood grain tools in various shapes and sizes, depending on the level of detail you want.

- Acrylic Paints: Choose acrylic paints in wood-like colors, such as shades of brown, tan, and black. These will form the base coat for your wood grain effect.

- Paintbrushes: A variety of paintbrushes, including fine detail brushes and broader brushes for background work.

- Sandpaper: You'll need sandpaper to smoothen the plastic surface and create a more authentic texture.

- Clear Sealant: A clear sealant or varnish will protect your painted wood grain effect and add a glossy finish.

1.2. Tools:

- Sanding Block: A sanding block will make the sanding process easier and more consistent.

- Paint Tray: To mix and hold your acrylic paints.

- Drop Cloth or Newspaper: To protect your workspace from paint splatters and spills.

- Cleaning Supplies: Mild soap, water, and a clean cloth for cleaning the plastic surface before starting.

Gathering these materials and tools is the first step in achieving a convincing wood-like finish on plastic. Once you have everything ready, you can proceed with the step-by-step process of creating a wood grain effect on your plastic item.

2. Guide on how to paint plastic to look like wood

Creating a wood-like appearance on plastic can be a fascinating and rewarding endeavor. With the right techniques, you can achieve a remarkably realistic wood grain effect. Here's a step-by-step guide on how to make plastic look like wood:

Step 1: prepare the surface

- Clean the plastic: start by cleaning the plastic surface thoroughly. Use a mild soap and water to remove any dirt, grease, or contaminants. Rinse and dry it completely before proceeding.

- Sand the surface: use sandpaper to roughen the plastic surface slightly. This helps the primer adhere better and provides a texture that mimics wood grain.

Step 2: apply primer

- Choose the right primer: select a primer specifically designed for use on plastics. Apply an even coat of primer to the plastic surface and allow it to dry completely. This step ensures that the paint will bond well with the plastic.

Step 3: create the base coat

- Select wood-like colors: choose acrylic paints in wood tones. Typically, you'll want to use varying shades of brown, tan, and black. Apply a base coat of the lightest brown paint and let it dry.

Step 4: adding the wood grain

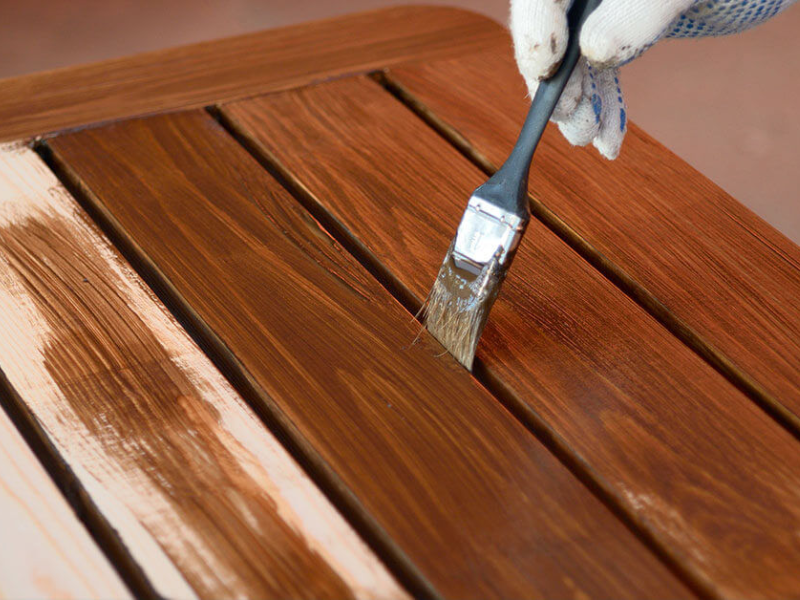

- Use a wood grain tool: this is where the magic happens. Take your wood grain tool and dip it into a darker brown paint. Gently drag the tool across the surface, creating wavy lines and grain patterns. Experiment with different pressures and directions to achieve a realistic look. Remember that real wood grain isn't uniform, so embrace some variation in your lines.

Step 5: adding depth

- Layering: to add depth and dimension, you can repeat the wood grain tool process with progressively darker paint shades. This creates a more intricate and authentic wood grain effect.

Step 6: finishing touches

- Dry and seal: allow the paint to dry completely, which may take several hours. Once dry, apply a clear sealant or varnish to protect the finish and provide a glossy sheen.

- Optional aging effects: for a weathered wood appearance, lightly sand the surface in random spots. This will expose the base coat and create a weathered effect.

With patience and practice, you can transform plastic into a stunning wood-like finish. Whether you're looking to update your home decor or revamp plastic outdoor furniture, this guide on how to paint plastic to look like wood allows you to enjoy the aesthetic appeal of wood without the expense or maintenance. The key is to experiment, embrace imperfections, and let your creativity flow.

