Similar to other plastic materials such as PC or PP. Consumers are also skeptical about the safety and quality of Polyurethane plastic, or PU. In this article, EuroPlas will help you answer the question "What is PU plastic?" and "Is polyurethane plastic toxic?". Please refer to EuroPlas!

Is Polyurethane plastic toxic?

Polyurethane plastic is one of the popular materials in heavy industries. The material is formed thanks to the close connection of organic units through Carbamate (Urethane).

In particular, if you know the Polymer component of money, this is an upgraded version of that material. The process of synthesizing PU compounds will make this plastic line possess higher durability as well as have similar characteristics to natural rubber lines on the market. That is why they are also called artificial rubber.

Besides, the molecular structure of Polyurethane plastic has two parts: hard and soft. Isocyanate will be the main component that makes up the hard structure of PU plastic. Meanwhile, the software will be linked by Polyol.

The PU plastic production process is guaranteed to be safe and possesses all necessary legal procedures

Therefore, Polyurethane plastic not only has the elasticity of rubber but is also flexible in hard or soft state during the production process.

EuroPlas has partly answered customers' questions related to the question "What is PU plastic?" In the next section, we will provide reasons why PU plastic is popular? and is Polyurethane plastic toxic?

2. 6 reasons why PU plastic is popular on the market.

- First, the close connection of chemical elements and mechanical support units helps PU plastic form protective layers. Because of this, they can resist ultraviolet rays, water, oil and other chemical impurities.

- Second, because PU plastic is known as artificial rubber, it has 3-5 times better elasticity than natural rubber. Besides, the abrasion resistance properties of the material are also very well inherited from rubber.

- Thirdly, because metal is also one of the important materials in the composition of PU plastic, the material has great bearing capacity and stable hardness over time. Based on the Shore method, the hardness of PU plastic reaches SHORE A80 - 95. This is quite high compared to conventional plastics.

- Fourthly, the composition of PU plastic synthesizes both metal and rubber, so Polyurethane plastic inherits the characteristics of these two material lines. That is the reason why PU plastic has a fairly large heat resistance range from minus 40 degrees Celsius to more than 80 degrees Celsius and is familiar in harsh working environments.

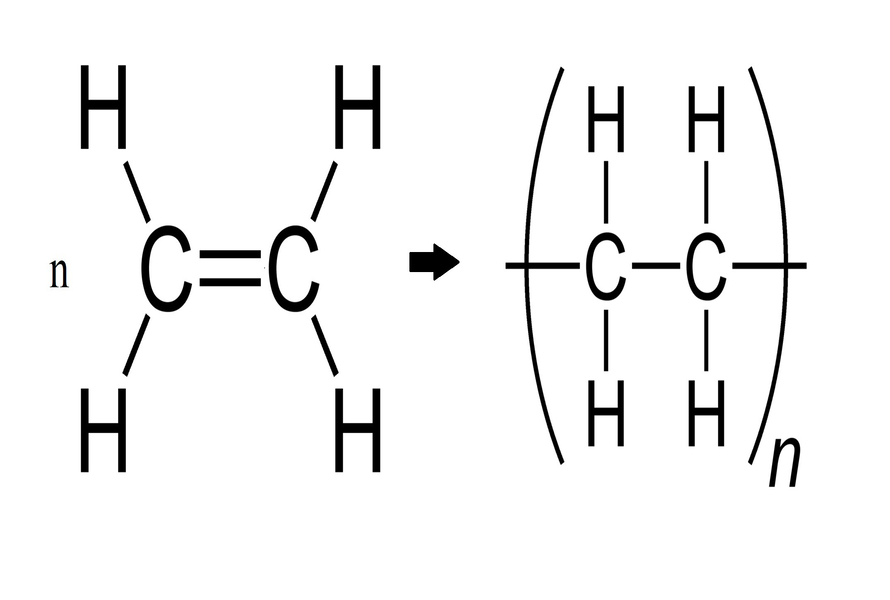

The chemical structure of PU plastic

- Fifthly, Polyurethane plastic has very good electrical insulating properties. Because the composition includes organic polymers combined with Carbon, Hydrogen and other additives. The electrons of the atom will be completely occupied by the tight bond of the plastic molecules. This eliminates free Electrons and their ability to conduct electricity.

- Finally, Polyurethane plastic has perfect bearing capacity and reaches very high traction levels. Large industrial parks must use pulling forces of over 500lbs/inch to break this material. Overall, PU plastic materials possess all the superior characteristics of industrial materials. Therefore, they are commonly used in many fields such as: Manufacturing, Minerals, Fashion or Automotive.