3. Tips and tricks on how to make plastic look like wood

While creating a wood-like finish on plastic can be an exciting project, achieving a convincing result often requires attention to detail and some helpful tips and tricks. Here are some valuable insights to make plastic look like wood like you want it to be:

3.1. Study real wood grain:

Before you start, study actual wood grain patterns in various types of wood. Pay attention to the lines, knots, and variations in color. This observation will help you mimic a more realistic wood texture.

3.2. Experiment with colors:

Don't limit yourself to one shade of brown. Real wood has a spectrum of colors within its grain. Experiment with a range of brown tones, adding a touch of black and tan for depth and authenticity.

3.3. Vary your strokes:

Wood grain is rarely perfectly uniform. When using the wood grain tool, vary the pressure, direction, and length of your strokes to create natural irregularities. This will make your plastic surface look more like real wood.

3.4. Dry brushing technique:

To mimic the look of aged or weathered wood, try dry brushing. Use a nearly dry brush to lightly apply a darker color on top of your base coat. This will create a worn appearance and enhance the wood-like effect.

3.5. Layering:

Layering is key to achieving depth and richness in the wood grain. Apply several coats of paint and let each one dry before adding more. Gradually build up the wood grain effect with darker colors for a more realistic appearance.

3.6. Use reference images:

Keep reference images of real wood nearby while you work. This can serve as a visual guide, helping you recreate specific wood species or styles accurately.

3.7. Practice on test surfaces:

Before tackling your main project, practice your wood grain technique on a spare piece of plastic or a hidden area. This will help you refine your skills and gain confidence.

3.8. Don't rush the drying process:

Allow sufficient time for each coat of paint to dry. Rushing this step can lead to smudging or uneven results.

3.9. Top it off with varnish:

Once you've achieved your desired wood grain effect, apply a clear sealant or varnish to protect your work. This not only enhances the realism but also provides durability.

3.10. Be patient and have fun:

Creating a wood-like finish on plastic is a creative process that may take some time to master. Enjoy the journey, embrace the imperfections, and remember that practice makes perfect.

With these tips and tricks to make plastic look like wood, you'll be well on your way to transforming ordinary plastic surfaces into stunning wood-like textures that can enhance your home decor or any diy project you undertake.

When it comes to sourcing top-quality plastic solutions that excel in both performance and sustainability, EuroPlas stands as a global leader in the industry. With over 15 years of expertise, EuroPlas has earned a stellar reputation for providing innovative and eco-conscious products to customers in more than 85 countries.

As a masterbatch manufacturer based in Vietnam, we pride ourselves on our advanced facilities, unique natural resources, and cutting-edge technology, all of which allow us to customize products for a wide array of industries and applications. At EuroPlas, we are unwavering in our commitment to shaping a sustainable future, offering cost-effective and eco-friendly options that meet the ever-evolving needs of our global clientele.

One of our flagship products is the EuroPlas Bioplastic Compound, which embodies our dedication to environmental sustainability. Crafted from natural starch and biodegradable additives, this unique compound not only retains exceptional performance but also enables plastic items to biodegrade within a year. This makes it a superb choice for applications in food packaging, agricultural films, and a multitude of industries, contributing significantly to a greener, eco-friendly future.

In line with our sustainability commitment, EuroPlas proudly offers the Bio Filler, an eco-friendly alternative that renders plastic items biodegradable within a year. Comprising natural starch and biodegradable additives, our Bio Filler is ideal for applications in food packaging, disposable tableware, and agricultural films. It provides a sustainable choice that promotes environmental consciousness without compromising product performance.

Our Filler Masterbatch is a game-changer for industries seeking to reduce production costs while enhancing the properties of plastic products. By substituting a portion of virgin resin with filler materials such as calcium carbonate or talc, this product improves stiffness, heat resistance, opacity, and printability. It finds applications in blowing films, injection molding, extrusion, and thermoforming, making it an indispensable component in various sectors.

At EuroPlas, we understand the importance of aesthetics. Our Color Masterbatch offers exact and consistent colors for toys, household appliances, cosmetics, and more. With high-quality pigments and additives that can be blended with various resins, we ensure that your products exhibit vibrant and appealing designs that align perfectly with market demands.

Our range of Plastic Additives plays a crucial role in enhancing production efficiency and functionality for films, pipes, and cables. With a comprehensive suite of agents like slip, anti-block, anti-static, anti-oxidants, and UV stabilizers, EuroPlas' additives improve the performance and longevity of plastic products while contributing to sustainability by reducing waste.

For those seeking high-performance plastic solutions that meet rigorous industry standards, EuroPlas offers Engineering Plastic Compounds. These all-in-one solutions combine engineering resins with various additives to enhance the mechanical, thermal, electrical, optical, and chemical properties of plastic products. Whether for automotive parts, electronic components, or medical devices, EuroPlas' Engineering Plastic Compounds consistently outperform competitors, ensuring quality and reliability.

EuroPlas is your steadfast partner in embracing the future of plastic materials — a future characterized by excellence in performance and a deep commitment to environmental responsibility. With our diverse product range and unwavering dedication, we look forward to serving your plastic needs and being a part of your journey toward a more sustainable tomorrow. Contact us now for more information!