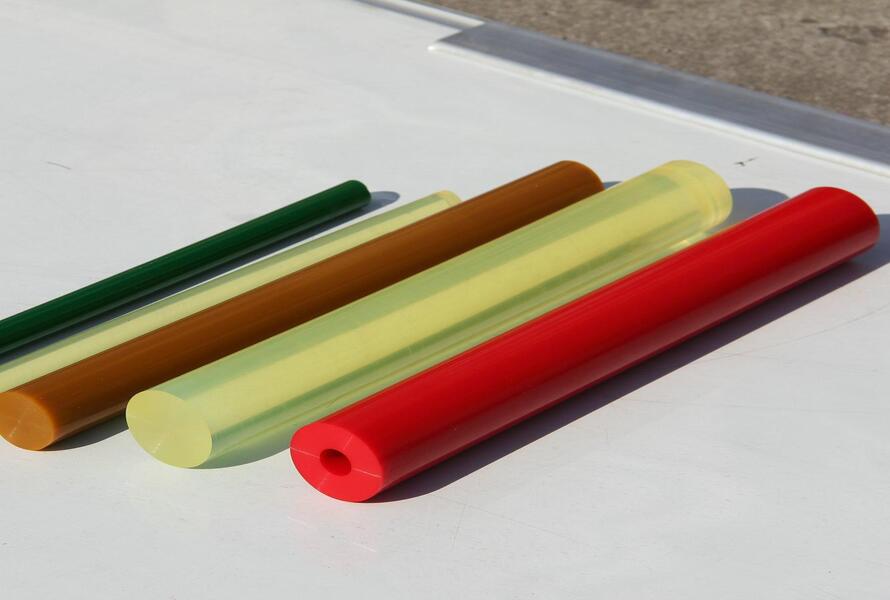

Polyurethane plastic is used in many areas of life

Polyurethane plastic is used in many areas of life

In the next part, EuroPlas will show customers the great applications of PU plastic in various fields.

Read more: All information about the Polyurethane plastic

3. Common applications of Polyurethane plastic

- The ability to withstand heat and force has helped PU plastic become an important component in the production of industrial machines. Some common applications are: textile machines, printers or photocopiers.

- Besides, with good abrasion and force resistance as well as resistance to impurities, PU plastic is well utilized in the metallurgy, oil exploitation and construction materials industries. In particular, PU plastic can be affected by weather without any quality problems.

- Stable elasticity and tensile strength over time are also strong points that help Polyurethane plastic be used to make springs and buffers in vehicles. In addition, they can be utilized to produce pulley equipment for transporting large goods.

PU plastic used in industri al production

- In addition, the automobile industry also uses PU plastic to make swimming wheels because of their anti-scaling, anti-abrasion properties and thickness. This increases the safety rate for vehicles on long journeys. Besides, specialized F1 racing cars also use tires made from PU plastic material.

- Currently, PU plastic is improved into fiber form and combined with Carbon and Nylon to create clothing collections. The lightness and breathability of PU plastic fibers make clothes more convenient for consumers.

- In the construction materials industry, PU plastic is combined with high-quality Alkyd to make PU paint. Therefore, this paint line also has the ability to adhere well to metal surfaces, is not affected by weather and resists discoloration after a long time. Besides application, PU paint is suitable for most interior materials such as wood, metal, ceramics,... In particular, scientists are in the process of researching and testing wood-imitation PU plastic products. . This is a good replacement product for natural wood, contributing to protecting the environment, protecting consumer health and saving businesses' production costs.

- High strength with pressure of over 50 tons makes Polyurethane material a suitable choice for hydraulic compressors or specialized pumps with high capacity. This still ensures that the machine is not deformed after a long period of production.

PU plastic pipe products

EuroPlas introduced in great detail "What is PU plastic?" and their outstanding features. Besides, to answer the question "Is PU plastic toxic?", let's choose an example product line of PU plastic to see their characteristics. EuroPlas will choose the PU Paint line.

4. Is paint made from PU plastic materials toxic?

PU paints are considered not to affect human health because they have undergone a preparation process to remove unnecessary chemical impurities. However, if you do not wear adequate protective equipment and are exposed to them for a long time, PU paint also affects some health problems. As follows:

- If you do not use goggles or gloves, PU Paint may cause skin irritation with prolonged contact. Patients will experience symptoms of red rashes on the skin, itching and burning in the affected skin area.

- Besides, PU Paint also produces fine dust particles if the spraying process takes place for a long time. Fine dust particles are the main cause affecting the respiratory system and lungs if you do not wear a protective mask during construction. Therefore, experts advise that you should use PU paint in a well-ventilated environment.

PU plastic materials are tested to not contain carcinogens

- In particular, if you smell them too much and for too long, you will experience symptoms of dizziness, nausea or possibly central nervous system effects. The main reason is the amount of organic vapor contained in the composition of PU plastic.

A product that can also be mentioned is PU plastic rubber. Because Polyurethanes are made by reacting an isocyanate containing two or more isocyanate groups per molecule (R−(N=C=O)n) with a polyol containing an average of two or more hydroxyl groups per molecule (R-(OH)n) in the presence of a catalyst or by activation with ultraviolet light. Therefore, this product does not affect the health of consumers.

5. Conclusion: Is Polyurethane plastic toxic?

Almost all plastic material production processes at factories are thoroughly tested and are operated by modern equipment. In addition, business owners also need to possess all documents and procedures to ensure health safety certified by competent authorities before supplying to the market. To identify whether PU plastic is toxic, EuroPlas will develop two cases: For producers and For consumers.

5.1 For producers:

As we all know, Isocyanate and Polyol are the two main ingredients that make up PU plastic. If the Isocyanate content exceeds the allowed level, it will affect the functions of organs such as the nose, throat, lungs, eyes and skin.

Therefore, workers are recommended to be fully equipped with protective equipment before participating in the production process.

PU plastic is safe for the health of workers in the factory

5.2 For consumers:

The American Government Industrial Hygiene Association in conjunction with the Occupational Safety and Health Administration has announced that PU plastic is completely non-carcinogenic. Polyurethane plastic materials do not contain toxic substances and are suitable for application in all fields of life.

PU plastic is safe for consumers

EuroPlas has sent you information on two questions: "What is PU plastic?" and "Is polyurethane resin toxic?" Please continue to follow us to update the latest information on all industrial plastic products and related materials!